TROUBLE SHOOTING

LISTED BELOW ARE SOME OF THE MOST COMMON CAUSES FOR THE GRINDER | TO MALFUNCTION. | MALFUNCTIONS | BEYOND | THE SCOPE OF THIS MANUAL |

SHOULD BE BROUGHT TO THE ATTENTlON OF YOUR ARO REPRESENTATIVE | OR RETURN THE | TOOL TO THE FACTORY FOR | REPAIR. | |

CONDITION

LOW SPEED AND POWER OR GRIND- ER WILL NOT RUN.

THROTTLE VALVE HARD TO OPERATE.

TOOL WILL NOT SHUT OFF.

POSSIBLE CAUSE

1.INADEQUATE AIR SUPPLY.

2.AIR REGULATOR (30603) IMPROPER-

LY ADJUSTED.

3.AIR INLET OR EXHAUST SCREEN PLUGGED.

4.OBSTRUCTION IN THROTTLE VALVE OR VALVE NOT OPENING.

5.MOTOR NOT BEING PROPERLY LU- BRICATED.

6.ROTOR BLADE IS MISSING, INCOR- RECTLY INSTALLED, BADLY WORN OR BEARING FAILURE.

1.DAMAGED VALVE PIN OR COM- PONENTS.

1.DAMAGED VALVE COMPONENTS.

CORRECTIVE ACTION

1.CHECK AIR SUPPLY FOR CORRECT REGULATOR ADJUST- MENT (90 P.S.I.G. MAX. WHEN TOOL IS OPERATING).

2.CHECK REGULATOR ADJUSTMENT TO BE SURE OF MAXIMUM

AIR FLOW.

3.INSPECT, WASH CLEAN.

4.DISASSEMBLE THROTTLE, CLEAN, INSPECT FOR OBSTRUC- TIONS OR DAMAGED PARTS.

5.APPLY 2 OR 4 DROPS OF SPINDLE OIL IN AIR INLET. RUN TOOL TO ALLOW OIL TO ENTER MOTOR - BE CERTAIN OILER IS FULL OF OIL.

6.DISASSEMBLE MOTOR, CLEAN AND INSPECT FOR PROPER INSTALLATION, REPLACE BLADES AND/OR BEARINGS IF NEC- ESSARY.

1.DISASSEMBLE VALVE COMPONENTS, INSPECT, REPLACE IF NECESSARY.

1.DISASSEMBLE VALVE COMPONENTS, INSPECT, REPLACE PARTS IF NECESSARY.

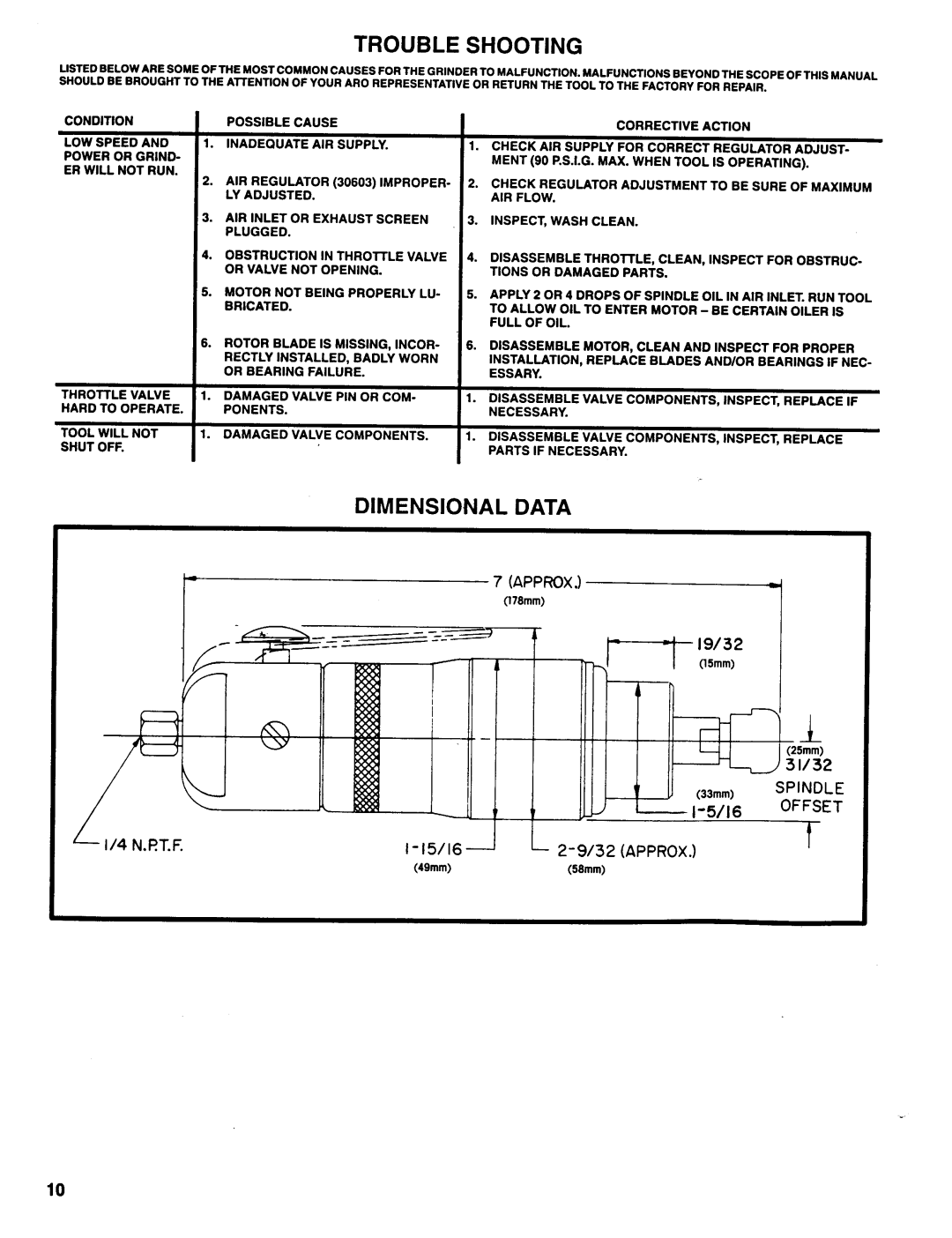

DIMENSIONAL DATA

2-9/32 (APPROX.)

(49mm)(56mm)

10