1.Place one end of a

2.Adjust tension to approximately

found at the end of the coil spring on the rear of the bandsaw.

3.Connect the machine to the power source.

Vise Adjustment

To position the moveable vise jaw: | c |

|

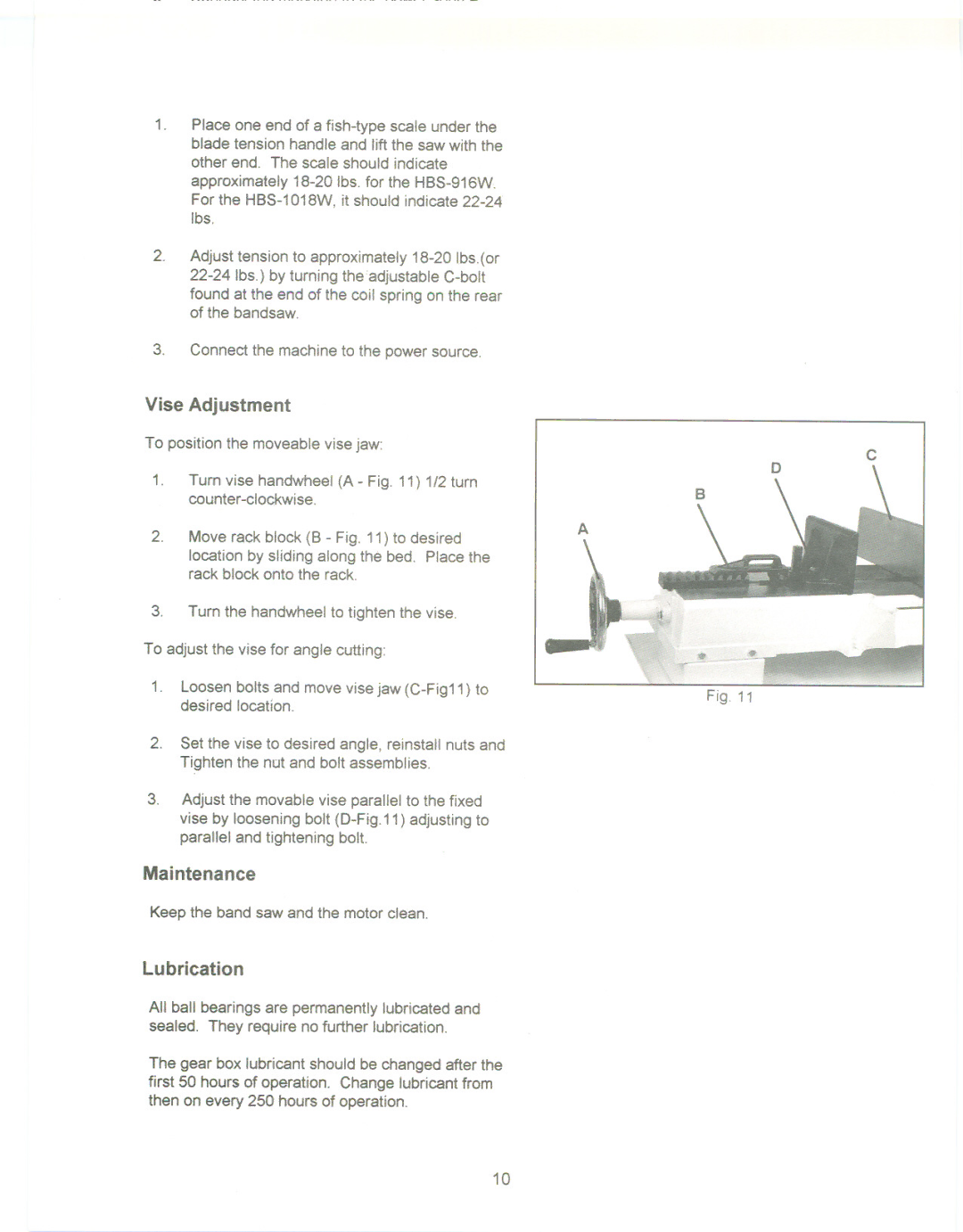

1.Turn vise handwheel (A - Fig. 11) 1/2 turn

2.Move rack block (B - Fig. 11) to desired

location by sliding along the bed. Place the rack block onto the rack.

3.Turn the handwheel to tighten the vise.

To adjust the vise for angle cutting:

1.Loosen bolts and move vise jaw

2.Set the vise to desired angle, reinstall nuts and Tighten the nut and bolt assemblies.

3.Adjust the movable vise parallel to the fixed vise by loosening bolt

Maintenance

Keep the band saw and the motor clean.

Lubrication

All ball bearings are permanently lubricated and sealed. They require no further lubrication.

The gear box lubricant should be changed after the first 50 hours of operation. Change lubricant from then on every 250 hours of operation.

10