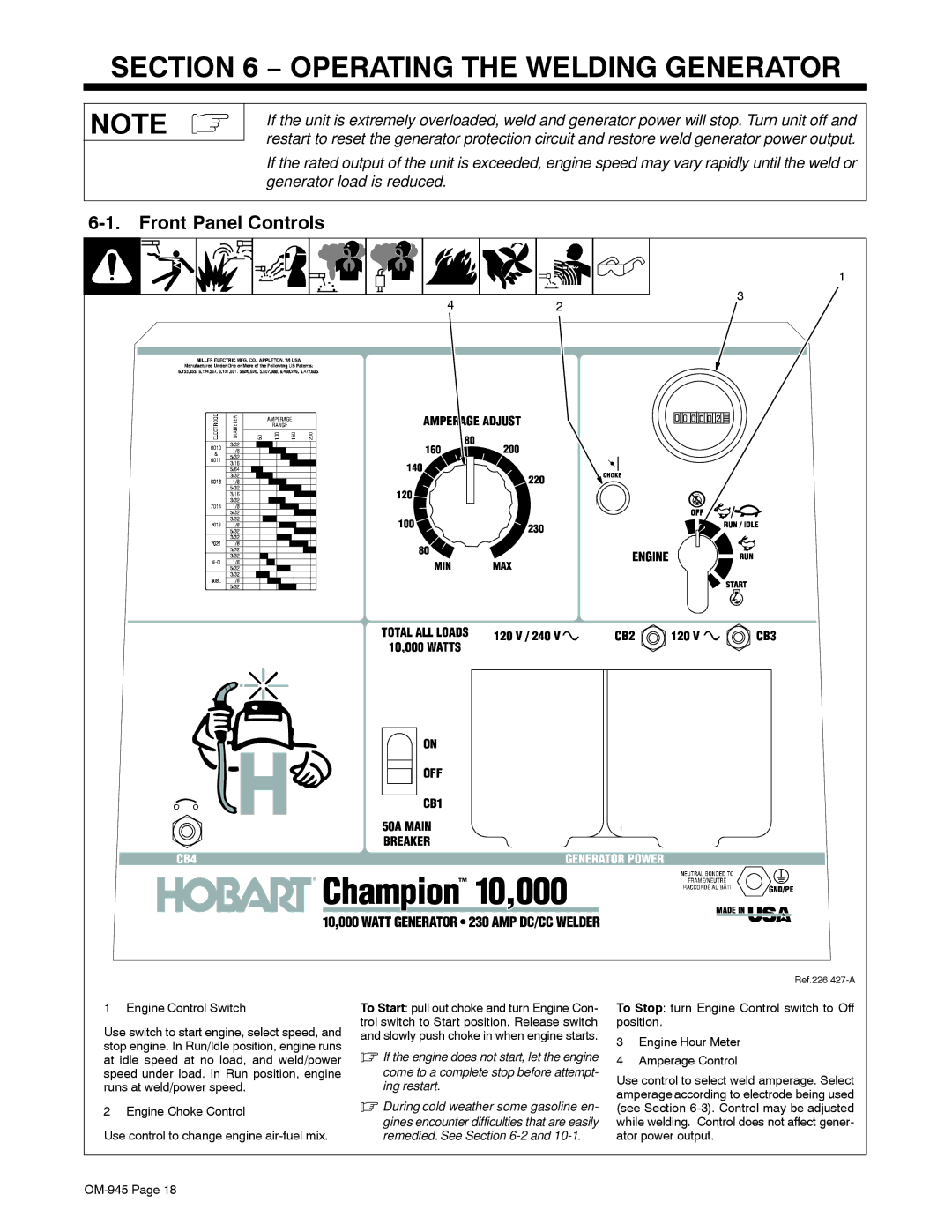

SECTION 6 − OPERATING THE WELDING GENERATOR

NOTE

If the unit is extremely overloaded, weld and generator power will stop. Turn unit off and restart to reset the generator protection circuit and restore weld generator power output.

If the rated output of the unit is exceeded, engine speed may vary rapidly until the weld or generator load is reduced.

|

|

|

|

| 1 |

4 | 2 | 3 |

|

1 Engine Control Switch

Use switch to start engine, select speed, and stop engine. In Run/Idle position, engine runs at idle speed at no load, and weld/power speed under load. In Run position, engine runs at weld/power speed.

2 Engine Choke Control

Use control to change engine

To Start: pull out choke and turn Engine Con- trol switch to Start position. Release switch and slowly push choke in when engine starts.

.If the engine does not start, let the engine

come to a complete stop before attempt- ing restart.

.During cold weather some gasoline en-

gines encounter difficulties that are easily remedied. See Section

Ref.226

To Stop: turn Engine Control switch to Off position.

3Engine Hour Meter

4Amperage Control

Use control to select weld amperage. Select amperage according to electrode being used (see Section