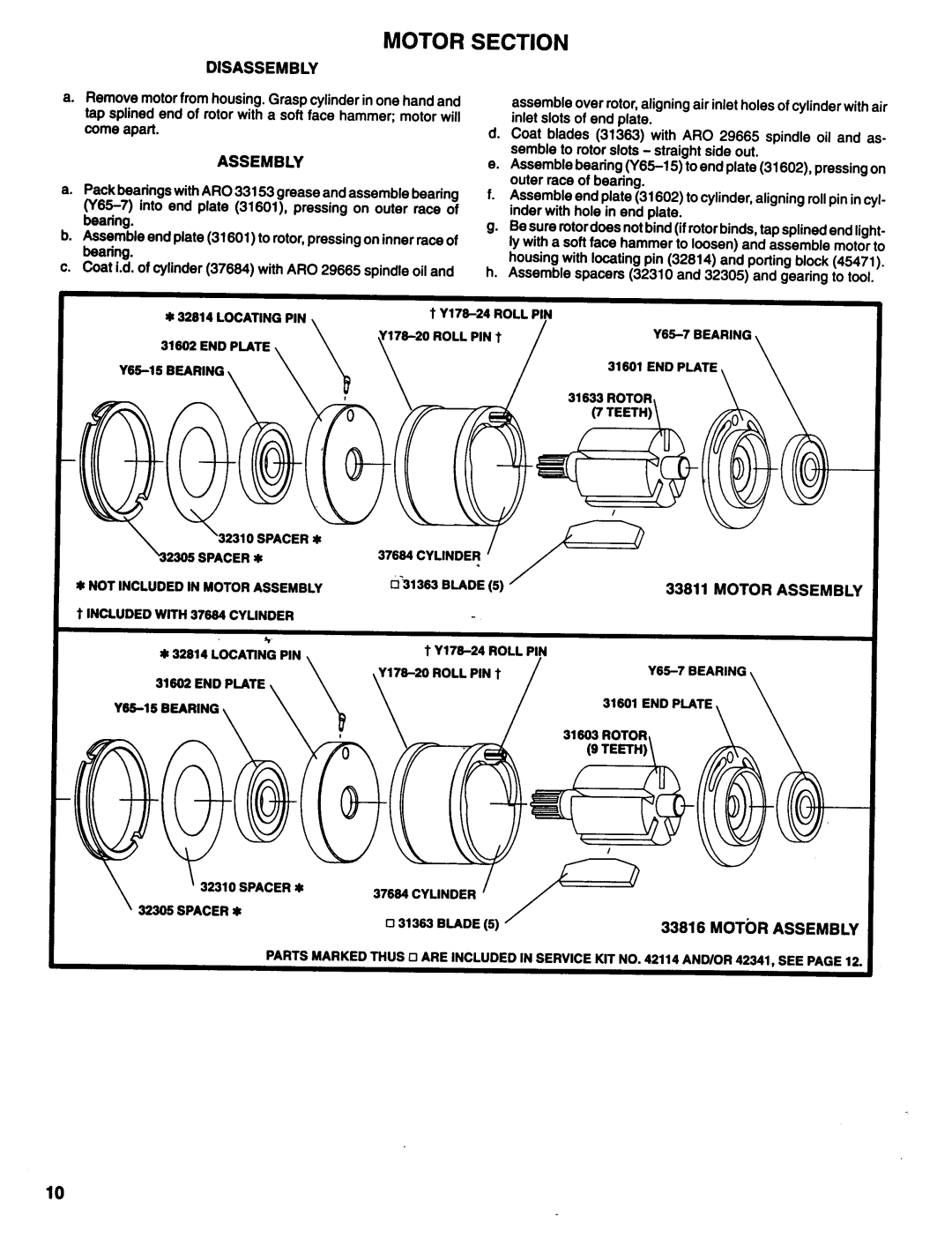

MOTOR SECTION

DISASSEMBLY

a.Remove motor from housing. Grasp cylinder in one hand and tap splined end of rotor with a soft face hammer; motor will come apart.

ASSEMBLY

a.Pack bearings with ARO 33153 grease and assemble bearing

b.Assemble end plate (31601) to rotor, pressing on inner race of bearing.

c. Coat i.d. of cylinder (37684) with ARO 29665 spindle oil and

assemble over rotor, aligning air inlet holes of cylinder with air inlet slots of end plate.

d.Coat blades (31363) with ARO 29665 spindle oil and as- semble to rotor slots - straight side out.

e.Assemble bearing

f.Assemble end plate (31602) to cylinder, aligning roll pin in cyl- inder with hole in end plate.

g.Be sure rotordoes not bind (if rotor binds, tap splined end light- ly with a soft face hammer to loosen) and assemble motor to housing with locating pin (32814) and porting block (45471).

h.Assemble spacers (32310 and 32305) and gearing to tool.

* 32614 LOCATING PIN | ||

31662 END PLATE | ||

| ||

31661 END PLATE | ||

| ||

| 31633 ROTOR |

32310 SPACER *

2366 SPACER *

*NOT INCLUDED IN MOTOR ASSEMBLY t INCLUDED WlTH 37664 CYLINDER

31662 END PLATE

37664 CYLINDER

33811 MOTOR ASSEMBLY

| 31601 END PLATE |

32310 SPACER $ | 37664 CYLINDER |

|

|

| |

32365 SPACER | 0 31363 BLADE (5) | 33816 MOTOR ASSEMBLY |

|

PARTS MARKED THUS 0 ARE INCLUDED IN SERVICE KIT NO. 42114 AND/OR 42341, SEE PAGE 12.

10