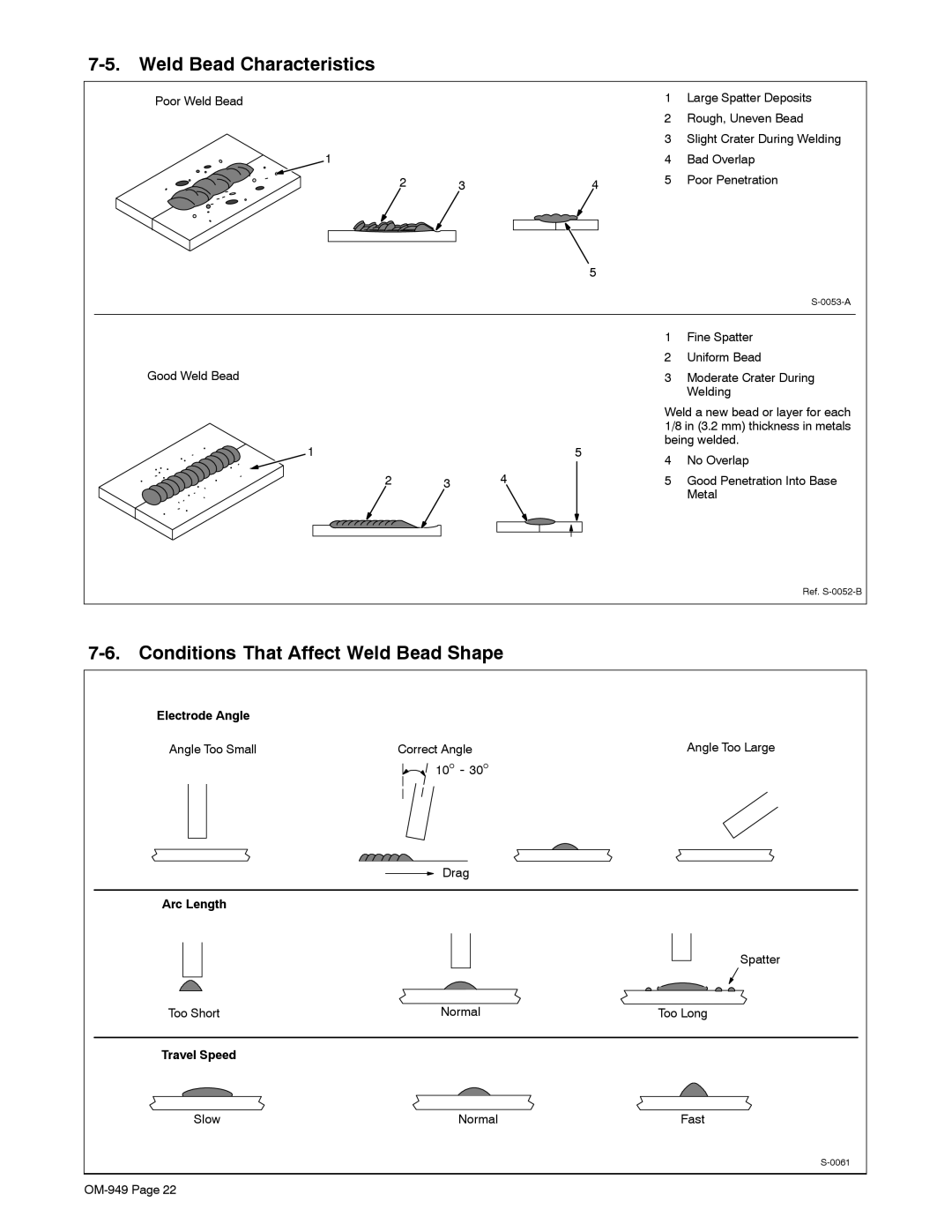

7-5. Weld Bead Characteristics

Poor Weld Bead |

|

| 1 | Large Spatter Deposits |

|

|

| 2 | Rough, Uneven Bead |

|

|

| 3 | Slight Crater During Welding |

1 |

|

| 4 | Bad Overlap |

2 | 3 | 4 | 5 | Poor Penetration |

|

|

|

| 5 |

|

|

|

|

|

| |

|

|

|

| 1 | Fine Spatter |

|

|

|

| 2 | Uniform Bead |

Good Weld Bead |

|

|

| 3 | Moderate Crater During |

|

|

|

|

| Welding |

|

|

|

| Weld a new bead or layer for each | |

|

|

|

| 1/8 in (3.2 mm) thickness in metals | |

1 |

|

| 5 | being welded. | |

|

| 4 | No Overlap | ||

|

|

|

| ||

2 | 3 | 4 |

| 5 | Good Penetration Into Base |

|

|

|

|

| Metal |

Ref.

7-6. Conditions That Affect Weld Bead Shape

Electrode Angle |

|

|

Angle Too Small | Correct Angle | Angle Too Large |

| 10° - 30° |

|

| Drag |

|

Arc Length

Spatter

Too Short | Normal | Too Long |

Travel Speed

Slow | Normal | Fast |