13

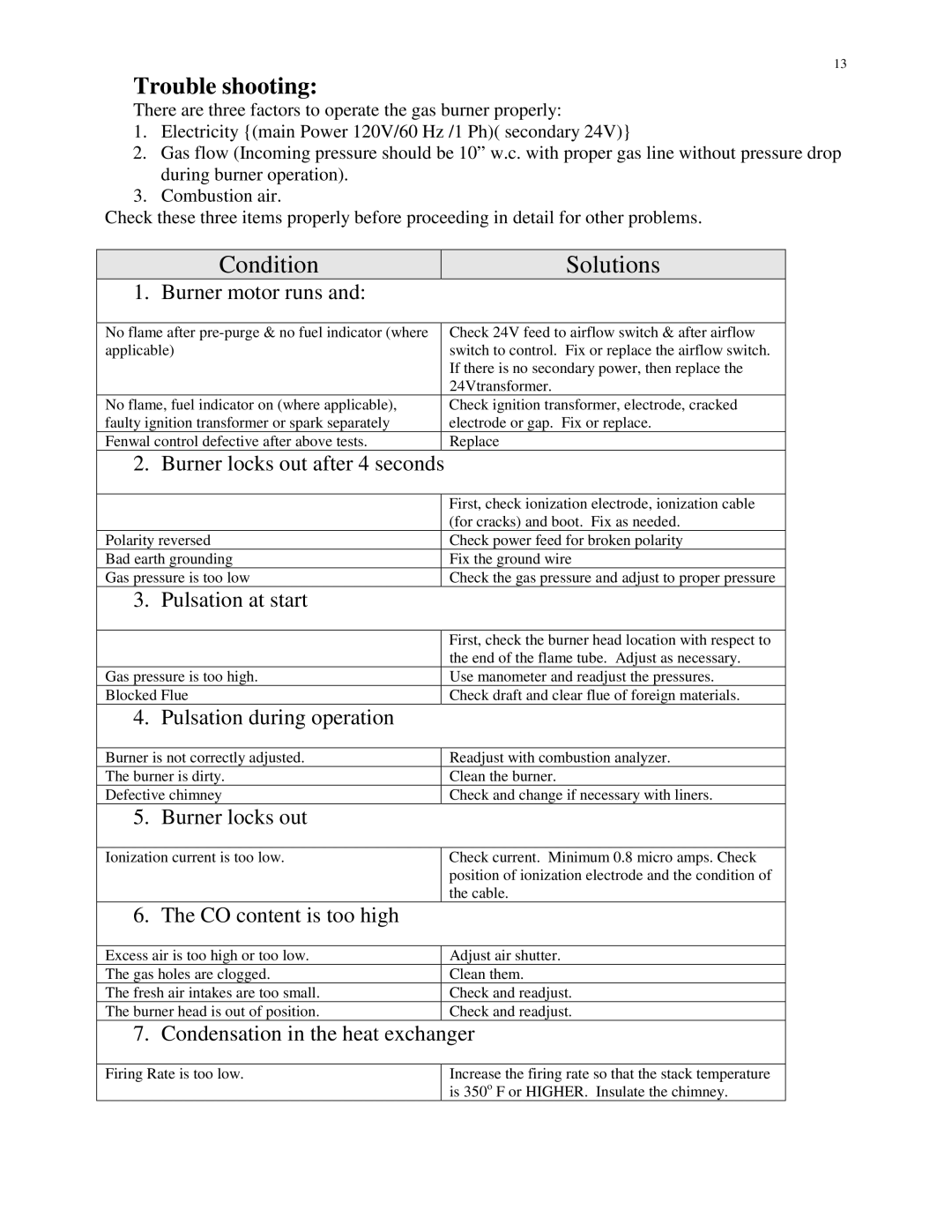

Trouble shooting:

There are three factors to operate the gas burner properly:

1.Electricity {(main Power 120V/60 Hz /1 Ph)( secondary 24V)}

2.Gas flow (Incoming pressure should be 10” w.c. with proper gas line without pressure drop during burner operation).

3.Combustion air.

Check these three items properly before proceeding in detail for other problems.

Condition

1. Burner motor runs and:

Solutions

No flame after | Check 24V feed to airflow switch & after airflow |

applicable) | switch to control. Fix or replace the airflow switch. |

| If there is no secondary power, then replace the |

| 24Vtransformer. |

No flame, fuel indicator on (where applicable), | Check ignition transformer, electrode, cracked |

faulty ignition transformer or spark separately | electrode or gap. Fix or replace. |

Fenwal control defective after above tests. | Replace |

2. Burner locks out after 4 seconds |

|

|

|

| First, check ionization electrode, ionization cable |

| (for cracks) and boot. Fix as needed. |

Polarity reversed | Check power feed for broken polarity |

Bad earth grounding | Fix the ground wire |

Gas pressure is too low | Check the gas pressure and adjust to proper pressure |

3. Pulsation at start |

|

|

|

| First, check the burner head location with respect to |

| the end of the flame tube. Adjust as necessary. |

Gas pressure is too high. | Use manometer and readjust the pressures. |

Blocked Flue | Check draft and clear flue of foreign materials. |

4. Pulsation during operation |

|

|

|

Burner is not correctly adjusted. | Readjust with combustion analyzer. |

The burner is dirty. | Clean the burner. |

Defective chimney | Check and change if necessary with liners. |

5. Burner locks out |

|

Ionization current is too low.

6. The CO content is too high

Check current. Minimum 0.8 micro amps. Check position of ionization electrode and the condition of the cable.

Excess air is too high or too low. | Adjust air shutter. |

The gas holes are clogged. | Clean them. |

The fresh air intakes are too small. | Check and readjust. |

The burner head is out of position. | Check and readjust. |

7. Condensation in the heat exchanger

Firing Rate is too low.

Increase the firing rate so that the stack temperature is 350o F or HIGHER. Insulate the chimney.