5-2. Description Of Front Panel Controls (See Section 5-1)

.This unit has a max OCV control circuit that resets the Amperage/Voltage Con- trol to maximum when the arc breaks. When an arc is struck, weld output control returns to the front panel or remote con- trol setting. The Amperage/voltage Con- trol adjusts amperage only when welding and does not adjust

1 Ampere Range Switch

Use switch to select weld amperage range. For most welding applications, use lowest amperage range possible to prevent arc out- ages.

YDo not switch under load.

2 Amperage/Voltage Control

Control adjusts amperage within range selected by Ampere Range switch. Weld out- put would be 140 A DC with controls set as shown (50% of 90 to 190 A).

3DC Voltmeter (Optional)

4DC Ammeter (Optional)

5Remote A/V Switch And Receptacle

(See Section

6 Magnetic Shutdown Switch (Optional)

Use switch during

7 Engine Control Switch

To Start: turn switch to Start while pressing Shutdown switch. Release switches when engine starts.

.If the engine does not start, let engine come to a complete stop before attempt- ing restart.

In Run position, engine runs at weld/power speed. In Run/Idle position (optional), engine runs at idle speed at no load and weld/power speed with load applied.

To Stop: turn switch to Off position.

8 Battery Charging Warning Light

Light goes on when battery is not charging.

9 Oil Pressure Warning Light

Light goes on if oil pressure is too low. If unit has automatic shutdown option, light also goes on if oil temperature is too high.

YStop engine and fix trouble if either light goes on.

10 Ether Starting Aid Switch (Optional)

Push switch up and release while cranking engine to release ether.

YDo not use Ether if engine is running.

11Engine Hour Meter

12Oil Temperature Gauge/Switch (Optional)

13Oil Pressure Gauge/Switch (Optional)

14Polarity Switch (Optional)

Place switch in Straight position for electrode negative, or Reverse position for electrode positive.

15 Manual Shutoff Lever

Use lever to stop engine if engine control switch does not work.

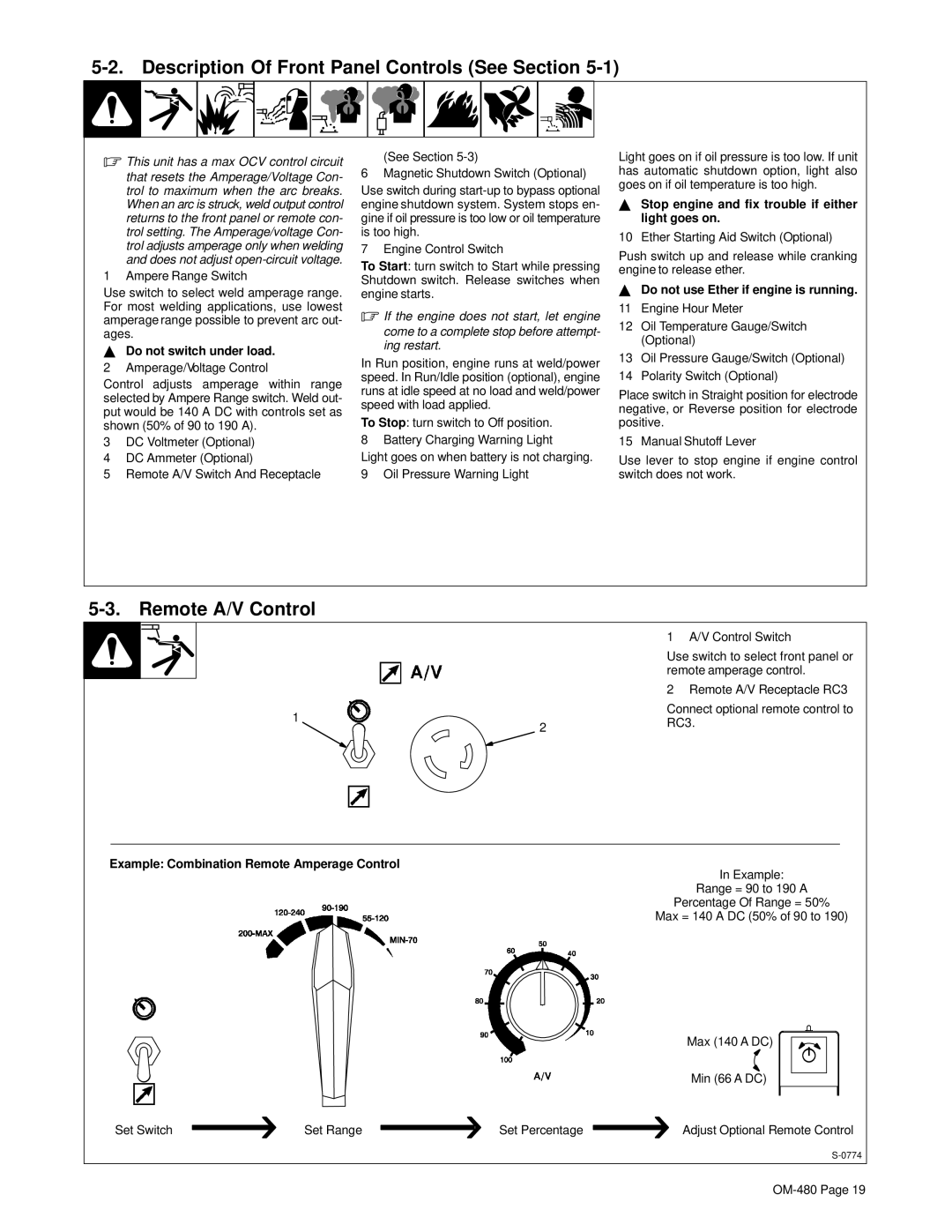

5-3. Remote A/V Control

1 A/V Control Switch

Use switch to select front panel or remote amperage control.

2 Remote A/V Receptacle RC3 Connect optional remote control to

1 | 2 | RC3. |

| ||

|

|

Example: Combination Remote Amperage Control

In Example:

Range = 90 to 190 A

Percentage Of Range = 50%

Max = 140 A DC (50% of 90 to 190)

|

|

| Max (140 A DC) |

|

|

| Min (66 A DC) |

Set Switch | Set Range | Set Percentage | Adjust Optional Remote Control |

|

|

|