Service

13. Remove all

(T). Check that the stems are solidly in place. If they are loose, replace the entire piston assembly (3).

14. Perform the following applicable step:

a.

1 2

11* 3

2 | 2 | 10* 3 |

16 8

25

23 1 2

24

17 3

5

5a9

36

TI8199a

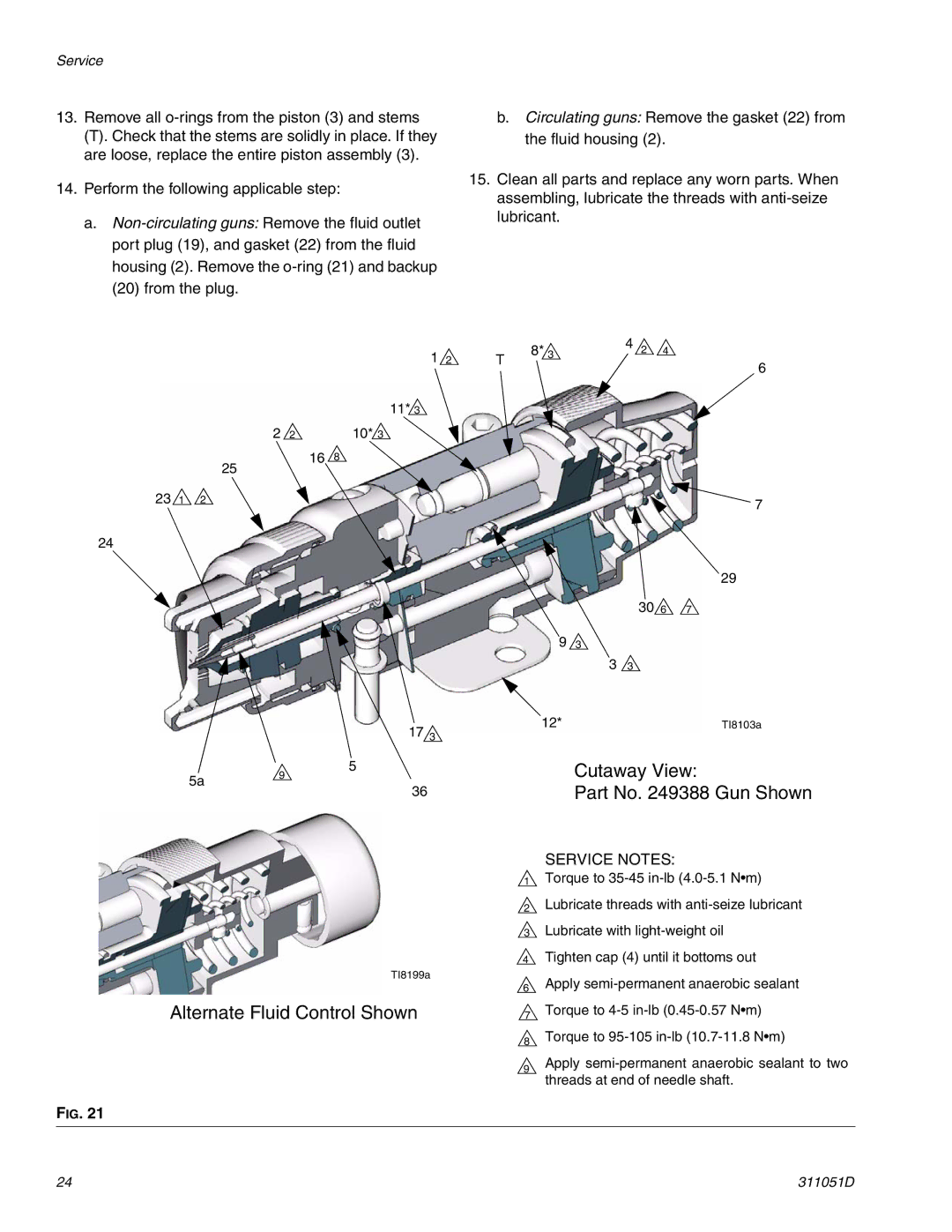

Alternate Fluid Control Shown

FIG. 21

b.Circulating guns: Remove the gasket (22) from the fluid housing (2).

15.Clean all parts and replace any worn parts. When assembling, lubricate the threads with

8* | 3 | 4 | 2 | 4 |

T |

|

|

| 6 |

|

|

|

|

7

29

30 6 7

93

33

12* | TI8103a |

Cutaway View:

Part No. 249388 Gun Shown

SERVICE NOTES:

1Torque to

2Lubricate threads with

3Lubricate with

4Tighten cap (4) until it bottoms out

6Apply

7Torque to

8Torque to

9Apply

24 | 311051D |