Diamond selection

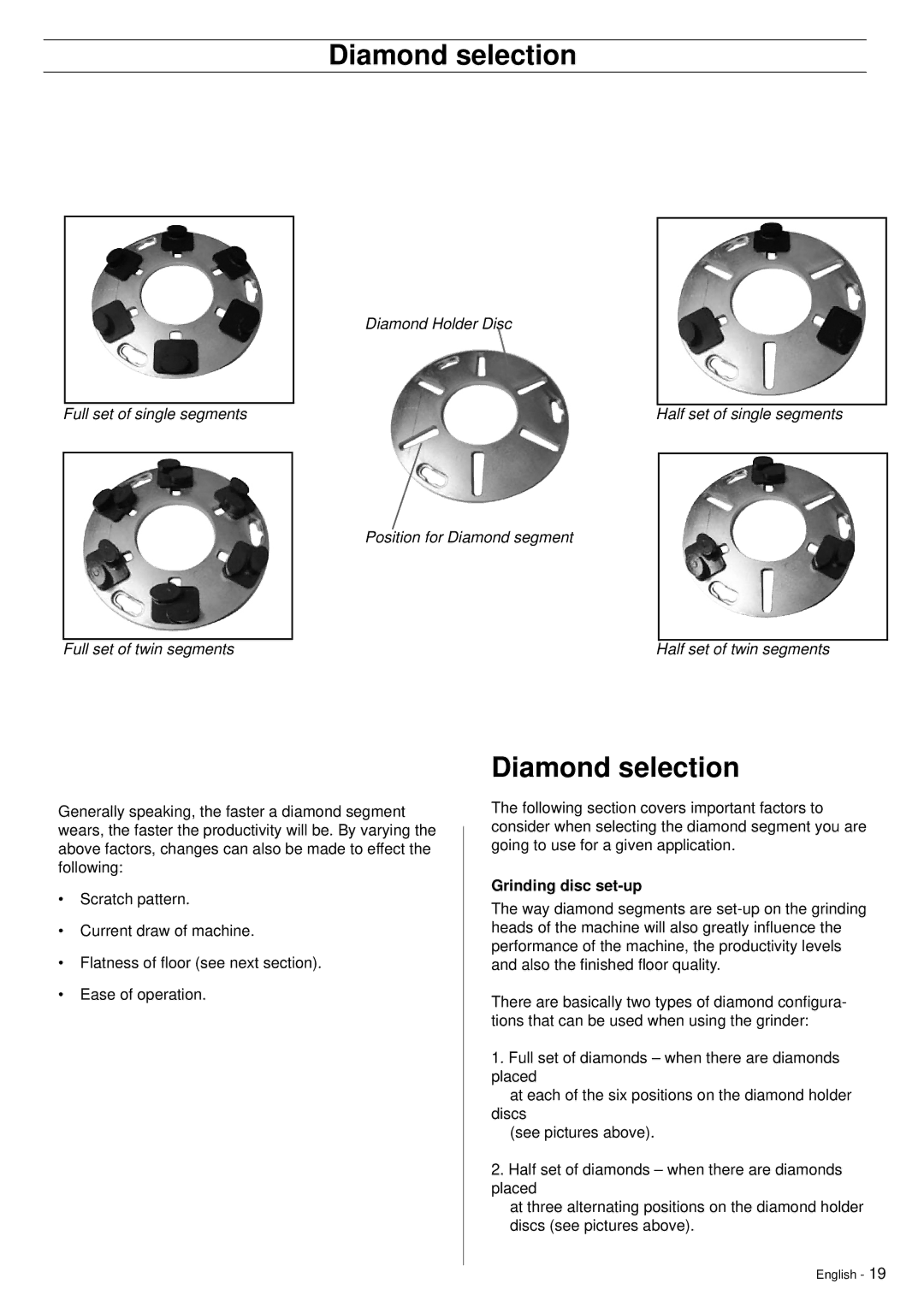

Diamond Holder Disc

Full set of single segments | Half set of single segments |

Position for Diamond segment

Full set of twin segments | Half set of twin segments |

Generally speaking, the faster a diamond segment wears, the faster the productivity will be. By varying the above factors, changes can also be made to effect the following:

•Scratch pattern.

•Current draw of machine.

•Flatness of floor (see next section).

•Ease of operation.

Diamond selection

The following section covers important factors to consider when selecting the diamond segment you are going to use for a given application.

Grinding disc set-up

The way diamond segments are

There are basically two types of diamond configura- tions that can be used when using the grinder:

1.Full set of diamonds – when there are diamonds placed

at each of the six positions on the diamond holder discs

(see pictures above).

2.Half set of diamonds – when there are diamonds placed

at three alternating positions on the diamond holder discs (see pictures above).

English - 19