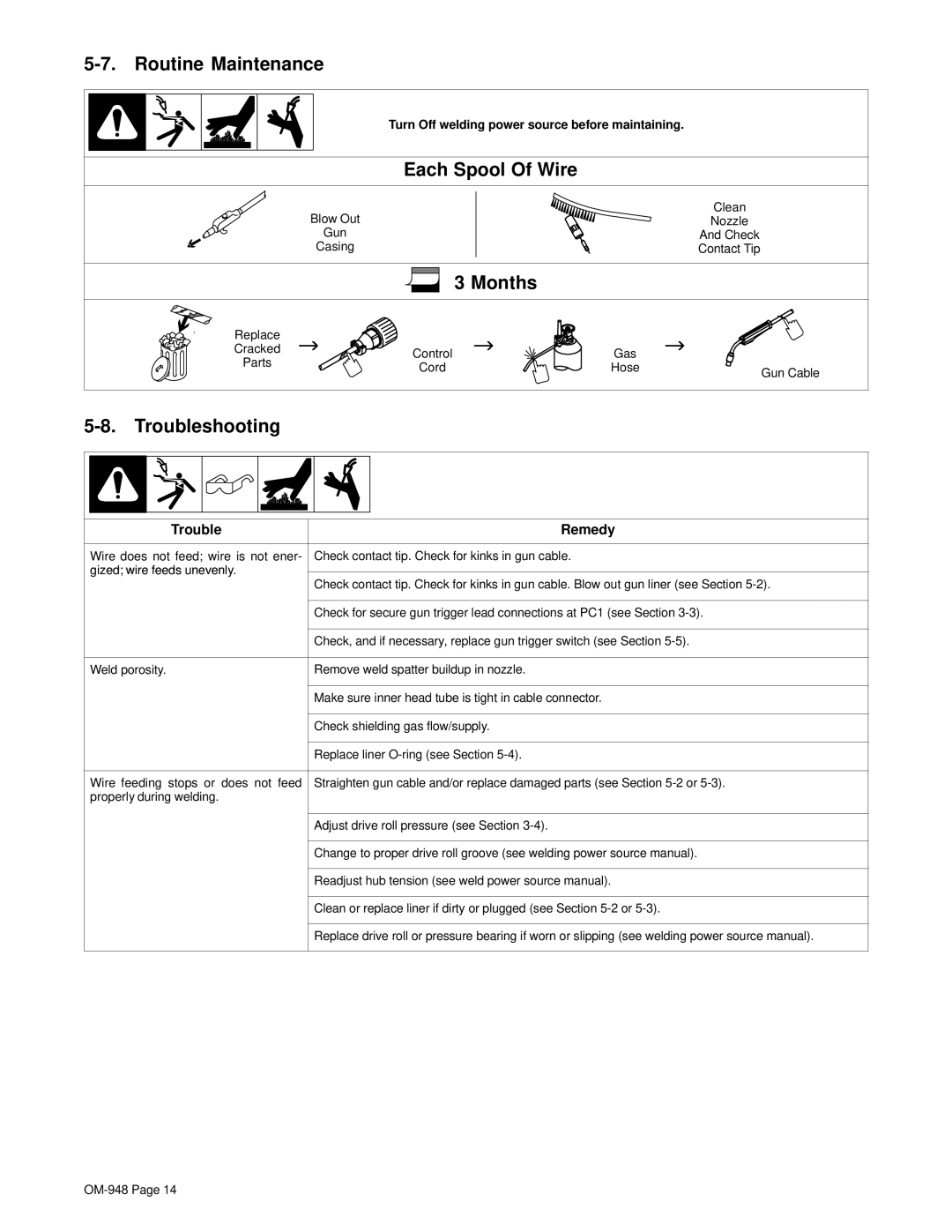

5-7. Routine Maintenance

| Y Turn Off welding power source before maintaining. |

| ||

| Each Spool Of Wire |

|

| |

| Blow Out |

| Clean | |

|

| Nozzle | ||

| Gun |

| And Check | |

| Casing |

| Contact Tip | |

| 3 Months |

|

| |

Replace |

|

|

| |

Cracked | Control | Gas |

| |

Parts |

| |||

Cord | Hose | Gun Cable | ||

| ||||

|

|

| ||

5-8. Troubleshooting

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Trouble |

|

| Remedy | ||

|

|

|

|

|

|

|

|

| Wire does not feed; wire is not ener- |

| Check contact tip. Check for kinks in gun cable. | ||||

| gized; wire feeds unevenly. |

|

|

| |||

| Check contact tip. Check for kinks in gun cable. Blow out gun liner (see Section | ||||||

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Check for secure gun trigger lead connections at PC1 (see Section | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Check, and if necessary, replace gun trigger switch (see Section | |

|

|

|

|

|

|

|

|

| Weld porosity. |

| Remove weld spatter buildup in nozzle. | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Make sure inner head tube is tight in cable connector. | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Check shielding gas flow/supply. | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Replace liner | |

|

|

|

|

|

|

|

|

| Wire feeding stops or does not feed |

| Straighten gun cable and/or replace damaged parts (see Section | ||||

| properly during welding. |

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Adjust drive roll pressure (see Section | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Change to proper drive roll groove (see welding power source manual). | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Readjust hub tension (see weld power source manual). | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Clean or replace liner if dirty or plugged (see Section | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Replace drive roll or pressure bearing if worn or slipping (see welding power source manual). | |

|

|

|

|

|

|

|

|