CONDENSER

Important: Always switch off and remove the plug from the electricity supply before cleaning the condenser.

To maintain the efficiency of the dryer regularly check that the condenser is clean.

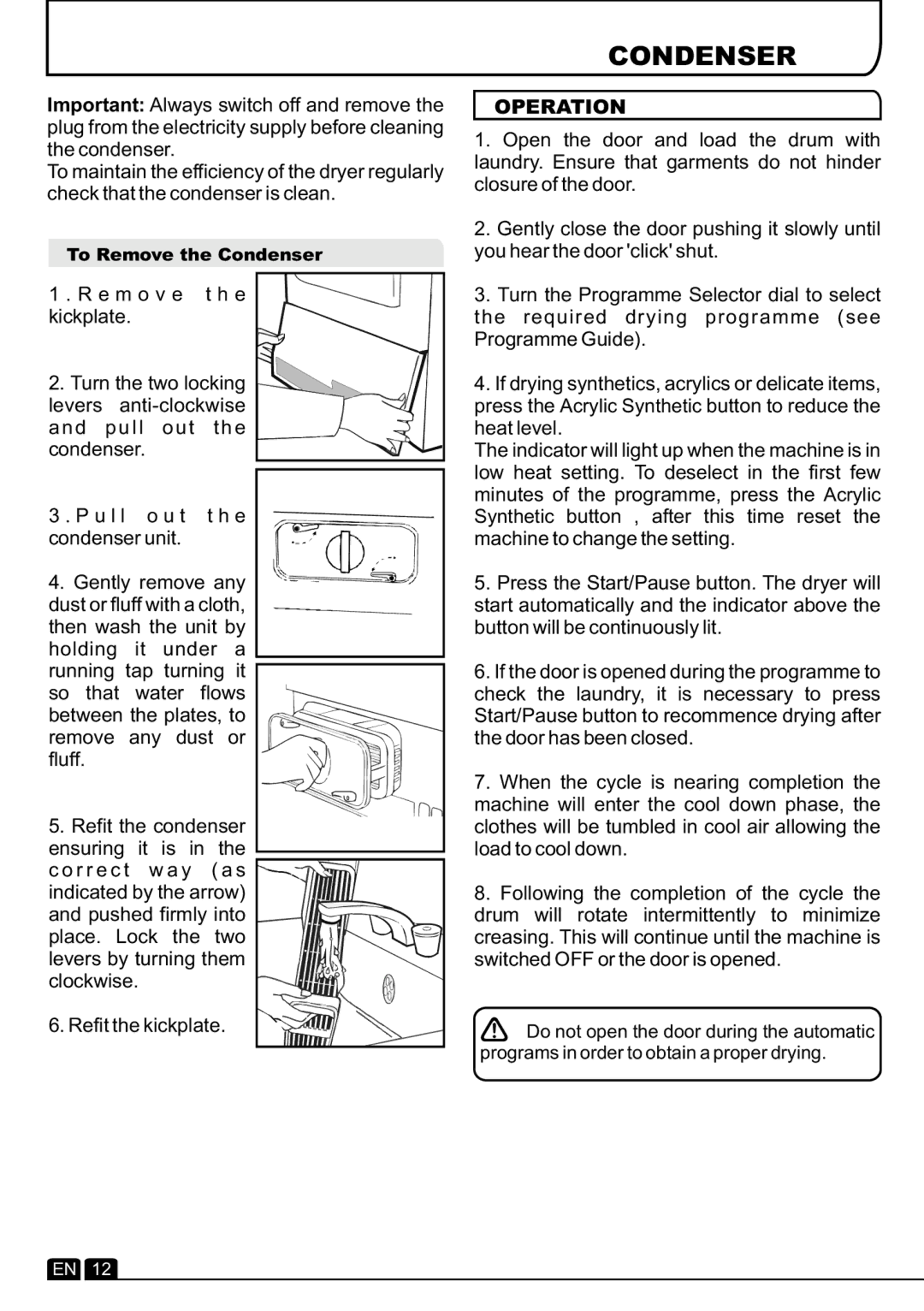

To Remove the Condenser

1 . R e m o v e t h e | |

kickplate. | |

2. Turn the two locking | |

levers | |

a n d p u l l o u t t h e | |

condenser. | |

3 . P u l l o u t t h e | |

condenser unit. | |

4. Gently remove any dust or fluff with a cloth, then wash the unit by holding it under a running tap turning it so that water flows between the plates, to remove any dust or fluff.

5. Refit the condenser ensuring it is in the c o r r e c t w a y ( a s indicated by the arrow) and pushed firmly into place. Lock the two levers by turning them clockwise.

6. Refit the kickplate.

OPERATION

1.Open the door and load the drum with laundry. Ensure that garments do not hinder closure of the door.

2.Gently close the door pushing it slowly until you hear the door 'click' shut.

3.Turn the Programme Selector dial to select the required drying programme (see Programme Guide).

4.If drying synthetics, acrylics or delicate items, press the Acrylic Synthetic button to reduce the heat level.

The indicator will light up when the machine is in low heat setting. To deselect in the first few minutes of the programme, press the Acrylic Synthetic button , after this time reset the machine to change the setting.

5.Press the Start/Pause button. The dryer will start automatically and the indicator above the button will be continuously lit.

6.If the door is opened during the programme to check the laundry, it is necessary to press Start/Pause button to recommence drying after the door has been closed.

7.When the cycle is nearing completion the machine will enter the cool down phase, the clothes will be tumbled in cool air allowing the load to cool down.

8.Following the completion of the cycle the drum will rotate intermittently to minimize creasing. This will continue until the machine is switched OFF or the door is opened.

![]() Do not open the door during the automatic programs in order to obtain a proper drying.

Do not open the door during the automatic programs in order to obtain a proper drying.

EN 12