3

CONVERTING OIL TO GAS

Before attempting the gas conversion, check to insure the heating system is properly sized for the total heating demand and the entire system is in good operating condition, including the fire chamber and flue passages. It is important to allow adequate clearance around the appliance for servicing and proper operation of the burner.

CONVERTING COAL TO GAS

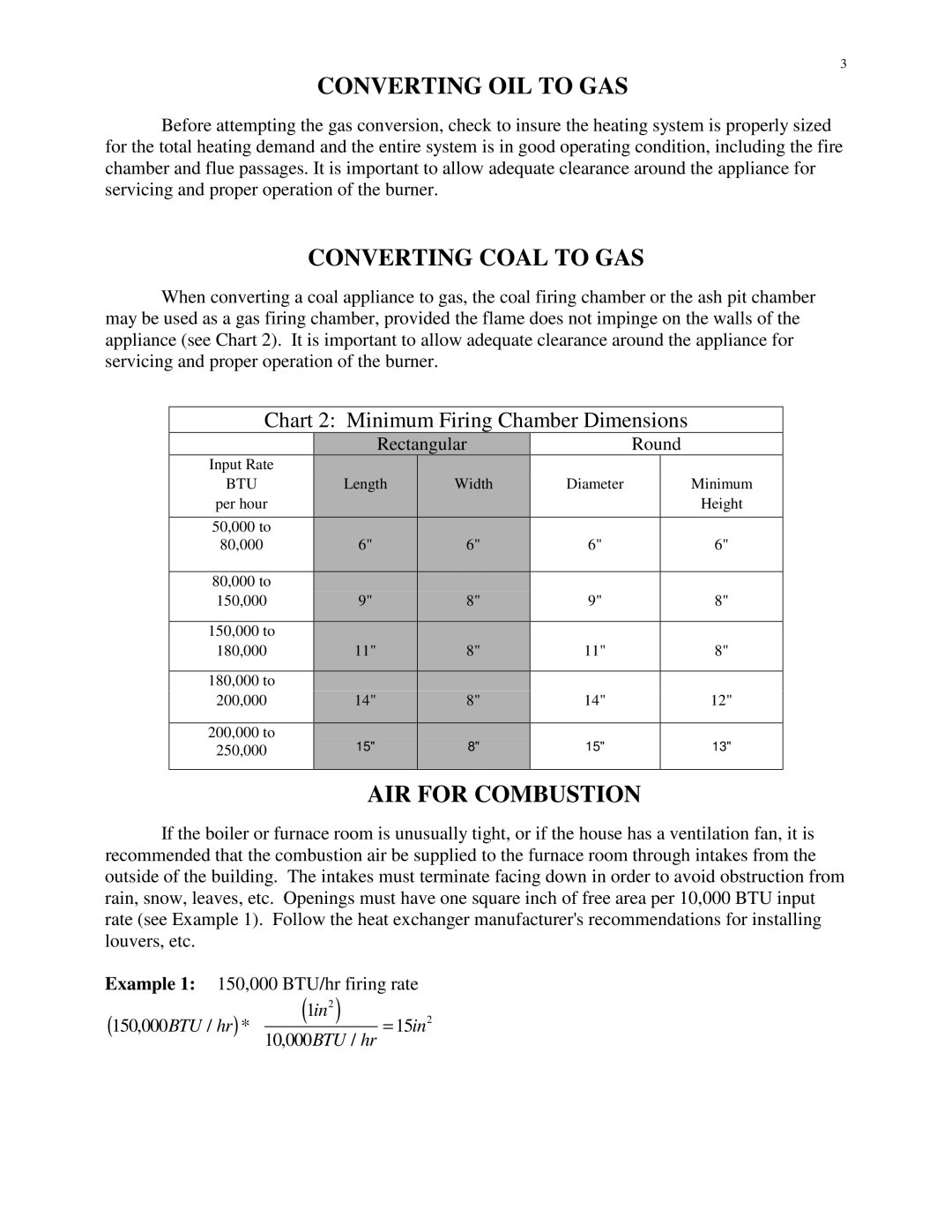

When converting a coal appliance to gas, the coal firing chamber or the ash pit chamber may be used as a gas firing chamber, provided the flame does not impinge on the walls of the appliance (see Chart 2). It is important to allow adequate clearance around the appliance for servicing and proper operation of the burner.

Chart 2: Minimum Firing Chamber Dimensions

Rectangular

Round

Input Rate |

|

|

|

| |

BTU | Length | Width | Diameter | Minimum | |

per hour |

|

|

| Height | |

50,000 to |

|

|

|

| |

80,000 | 6" | 6" | 6" | 6" | |

|

|

|

|

| |

80,000 to |

|

|

|

| |

150,000 | 9" | 8" | 9" | 8" | |

|

|

|

|

| |

150,000 to |

|

|

|

| |

180,000 | 11" | 8" | 11" | 8" | |

|

|

|

|

| |

180,000 to |

|

|

|

| |

200,000 | 14" | 8" | 14" | 12" | |

|

|

|

|

| |

200,000 to | 15" | 8" | 15" | 13" | |

250,000 | |||||

|

| ||||

|

|

|

|

|

AIR FOR COMBUSTION

If the boiler or furnace room is unusually tight, or if the house has a ventilation fan, it is recommended that the combustion air be supplied to the furnace room through intakes from the outside of the building. The intakes must terminate facing down in order to avoid obstruction from rain, snow, leaves, etc. Openings must have one square inch of free area per 10,000 BTU input rate (see Example 1). Follow the heat exchanger manufacturer©s recommendations for installing louvers, etc.

Example 1: 150,000 BTU/hr firing rate

(150,000BTU / hr) * | (1in2 ) | = 15in2 | |

10,000BTU / hr | |||

|

|