4-3. Installing Muffler Pipe

Tools Needed:

1/2 in

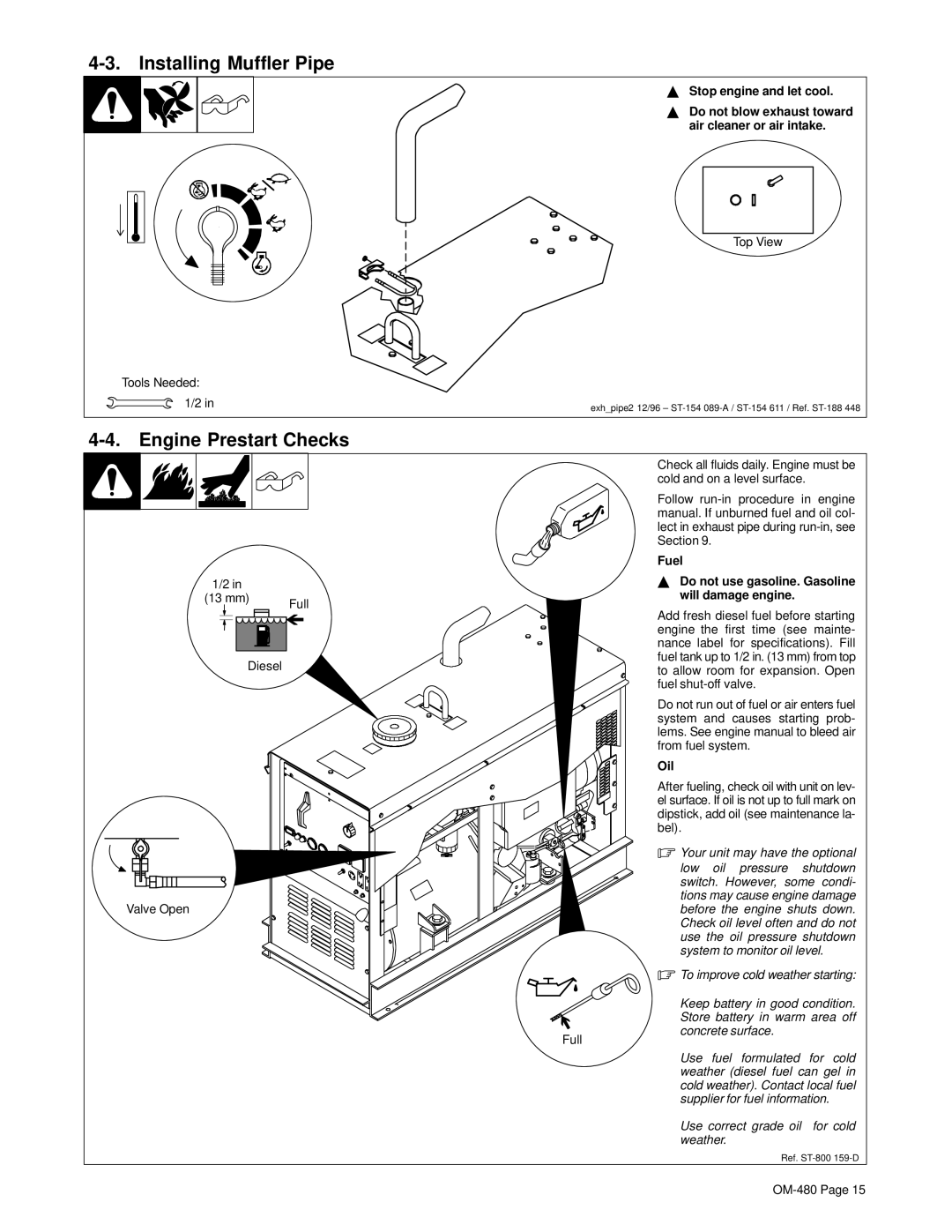

4-4. Engine Prestart Checks

YStop engine and let cool.

YDo not blow exhaust toward air cleaner or air intake.

Top View

exh_pipe2 12/96 –

1/2 in |

|

(13 mm) | Full |

| |

Diesel |

|

Valve Open

Check all fluids daily. Engine must be cold and on a level surface.

Follow

Fuel

YDo not use gasoline. Gasoline will damage engine.

Add fresh diesel fuel before starting engine the first time (see mainte- nance label for specifications). Fill fuel tank up to 1/2 in. (13 mm) from top to allow room for expansion. Open fuel

Do not run out of fuel or air enters fuel system and causes starting prob- lems. See engine manual to bleed air from fuel system.

Oil

After fueling, check oil with unit on lev- el surface. If oil is not up to full mark on dipstick, add oil (see maintenance la- bel).

. Your unit may have the optional low oil pressure shutdown switch. However, some condi- tions may cause engine damage before the engine shuts down. Check oil level often and do not use the oil pressure shutdown system to monitor oil level.

.To improve cold weather starting:

Keep battery in good condition. Store battery in warm area off concrete surface.

Full

Use fuel formulated for cold weather (diesel fuel can gel in cold weather). Contact local fuel supplier for fuel information.

Use correct grade oil for cold weather.

Ref.