Drive Housing

Drive Housing

Removal

WARNING

Read Skin Injection Hazard, page 3; Burn Hazard, page 4

1.Relieve pressure; page 5.

2.Remove bearing housing. Refer to Bearing Housing and Connecting Rod, Removal, page 8.

CAUTION

Gallon counter sensor is connected to control board in pres- sure control. Pulling on the sensor wires could cause damage.

3.Premium sprayers: Remove two screws (108) and gallon counter sensor (39).

CAUTION

Thrust washers may stick to grease inside of drive housing. Do not lose or misplace.

4.Remove six screws (38).

5.Lightly tap around drive housing (33) to loosen drive housing. Pull drive housing straight off pinion housing. Be prepared to support combination gear (32) which may also come out.

Installation

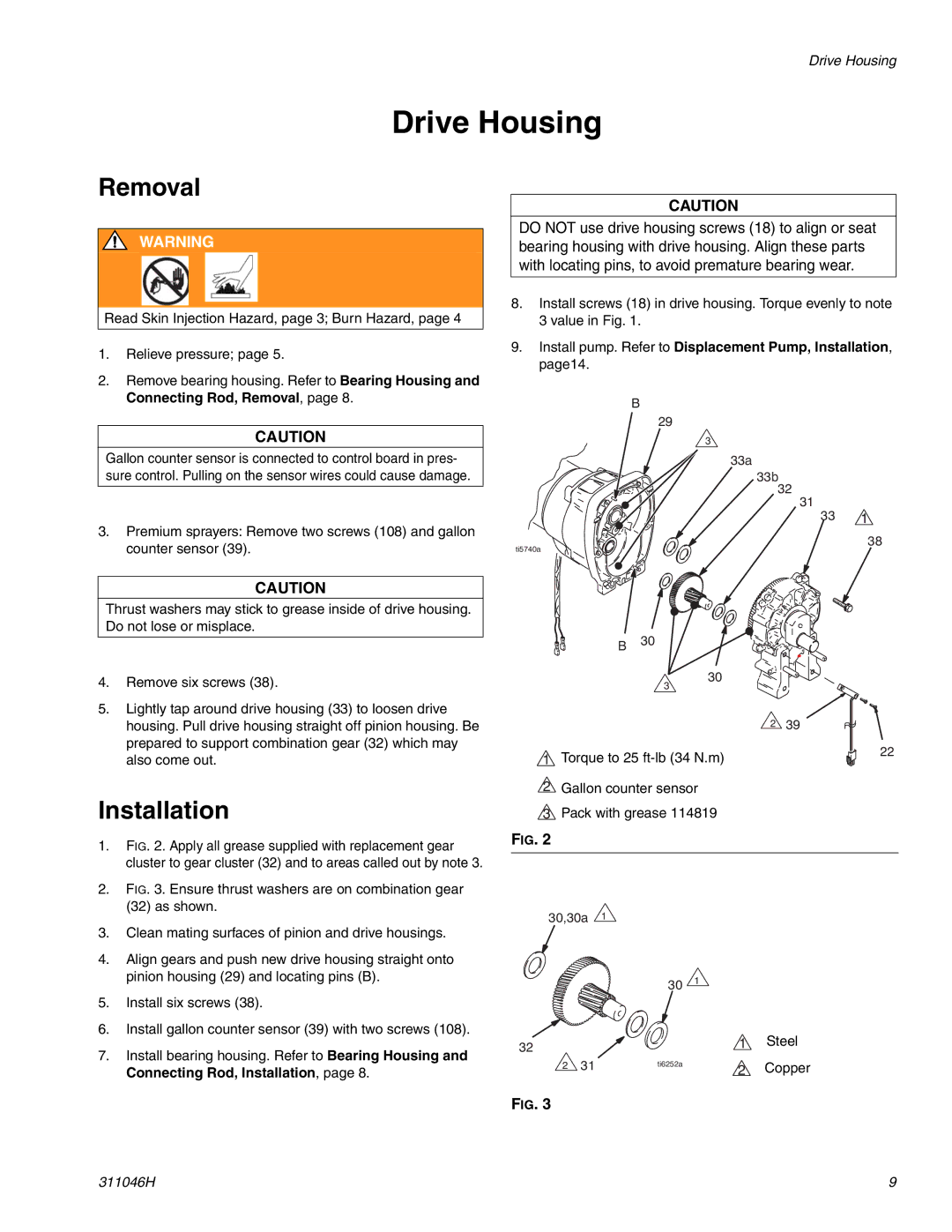

1.FIG. 2. Apply all grease supplied with replacement gear cluster to gear cluster (32) and to areas called out by note 3.

2.FIG. 3. Ensure thrust washers are on combination gear (32) as shown.

CAUTION

DO NOT use drive housing screws (18) to align or seat bearing housing with drive housing. Align these parts with locating pins, to avoid premature bearing wear.

8.Install screws (18) in drive housing. Torque evenly to note 3 value in Fig. 1.

9.Install pump. Refer to Displacement Pump, Installation, page14.

B

29

3

33a

33b

32

31

33 1

38

ti5740a

B30

30

3 |

|

2 | 39 |

1 Torque to 25 | 22 |

|

2Gallon counter sensor

3Pack with grease 114819

FIG. 2

30,30a 1

3.Clean mating surfaces of pinion and drive housings.

4.Align gears and push new drive housing straight onto

pinion housing (29) and locating pins (B). | 30 | 1 |

|

5.Install six screws (38).

6.Install gallon counter sensor (39) with two screws (108).

7. Install bearing housing. Refer to Bearing Housing and | 32 |

|

| 1 | Steel | |

2 | 31 | ti6252a | 2 | Copper | ||

Connecting Rod, Installation, page 8. | ||||||

|

|

|

FIG. 3

311046H | 9 |