MAINTENANCE

Carburettor

Your Husqvarna product has been designed and manufac- tured to specifications that reduce harmful emissions. After your unit has been run

!WARNING!

The complete clutch cover and gear must be fitted before the machine is started, otherwise the clutch may come loose and cause injury.

Basic setting

•The carburettor is set to its basic setting when test run at the factory. The basic setting is richer than the optimal setting and should be kept during the machine’s first working hours. Thereafter the carburettor should be finely adjusted. Fine adjustment should be carried out by a skilled technician.

NOTE! If the cutting attachment rotates/moves while the engine is idling the

Recommended idling speed is 2 700 rpm. Recommended max. speed: See “technical data”.

WARNING! |

! If the idling speed cannot be adjusted so |

that the cutting attachment stops, |

contact your service workshop. Do not |

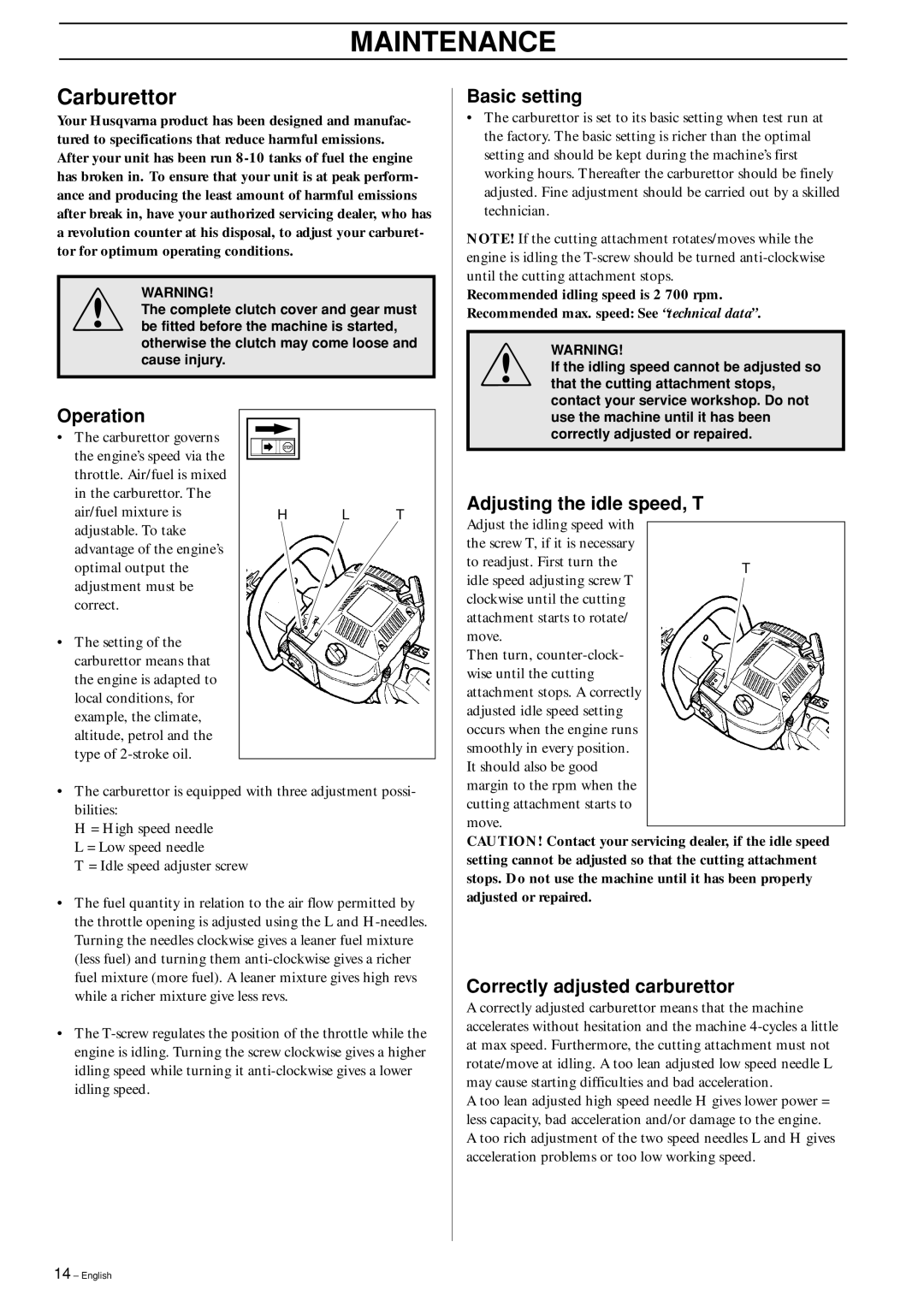

Operation

•The carburettor governs the engine’s speed via the throttle. Air/fuel is mixed in the carburettor. The air/fuel mixture is adjustable. To take advantage of the engine’s optimal output the adjustment must be correct.

•The setting of the carburettor means that the engine is adapted to local conditions, for example, the climate, altitude, petrol and the type of

H | L | T |

use the machine until it has been |

correctly adjusted or repaired. |

Adjusting the idle speed, T |

| ||

Adjust the idling speed with |

|

| |

|

| ||

the screw T, if it is necessary |

| ||

to readjust. First turn the | T | ||

idle speed adjusting screw T | |||

| |||

clockwise until the cutting |

| ||

attachment starts to rotate/ |

| ||

move. |

| ||

Then turn, |

| ||

wise until the cutting |

| ||

attachment stops. A correctly |

| ||

adjusted idle speed setting |

| ||

occurs when the engine runs |

| ||

smoothly in every position. |

| ||

It should also be good |

| ||

margin to the rpm when the |

| ||

•The carburettor is equipped with three adjustment possi- bilities:

H = High speed needle L = Low speed needle

T = Idle speed adjuster screw

•The fuel quantity in relation to the air flow permitted by the throttle opening is adjusted using the L and

•The

cutting attachment starts to |

move. |

CAUTION! Contact your servicing dealer, if the idle speed setting cannot be adjusted so that the cutting attachment stops. Do not use the machine until it has been properly adjusted or repaired.

Correctly adjusted carburettor

A correctly adjusted carburettor means that the machine accelerates without hesitation and the machine

A too lean adjusted high speed needle H gives lower power = less capacity, bad acceleration and/or damage to the engine. A too rich adjustment of the two speed needles L and H gives acceleration problems or too low working speed.

14 – English