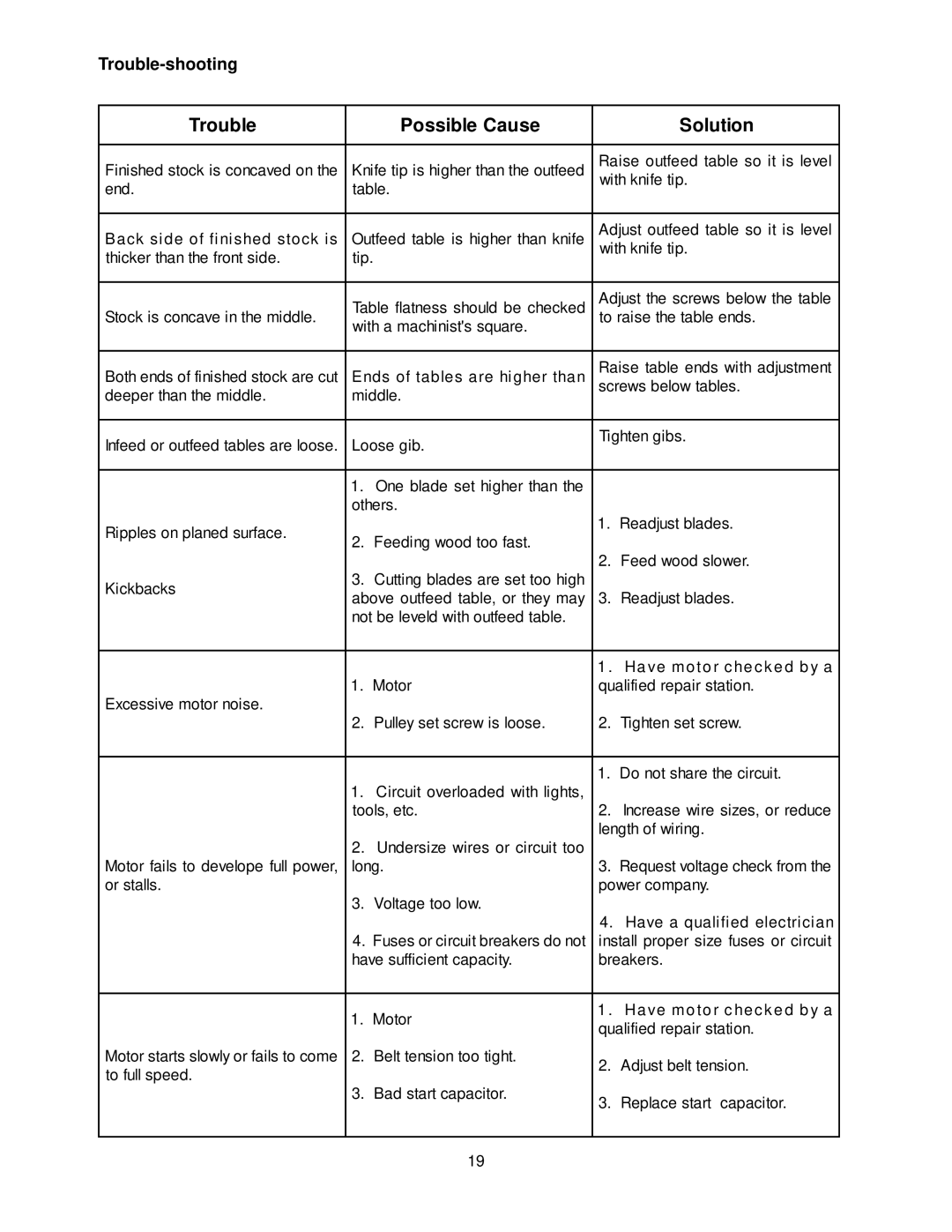

Trouble-shooting

Trouble |

| Possible Cause |

| Solution | |

|

|

|

| ||

Finished stock is concaved on the | Knife tip is higher than the outfeed | Raise outfeed table so it is level | |||

with knife tip. | |||||

end. | table. |

|

| ||

|

|

|

| ||

B ack si de of fi ni shed stock i s | Outfeed table is higher than knife | Adjust outfeed table so it is level | |||

with knife tip. | |||||

thicker than the front side. | tip. |

|

| ||

|

|

| |||

Stock is concave in the middle. | Table flatness should be checked | Adjust the screws below the table | |||

with a machinist's square. | to raise the table ends. | ||||

|

|

| |||

|

|

|

| ||

Both ends of finished stock are cut | Ends of tables are hi gher than | Raise table ends with adjustment | |||

screws below tables. | |||||

deeper than the middle. | middle. |

|

| ||

|

|

|

| ||

Infeed or outfeed tables are loose. | Loose gib. | Tighten gibs. | |||

|

| ||||

|

|

|

| ||

| 1. One blade set higher than the |

|

| ||

| others. |

|

| ||

Ripples on planed surface. |

|

| 1. | Readjust blades. | |

2. Feeding wood too fast. |

|

| |||

|

|

| |||

|

|

| 2. | Feed wood slower. | |

Kickbacks | 3. Cutting blades are set too high |

|

| ||

above outfeed table, or they may | 3. | Readjust blades. | |||

| |||||

| not be leveld with outfeed table. |

|

| ||

|

|

|

| ||

|

|

| 1 . Ha ve m o to r c he c k e d b y a | ||

| 1. | Motor | qualified repair station. | ||

Excessive motor noise. |

|

|

|

| |

| 2. | Pulley set screw is loose. | 2. | Tighten set screw. | |

|

|

|

| ||

|

|

| 1. Do not share the circuit. | ||

| 1. Circuit overloaded with lights, |

|

| ||

| tools, etc. | 2. | Increase wire sizes, or reduce | ||

|

|

| length of wiring. | ||

| 2. Undersize wires or circuit too |

|

| ||

Motor fails to develope full power, | long. | 3. Request voltage check from the | |||

or stalls. |

|

| power company. | ||

| 3. | Voltage too low. |

|

| |

|

|

| 4. Have a qualified electrician | ||

| 4. Fuses or circuit breakers do not | install proper size fuses or circuit | |||

| have sufficient capacity. | breakers. | |||

|

|

|

| ||

| 1. | Motor | 1 . Ha ve m o to r c he c k e d b y a | ||

| qualified repair station. | ||||

|

|

| |||

Motor starts slowly or fails to come | 2. | Belt tension too tight. | 2. | Adjust belt tension. | |

to full speed. |

|

| |||

|

|

|

| ||

| 3. | Bad start capacitor. | 3. | Replace start capacitor. | |

|

|

| |||

|

|

|

|

| |

19