Reset

button

Indicator

Figure

air to pass.

The mowing conditions will determine the frequency of air filter element changing.

Super Z liquid |

|

cooled shown | Radiator cap |

Radiator

Screen

Overflow reservoir ![]()

Figure

Air restriction indicator

Some Hustler units have an air restriction indicator installed in the air cleaner. Fig.

Replace the element whenever the restriction indicator reaches the change filter red line. Check the indicator daily and replace element as needed or annually whichever occurs first.

Reset the indicator by pushing in on the yellow button after each element change. Fig,

Cooling system - liquid cooled units

Gasoline units

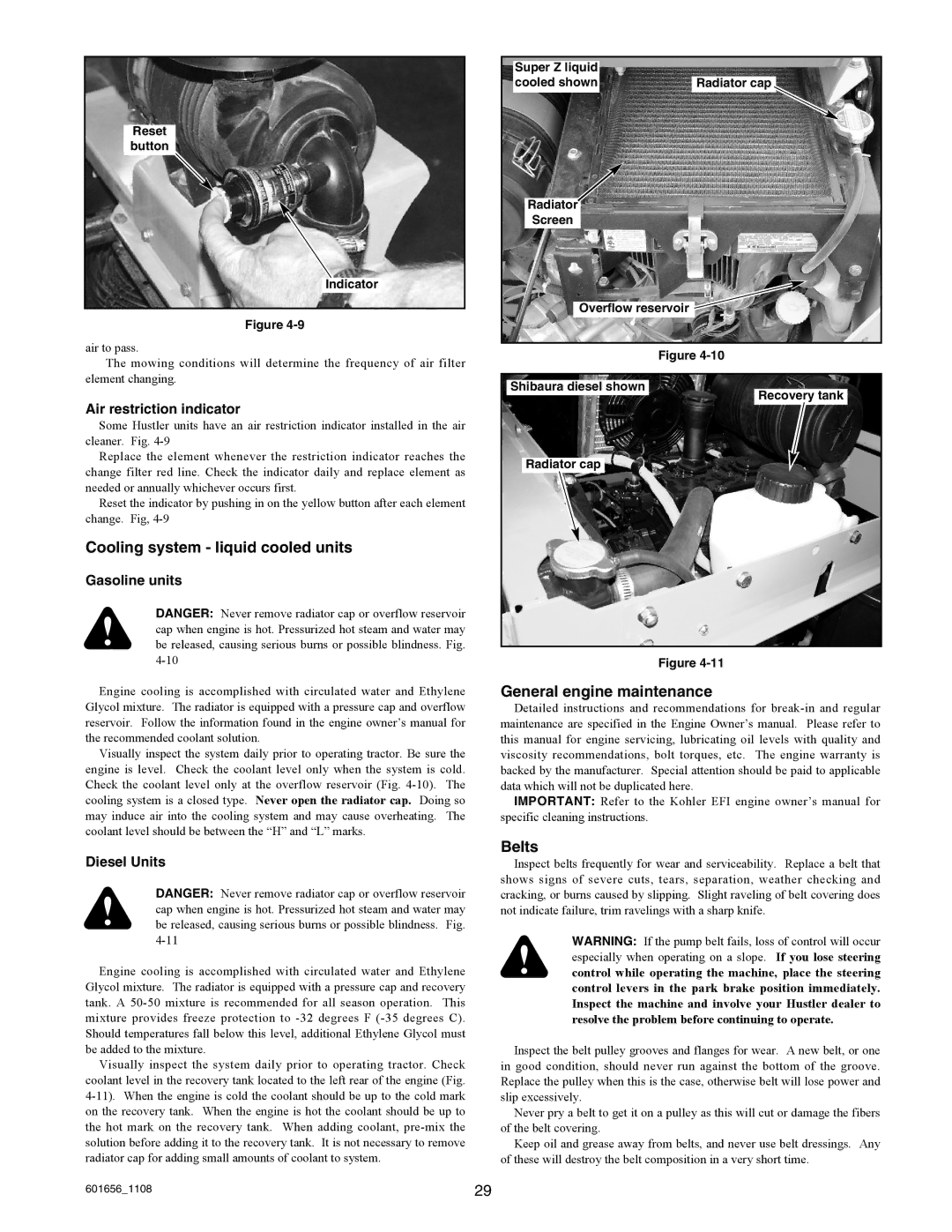

Shibaura diesel shown

Radiator cap

Recovery tank

DANGER: Never remove radiator cap or overflow reservoir cap when engine is hot. Pressurized hot steam and water may be released, causing serious burns or possible blindness. Fig.

Engine cooling is accomplished with circulated water and Ethylene Glycol mixture. The radiator is equipped with a pressure cap and overflow reservoir. Follow the information found in the engine owner’s manual for the recommended coolant solution.

Visually inspect the system daily prior to operating tractor. Be sure the engine is level. Check the coolant level only when the system is cold. Check the coolant level only at the overflow reservoir (Fig.

Diesel Units

DANGER: Never remove radiator cap or overflow reservoir cap when engine is hot. Pressurized hot steam and water may be released, causing serious burns or possible blindness. Fig.

Engine cooling is accomplished with circulated water and Ethylene Glycol mixture. The radiator is equipped with a pressure cap and recovery tank. A

Visually inspect the system daily prior to operating tractor. Check coolant level in the recovery tank located to the left rear of the engine (Fig.

Figure

General engine maintenance

Detailed instructions and recommendations for

IMPORTANT: Refer to the Kohler EFI engine owner’s manual for specific cleaning instructions.

Belts

Inspect belts frequently for wear and serviceability. Replace a belt that shows signs of severe cuts, tears, separation, weather checking and cracking, or burns caused by slipping. Slight raveling of belt covering does not indicate failure, trim ravelings with a sharp knife.

WARNING: If the pump belt fails, loss of control will occur especially when operating on a slope. If you lose steering control while operating the machine, place the steering control levers in the park brake position immediately. Inspect the machine and involve your Hustler dealer to resolve the problem before continuing to operate.

Inspect the belt pulley grooves and flanges for wear. A new belt, or one in good condition, should never run against the bottom of the groove. Replace the pulley when this is the case, otherwise belt will lose power and slip excessively.

Never pry a belt to get it on a pulley as this will cut or damage the fibers of the belt covering.

Keep oil and grease away from belts, and never use belt dressings. Any of these will destroy the belt composition in a very short time.

601656_1108 | 29 |