1. Upper Bearing Wear Check

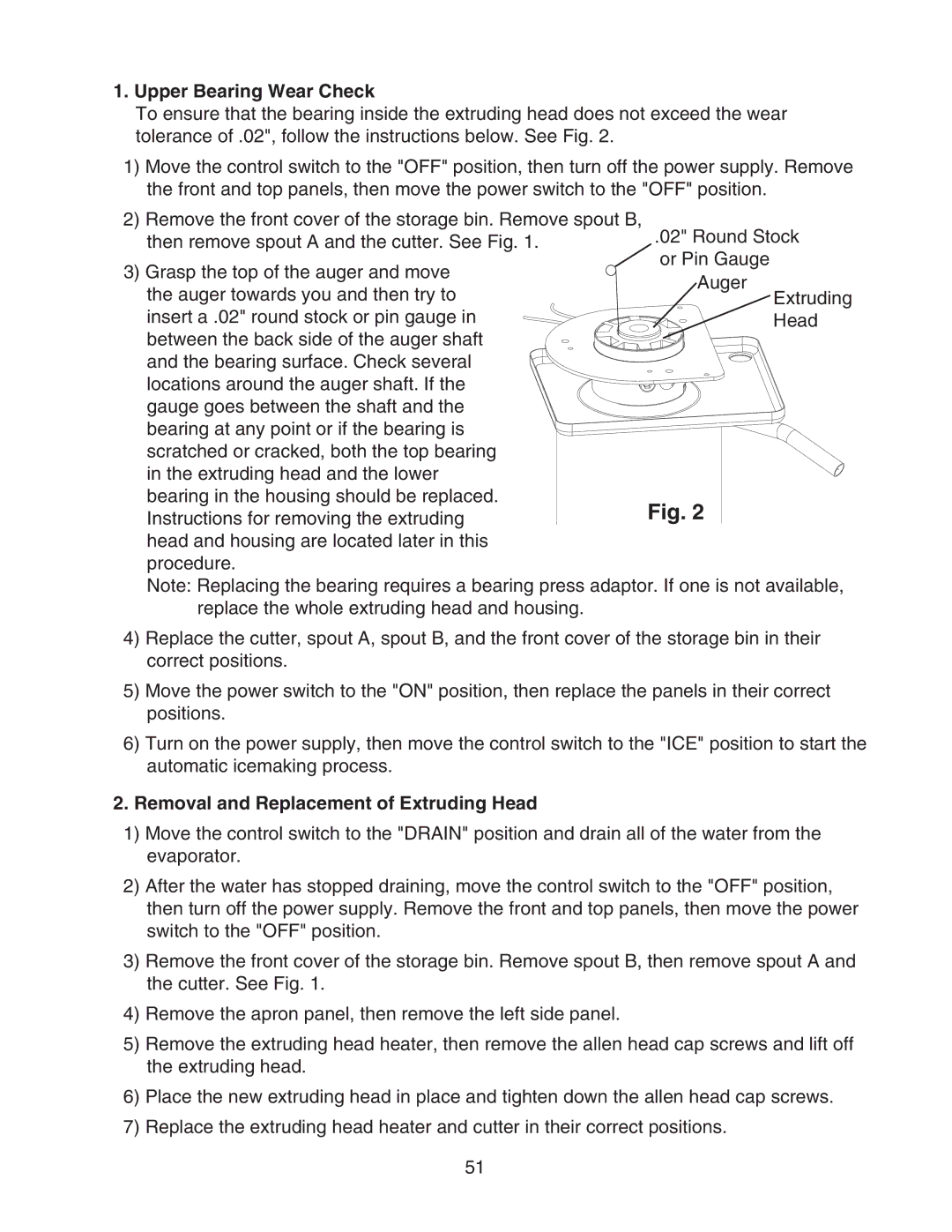

To ensure that the bearing inside the extruding head does not exceed the wear tolerance of .02", follow the instructions below. See Fig. 2.

1) Move the control switch to the "OFF" position, then turn off the power supply. Remove the front and top panels, then move the power switch to the "OFF" position.

2) Remove the front cover of the storage bin. Remove spout B, | .02" Round Stock | |

then remove spout A and the cutter. See Fig. 1. | ||

3) Grasp the top of the auger and move | or Pin Gauge | |

Auger | ||

the auger towards you and then try to | ||

Extruding | ||

insert a .02" round stock or pin gauge in | Head | |

between the back side of the auger shaft |

| |

and the bearing surface. Check several |

| |

locations around the auger shaft. If the |

| |

gauge goes between the shaft and the |

| |

bearing at any point or if the bearing is |

| |

scratched or cracked, both the top bearing |

| |

in the extruding head and the lower |

| |

bearing in the housing should be replaced. | Fig. 2 | |

Instructions for removing the extruding | ||

head and housing are located later in this |

| |

procedure. |

|

Note: Replacing the bearing requires a bearing press adaptor. If one is not available, replace the whole extruding head and housing.

4)Replace the cutter, spout A, spout B, and the front cover of the storage bin in their correct positions.

5)Move the power switch to the "ON" position, then replace the panels in their correct positions.

6)Turn on the power supply, then move the control switch to the "ICE" position to start the automatic icemaking process.

2.Removal and Replacement of Extruding Head

1)Move the control switch to the "DRAIN" position and drain all of the water from the evaporator.

2)After the water has stopped draining, move the control switch to the "OFF" position, then turn off the power supply. Remove the front and top panels, then move the power switch to the "OFF" position.

3)Remove the front cover of the storage bin. Remove spout B, then remove spout A and the cutter. See Fig. 1.

4)Remove the apron panel, then remove the left side panel.

5)Remove the extruding head heater, then remove the allen head cap screws and lift off the extruding head.

6)Place the new extruding head in place and tighten down the allen head cap screws.

7)Replace the extruding head heater and cutter in their correct positions.

51