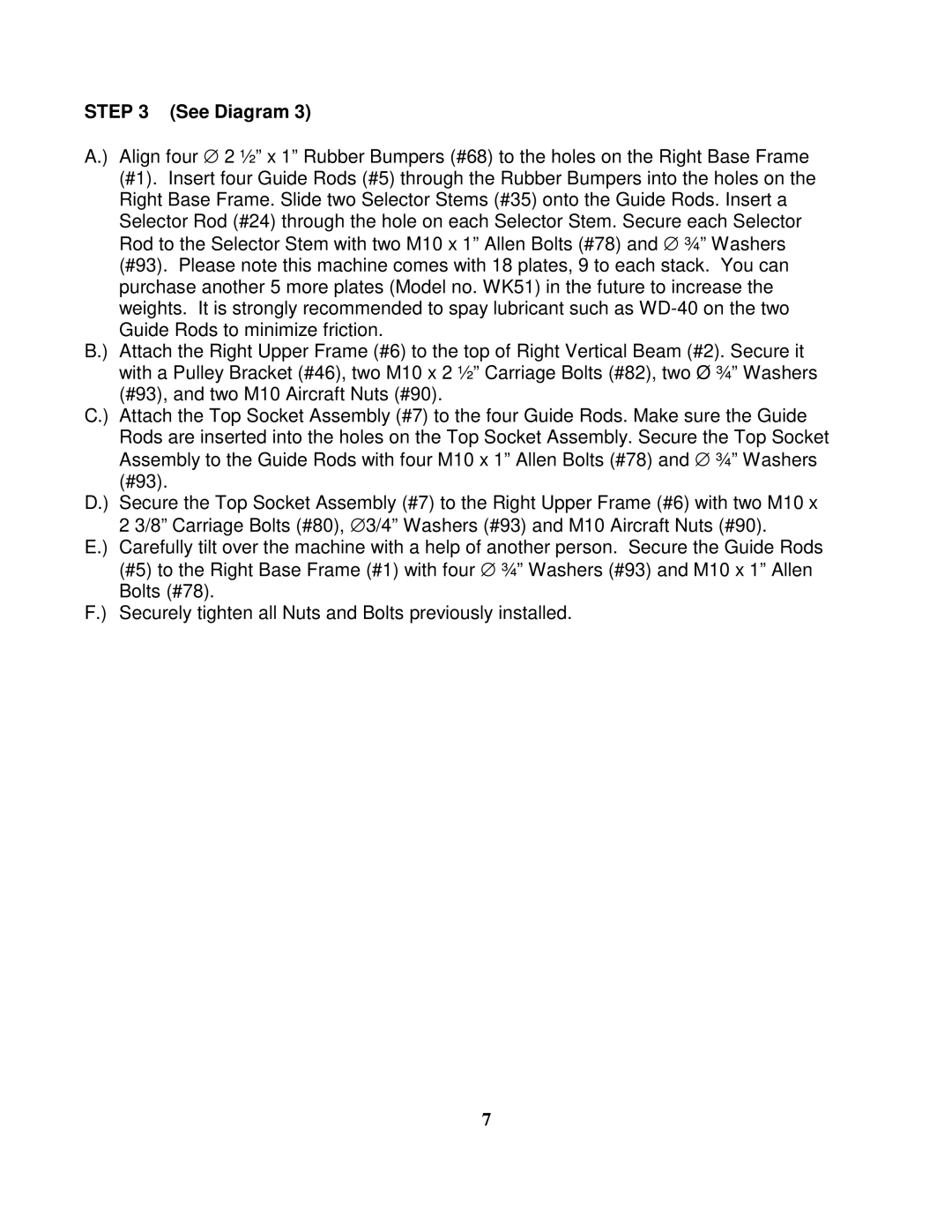

STEP 3 (See Diagram 3)

A.) | Align four ∅ 2 ½” x 1” Rubber Bumpers (#68) to the holes on the Right Base Frame |

| (#1). Insert four Guide Rods (#5) through the Rubber Bumpers into the holes on the |

| Right Base Frame. Slide two Selector Stems (#35) onto the Guide Rods. Insert a |

| Selector Rod (#24) through the hole on each Selector Stem. Secure each Selector |

| Rod to the Selector Stem with two M10 x 1” Allen Bolts (#78) and ∅ ¾” Washers |

| (#93). Please note this machine comes with 18 plates, 9 to each stack. You can |

| purchase another 5 more plates (Model no. WK51) in the future to increase the |

| weights. It is strongly recommended to spay lubricant such as |

| Guide Rods to minimize friction. |

B.) | Attach the Right Upper Frame (#6) to the top of Right Vertical Beam (#2). Secure it |

| with a Pulley Bracket (#46), two M10 x 2 ½” Carriage Bolts (#82), two Ø ¾” Washers |

| (#93), and two M10 Aircraft Nuts (#90). |

C.) | Attach the Top Socket Assembly (#7) to the four Guide Rods. Make sure the Guide |

| Rods are inserted into the holes on the Top Socket Assembly. Secure the Top Socket |

| Assembly to the Guide Rods with four M10 x 1” Allen Bolts (#78) and ∅ ¾” Washers |

| (#93). |

D.) | Secure the Top Socket Assembly (#7) to the Right Upper Frame (#6) with two M10 x |

| 2 3/8” Carriage Bolts (#80), ∅ 3/4” Washers (#93) and M10 Aircraft Nuts (#90). |

E.) | Carefully tilt over the machine with a help of another person. Secure the Guide Rods |

| (#5) to the Right Base Frame (#1) with four ∅ ¾” Washers (#93) and M10 x 1” Allen |

| Bolts (#78). |

F.) | Securely tighten all Nuts and Bolts previously installed. |

7