261 specifications

The Husqvarna 261 is a robust and versatile chainsaw designed for professional use, particularly appealing to forestry workers, and those engaged in tree care and maintenance. This model stands out for its balance of power and lightweight design, making it an excellent choice for those who need a reliable tool for extended use.One of the standout features of the Husqvarna 261 is its efficient 50.1cc engine, which delivers impressive cutting performance while maintaining low fuel consumption. This model incorporates a X-Torq engine technology that reduces emissions, making it an environmentally friendly option that complies with stringent regulations. Users can benefit from increased torque over a wide RPM range, resulting in optimal cutting performance even in tough conditions.

Another significant characteristic of the Husqvarna 261 is its LowVib technology. This system effectively reduces vibrations, allowing operators to work longer with minimal fatigue. The ergonomic design of the chainsaw, combined with a comfortable grip, further enhances user control and reduces strain during operation.

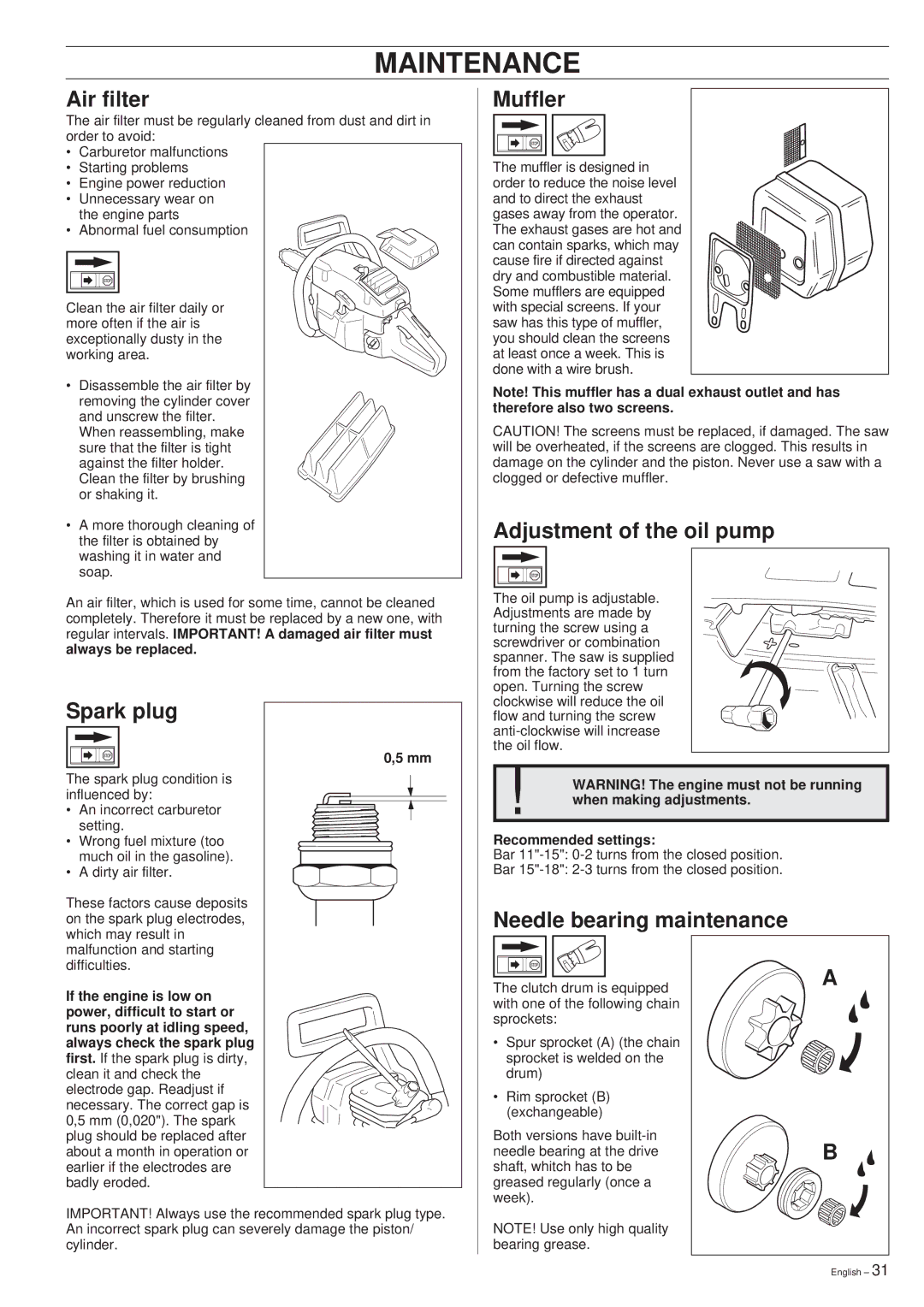

Safety is a priority in the design of the Husqvarna 261. It is equipped with an inertia chain brake that stops the chain immediately in case of kickback, protecting the user from potential injury. The chainsaw also features an adjustable oil pump, allowing for precise lubrication of the chain according to the user's specific needs, thus prolonging the life of both the chain and the guide bar.

The air filtration system is another key feature that sets the Husqvarna 261 apart. The innovative design includes a three-piece air filter that effectively keeps dust and debris from entering the engine, ensuring long-lasting performance and reduced maintenance. Furthermore, the quick-release cover allows for easy access to the air filter and spark plug, simplifying routine maintenance tasks.

Overall, the Husqvarna 261 combines advanced technology with user-friendly features, making it a standout choice for professionals who require reliability and performance. Its robust design, coupled with safety features and efficient engine technology, ensures that it can handle the demanding tasks across various cutting applications, establishing it as a preferred tool in the chainsaw market. Whether for logging, landscaping, or general tree work, the Husqvarna 261 is engineered to meet and exceed the expectations of discerning users.