! Turn off and disconnect in- put power.

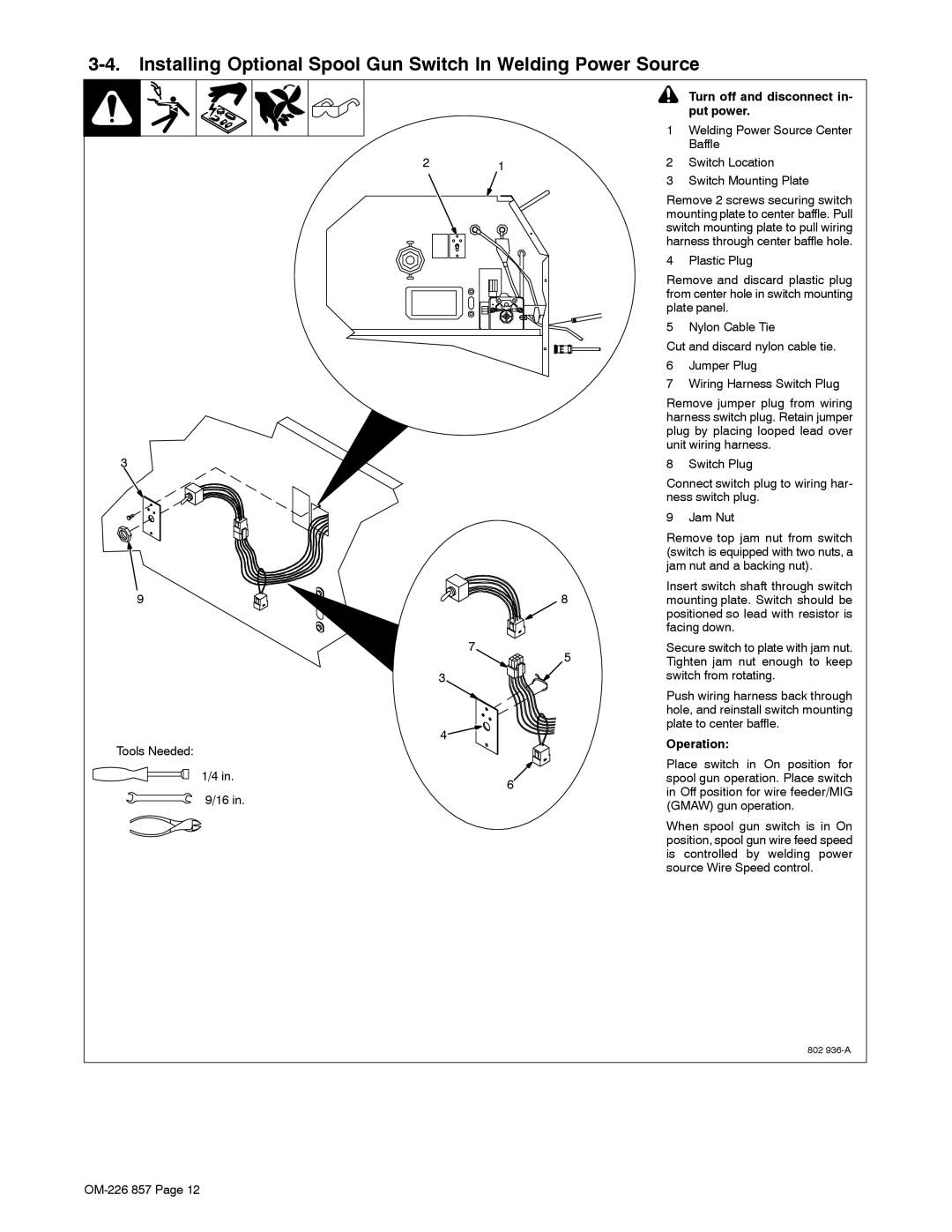

1 Welding Power Source Center

Baffle

2 | 1 | 2 | Switch Location |

|

| 3 | Switch Mounting Plate |

|

| Remove 2 screws securing switch | |

|

| mounting plate to center baffle. Pull | |

|

| switch mounting plate to pull wiring | |

|

| harness through center baffle hole. | |

|

| 4 | Plastic Plug |

|

| Remove and discard plastic plug | |

|

| from center hole in switch mounting | |

|

| plate panel. | |

|

| 5 | Nylon Cable Tie |

|

| Cut and discard nylon cable tie. | |

|

| 6 | Jumper Plug |

|

| 7 Wiring Harness Switch Plug | |

|

| Remove jumper plug from wiring | |

|

| harness switch plug. Retain jumper | |

|

| plug by placing looped lead over | |

|

| unit wiring harness. | |

3 |

| 8 | Switch Plug |

|

| Connect switch plug to wiring har- | |

|

| ness switch plug. | |

|

| 9 | Jam Nut |

|

| Remove top jam nut from switch | |

|

| (switch is equipped with two nuts, a | |

|

| jam nut and a backing nut). | |

9 | 8 | Insert switch shaft through switch | |

mounting plate. Switch should be | |||

|

| positioned so lead with resistor is | |

|

| facing down. | |

| 7 | Secure switch to plate with jam nut. | |

| 5 | Tighten jam nut enough to keep | |

| 3 | switch from rotating. | |

|

| Push wiring harness back through | |

|

| hole, and reinstall switch mounting | |

| 4 | plate to center baffle. | |

| Operation: | ||

Tools Needed: |

| ||

| Place switch in On position for | ||

1/4 in. |

| ||

6 | spool gun operation. Place switch | ||

| in Off position for wire feeder/MIG | ||

9/16 in. | (GMAW) gun operation. |

| |

| When spool gun switch is in On |

| position, spool gun wire feed speed |

| is controlled by welding power |

| source Wire Speed control. |

802