Installation

Installation

The Automatic XT spray guns were designed to produce the highest quality finish with today's fluids as well as the low V.O.C. (volatile organic compound) fluids of tomorrow.

This spray gun can spray most coatings or finishes cur- rently being used for automotive, industrial, aerospace, marine, wood, plastic and architectural applications, while easily operating from paint delivery systems, such as pressure pots or remote pumps for production line operation.

The air regulator must have a minimum air flow capacity of 30 scfm at 100 psi (0.7 MPa, 7 bar) air pressure.

Ventilate Spray Booth

Check and follow all National, State, and Local codes regarding air exhaust velocity requirements.

Check and follow all local safety and fire codes.

Non-circulating System

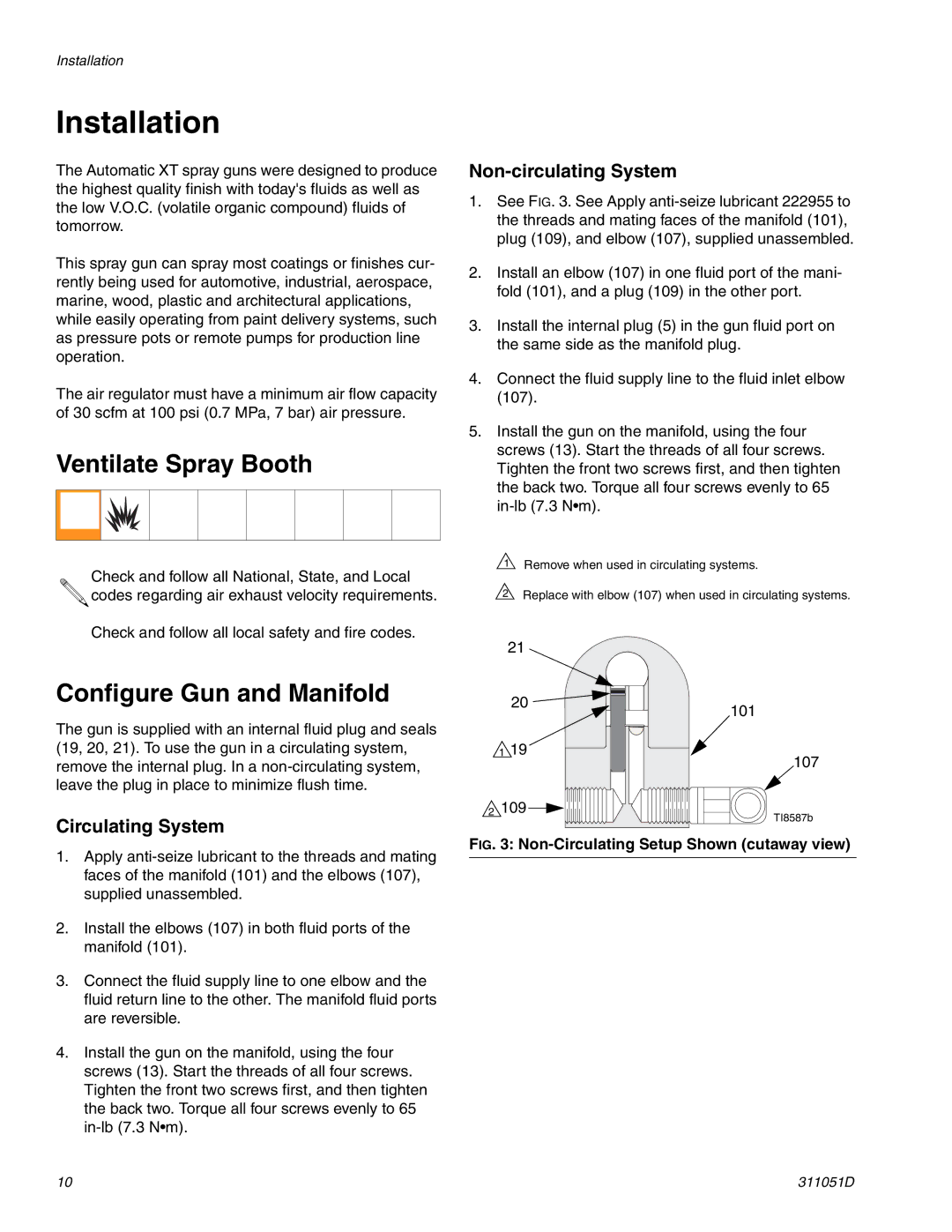

1.See FIG. 3. See Apply

2.Install an elbow (107) in one fluid port of the mani- fold (101), and a plug (109) in the other port.

3.Install the internal plug (5) in the gun fluid port on the same side as the manifold plug.

4.Connect the fluid supply line to the fluid inlet elbow (107).

5.Install the gun on the manifold, using the four screws (13). Start the threads of all four screws. Tighten the front two screws first, and then tighten the back two. Torque all four screws evenly to 65

1Remove when used in circulating systems.

2Replace with elbow (107) when used in circulating systems.

Configure Gun and Manifold

The gun is supplied with an internal fluid plug and seals (19, 20, 21). To use the gun in a circulating system, remove the internal plug. In a

Circulating System

21

20 ![]()

119

2109 ![]()

101

107

TI8587b

1.Apply

2.Install the elbows (107) in both fluid ports of the manifold (101).

3.Connect the fluid supply line to one elbow and the fluid return line to the other. The manifold fluid ports are reversible.

4.Install the gun on the manifold, using the four screws (13). Start the threads of all four screws. Tighten the front two screws first, and then tighten the back two. Torque all four screws evenly to 65

FIG. 3: Non-Circulating Setup Shown (cutaway view)

10 | 311051D |