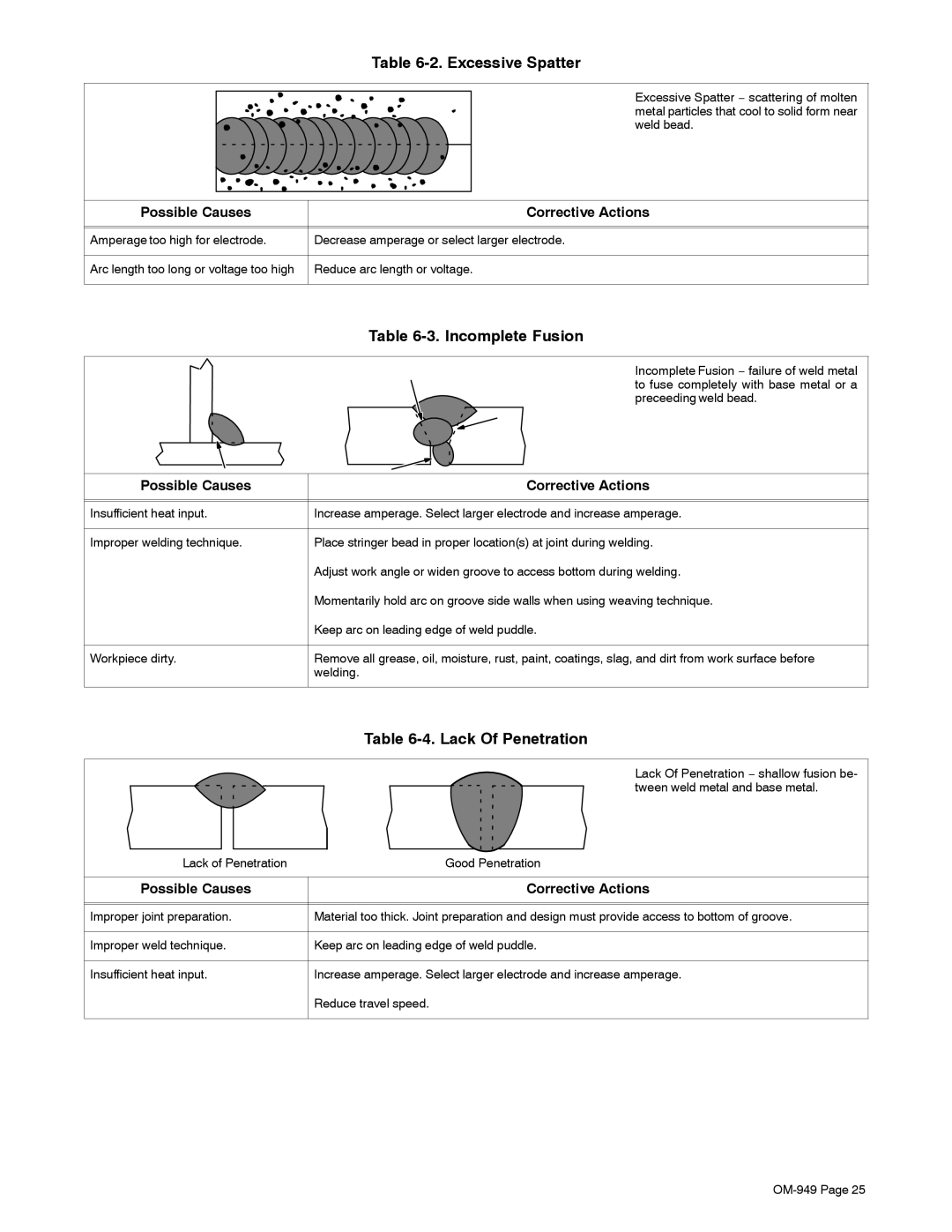

| Table |

| Excessive Spatter − scattering of molten |

| metal particles that cool to solid form near |

| weld bead. |

Possible Causes | Corrective Actions |

Amperage too high for electrode. | Decrease amperage or select larger electrode. |

Arc length too long or voltage too high | Reduce arc length or voltage. |

| Table |

| Incomplete Fusion − failure of weld metal |

| to fuse completely with base metal or a |

| preceeding weld bead. |

Possible Causes | Corrective Actions |

Insufficient heat input. | Increase amperage. Select larger electrode and increase amperage. |

Improper welding technique. | Place stringer bead in proper location(s) at joint during welding. |

| Adjust work angle or widen groove to access bottom during welding. |

| Momentarily hold arc on groove side walls when using weaving technique. |

| Keep arc on leading edge of weld puddle. |

Workpiece dirty. | Remove all grease, oil, moisture, rust, paint, coatings, slag, and dirt from work surface before |

| welding. |

| Table |

| Lack Of Penetration − shallow fusion be- |

| tween weld metal and base metal. |

Lack of Penetration | Good Penetration |

|

|

Possible Causes | Corrective Actions |

|

|

|

|

Improper joint preparation. | Material too thick. Joint preparation and design must provide access to bottom of groove. |

|

|

Improper weld technique. | Keep arc on leading edge of weld puddle. |

|

|

Insufficient heat input. | Increase amperage. Select larger electrode and increase amperage. |

| Reduce travel speed. |

|

|