General Maintenance

Diamond Equipment recommends this maintenance information for regular service. Sustained heavy operation may call for more frequent service. Snowplowing subjects a vehicle to exceptionally rugged use. As a result, it is important to inspect and bring the snowplow and vehicle up to maximum operating conditions. Inspection should be made of both the vehicle and snowplow prior to the plowing season and after each use.

Pre-Season Maintenance

Scheduled vehicle maintenance should be performed as recommended by the manufacturer.

Don't forget that in addition to keeping equipment in order:

1.Keep windshield wipers, heaters and lights working.

2.Diamond offers as standard equipment quartz halogen snowplow lights for even brighter illumination.

3.Equip vehicles with chains where necessary.

4.Provide operators with protective clothing and with rubber gloves for handling snow melting chemicals.

VEHICLE ELECTRICAL

1.Battery terminals to assure they're clean and free of corrosion.

2.Electrical connections, to assure they're tight and

3.Battery must be in top operating condition.

4.Alternator and regulator, to assure maximum electrical output.

SNOWPLOW

NOTE: ALWAYS lower moldboard to ground when vehicle is not in use. Check the Troubleshooting Chart, pages

1.Check and maintain hydraulic fluid reservoir level to 1 " - 1 1/2" from top cap. (Lift cylinder in down position.)

2.Check entire hydraulic system for leaks. A significant drop in hydraulic fluid level is evidence of a leak which must be corrected to prevent serious damage. See page 19

3.Before and after each season, remove sector pivot pins, thoroughly grease pivot tubes and reinstall pins. Lubricate all pivot points with chassis lube.

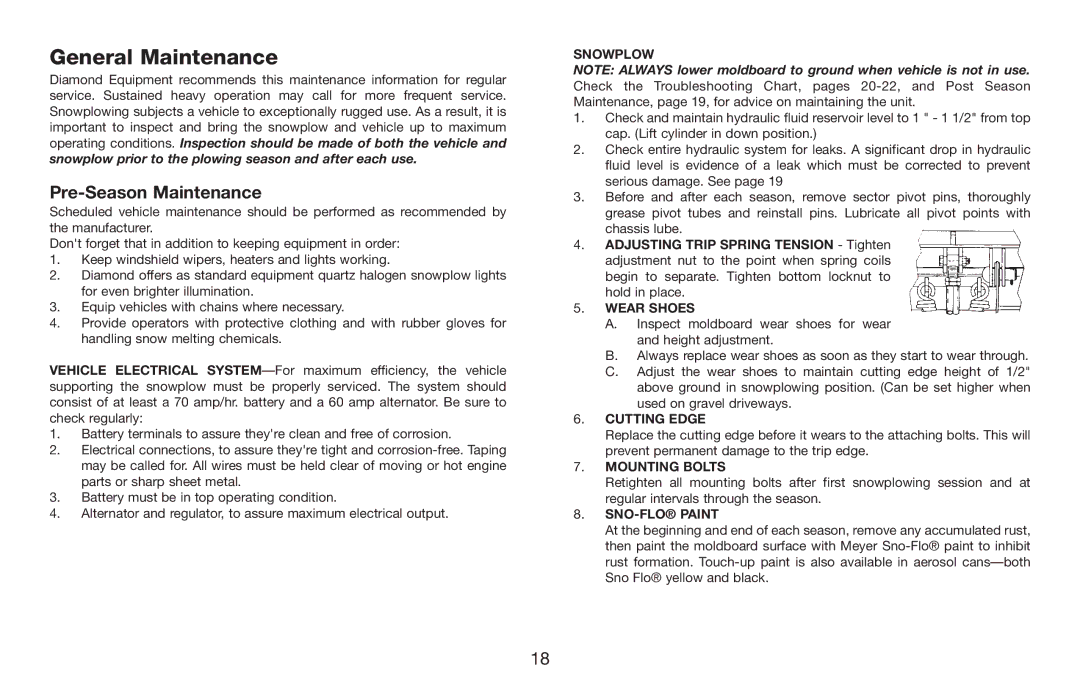

4.ADJUSTING TRIP SPRING TENSION - Tighten adjustment nut to the point when spring coils begin to separate. Tighten bottom locknut to hold in place.

5.WEAR SHOES

A.Inspect moldboard wear shoes for wear and height adjustment.

B.Always replace wear shoes as soon as they start to wear through.

C.Adjust the wear shoes to maintain cutting edge height of 1/2" above ground in snowplowing position. (Can be set higher when used on gravel driveways.

6.CUTTING EDGE

Replace the cutting edge before it wears to the attaching bolts. This will prevent permanent damage to the trip edge.

7.MOUNTING BOLTS

Retighten all mounting bolts after first snowplowing session and at regular intervals through the season.

8.SNO-FLO® PAINT

At the beginning and end of each season, remove any accumulated rust, then paint the moldboard surface with Meyer

18