MAINTENANCE

General

IMPORTANT! Inspection and/or maintenance should be carried out with the motor switched off and the plug disconnected.

The lifetime of your machine can be extended considerably if it is used, cared for and maintained in the proper manner.

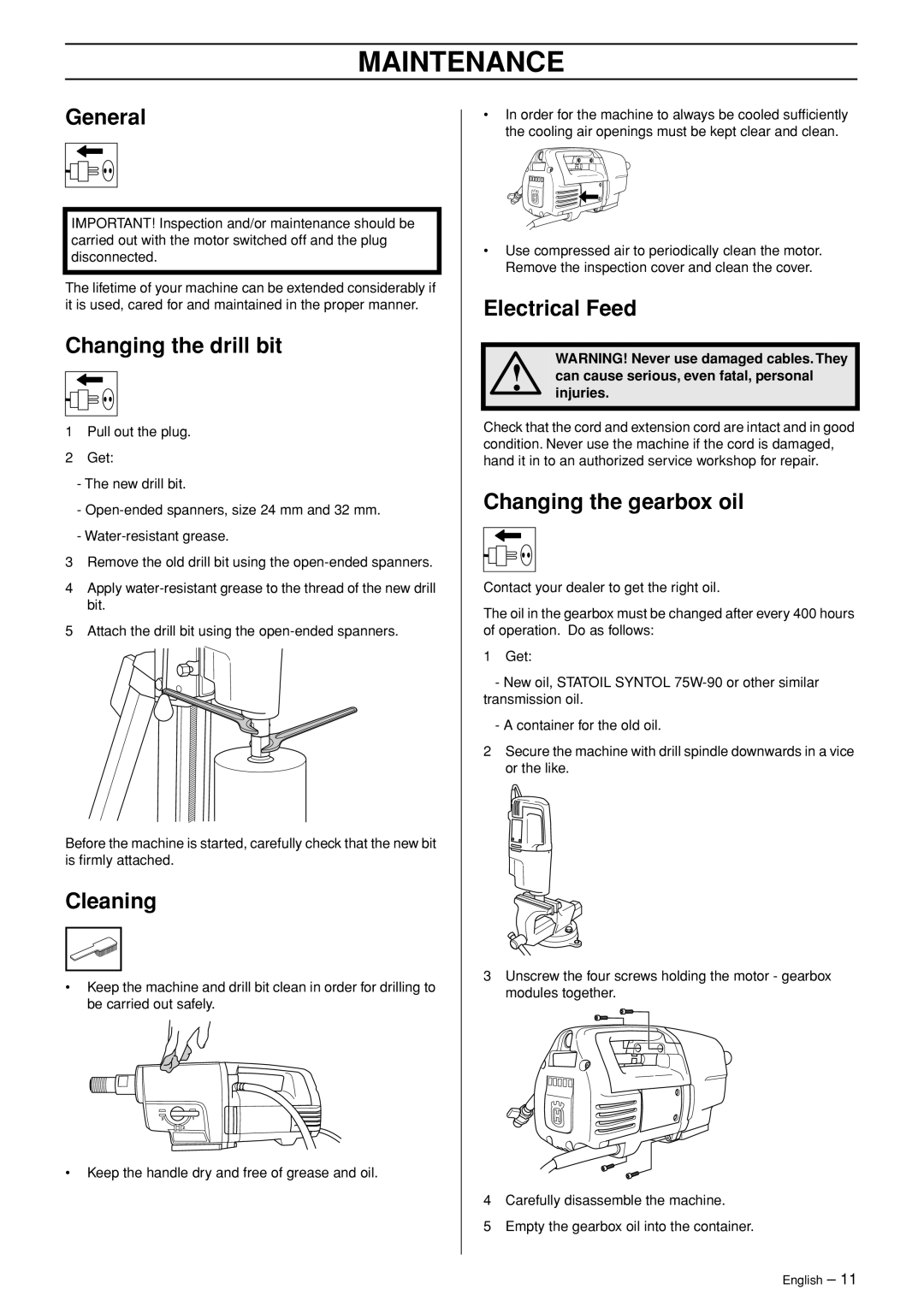

Changing the drill bit

1Pull out the plug.

2Get:

-The new drill bit.

-

-

3Remove the old drill bit using the

4Apply

5Attach the drill bit using the

Before the machine is started, carefully check that the new bit is firmly attached.

Cleaning

•Keep the machine and drill bit clean in order for drilling to be carried out safely.

•Keep the handle dry and free of grease and oil.

•In order for the machine to always be cooled sufficiently the cooling air openings must be kept clear and clean.

•Use compressed air to periodically clean the motor. Remove the inspection cover and clean the cover.

Electrical Feed

WARNING! Never use damaged cables. They

!can cause serious, even fatal, personal injuries.

Check that the cord and extension cord are intact and in good condition. Never use the machine if the cord is damaged, hand it in to an authorized service workshop for repair.

Changing the gearbox oil

Contact your dealer to get the right oil.

The oil in the gearbox must be changed after every 400 hours of operation. Do as follows:

1Get:

-New oil, STATOIL SYNTOL

-A container for the old oil.

2Secure the machine with drill spindle downwards in a vice or the like.

3Unscrew the four screws holding the motor - gearbox modules together.

4Carefully disassemble the machine.

5Empty the gearbox oil into the container.

English – 11