| ASSEMBLY |

|

Assembling the loop handlebar | Assembling the blade |

|

• Position the handle on the | Fit the blade as follows: |

|

shaft. Note that the handle | 1. Fit the drive disc (A) on the |

|

must be mounted below the |

| |

arrow on the shaft. | outgoing shaft. Make sure |

|

| that the edge that fits in |

|

• Fit the bolt, securing plate | the hole of the blade is |

|

and wing nut as shown in the | facing outward. |

|

diagram. | 2. Block the blade rotation by |

|

|

| |

• Tighten the wing nut. | inserting locking pin in the |

|

hole behind the blade |

| |

|

| |

| guard engaging it in the |

|

| corresponding hole in the |

|

| drive disc. |

|

| 3. Fit the blade (B) on the |

|

| drive disc. |

|

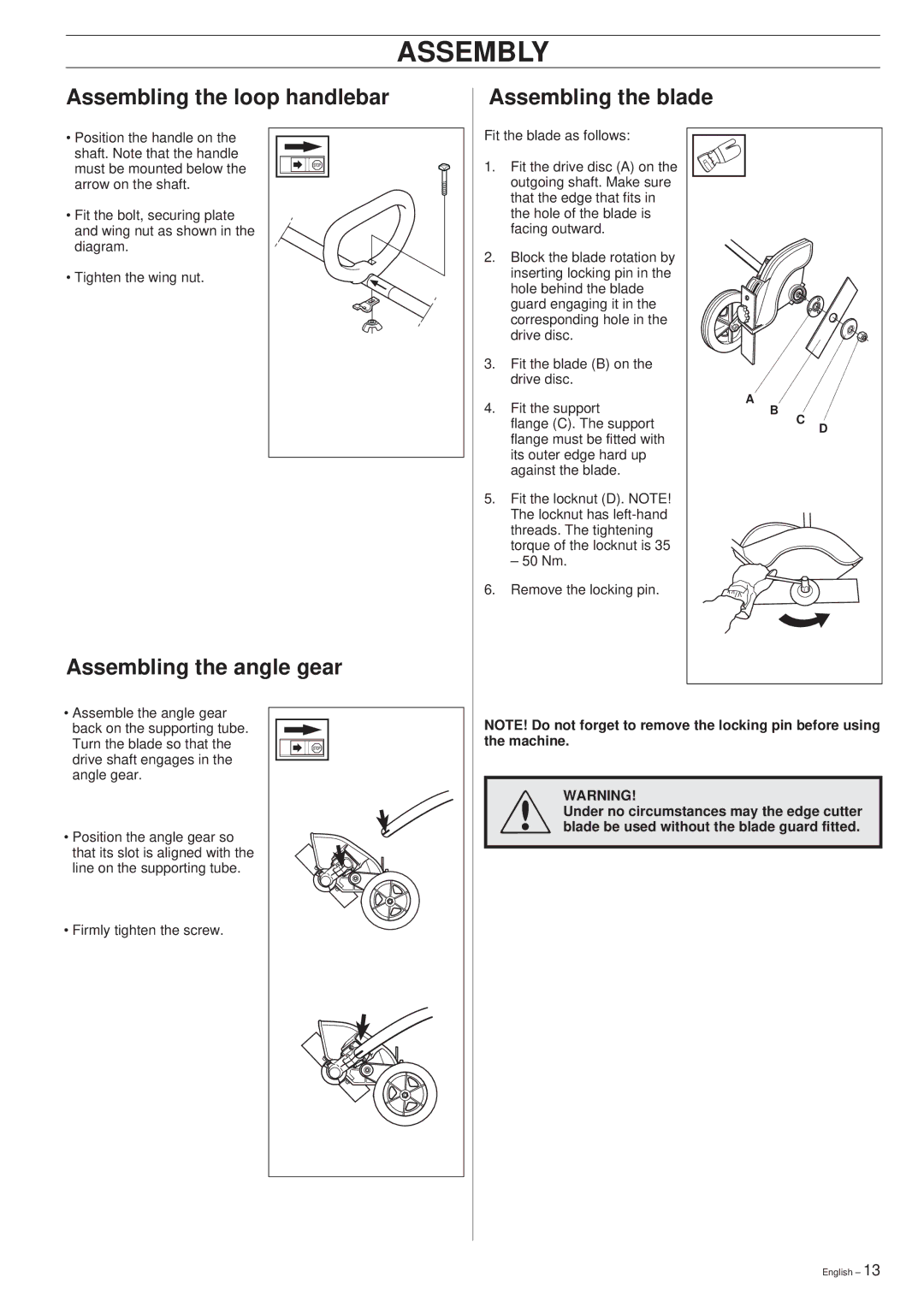

| 4. Fit the support | A |

| B | |

| flange (C). The support | C |

| flange must be fitted with | D |

|

| |

| its outer edge hard up |

|

| against the blade. |

|

| 5. Fit the locknut (D). NOTE! |

|

| The locknut has |

|

| threads. The tightening |

|

| torque of the locknut is 35 |

|

| – 50 Nm. |

|

| 6. Remove the locking pin. |

|

Assembling the angle gear |

|

|

• Assemble the angle gear | NOTE! Do not forget to remove the locking pin before using |

back on the supporting tube. | |

Turn the blade so that the | the machine. |

drive shaft engages in the |

|

angle gear. |

|

| WARNING! |

| Under no circumstances may the edge cutter |

• Position the angle gear so | ! blade be used without the blade guard fitted. |

| |

that its slot is aligned with the |

|

line on the supporting tube. |

|

• Firmly tighten the screw.

English – 13