LUBRICATION

Lubricating the Cables

If possible, lubricate both ends of the cables and move the controls to end stop positions when lubricating. Refit the rubber covers on the cables after lubrication. Cables with sheaths will bind if they are not lubricated regularly. If a cable binds, it can disrupt operation.

If a cable binds, remove the cable and hang it vertically. Lubricate it with thin engine oil until the oil begins to escape from the bottom.

Hint!: Fill a small plastic bag with oil and tape it so that it seals against the sheath and allow the cable to hang vertically from the bag overnight. If you do not succeed in lubricating the cable, it must be replaced.

Lubricating in Accordance with the Lubrication Schedule

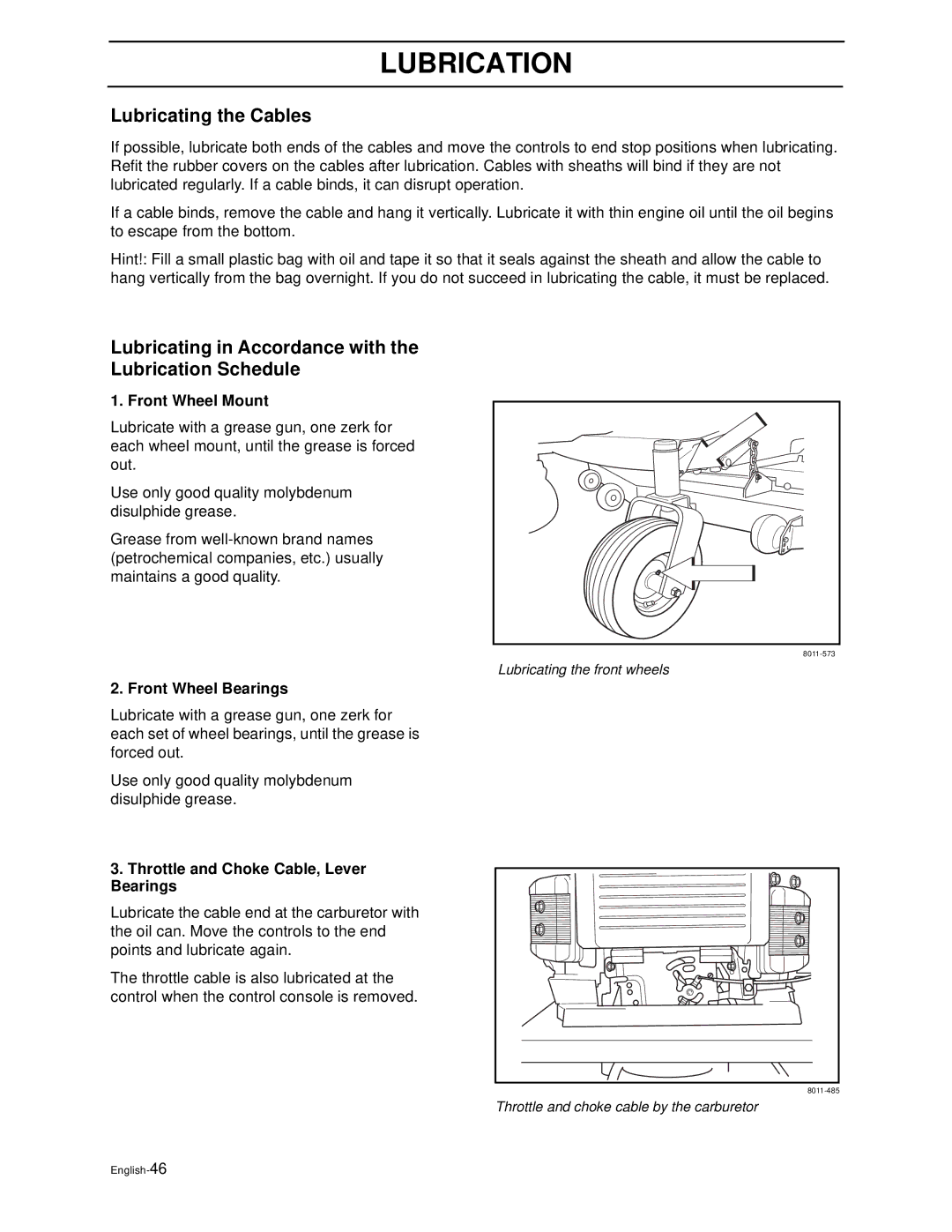

1. Front Wheel Mount

Lubricate with a grease gun, one zerk for each wheel mount, until the grease is forced out.

Use only good quality molybdenum disulphide grease.

Grease from

2. Front Wheel Bearings

Lubricate with a grease gun, one zerk for each set of wheel bearings, until the grease is forced out.

Use only good quality molybdenum disulphide grease.

3.Throttle and Choke Cable, Lever Bearings

Lubricate the cable end at the carburetor with the oil can. Move the controls to the end points and lubricate again.

The throttle cable is also lubricated at the control when the control console is removed.

Lubricating the front wheels

Throttle and choke cable by the carburetor