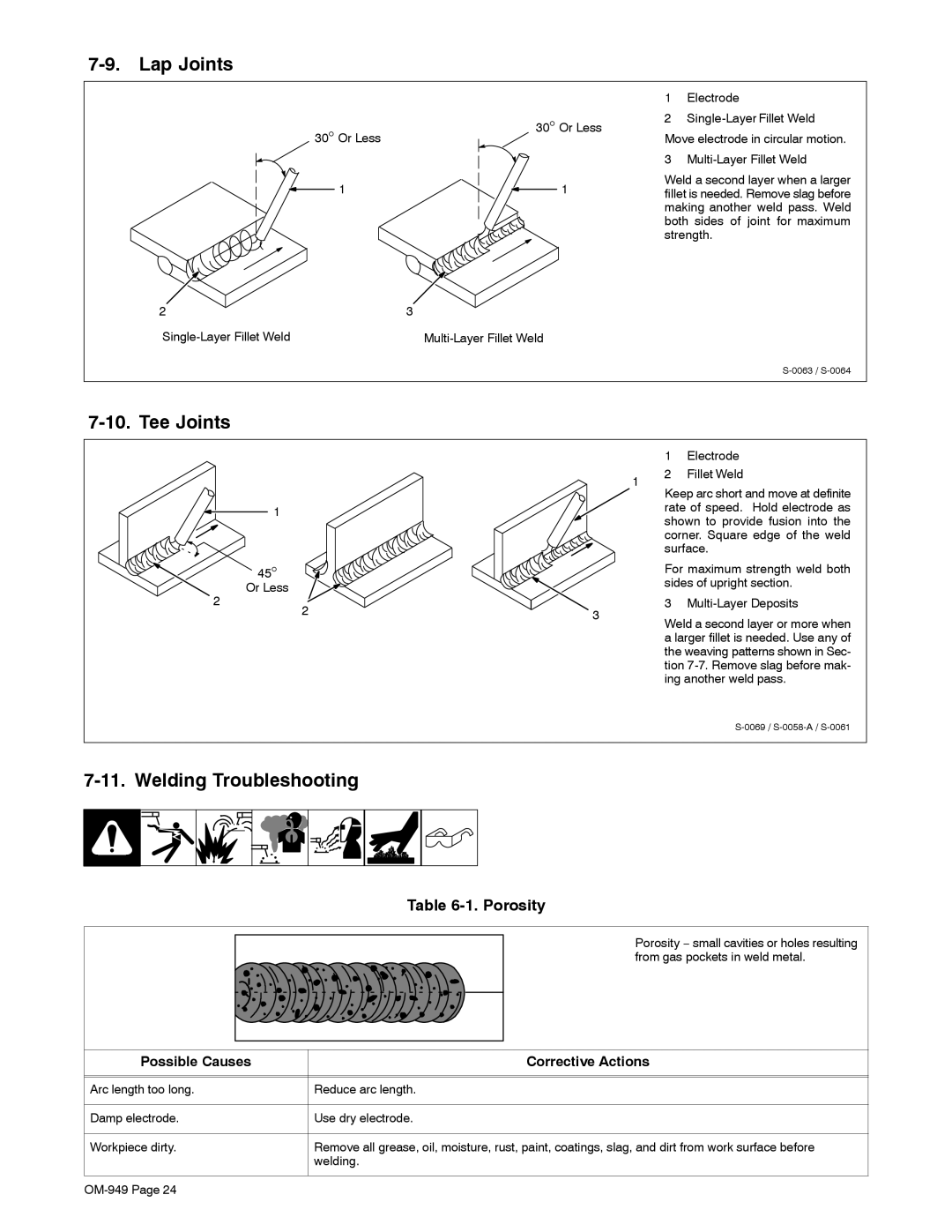

7-9. Lap Joints

30° Or Less | 30° Or Less |

| |

1 | 1 |

2 | 3 |

1Electrode

2

3

Weld a second layer when a larger fillet is needed. Remove slag before making another weld pass. Weld both sides of joint for maximum strength.

7-10. Tee Joints

1

45°

Or Less

2

2

1 Electrode

12 Fillet Weld

Keep arc short and move at definite rate of speed. Hold electrode as

| shown to provide fusion into the | |

| corner. Square edge of the weld | |

| surface. | |

| For maximum strength weld both | |

| sides of upright section. | |

3 | 3 | |

Weld a second layer or more when | ||

| ||

| a larger fillet is needed. Use any of | |

| the weaving patterns shown in Sec- | |

| tion | |

| ing another weld pass. | |

|

7-11. Welding Troubleshooting

Table 6-1. Porosity

Porosity − small cavities or holes resulting from gas pockets in weld metal.

Possible Causes | Corrective Actions |

|

|

|

|

Arc length too long. | Reduce arc length. |

|

|

Damp electrode. | Use dry electrode. |

|

|

Workpiece dirty. | Remove all grease, oil, moisture, rust, paint, coatings, slag, and dirt from work surface before |

| welding. |

|

|

|