Jointing Warped Material

If the work to be jointed is cupped or warped, take light, repetitive cuts until the surface is flat. Forc- ing the material flat against the table will still leave a warped piece after the cuts have been made.

WARNING

Never joint any material shorter than eight

inches!

The material may tip into the jointer’s throat and be kicked back!

Avoid jointing thin material which could become jammed under the fence or blade guard!

Failure to comply may cause serious injury!

the knives, and they will take a “bite” from the work with a tendency to kick back unless the piece is held firmly. Push the work forward as in ordinary jointing. The effect is to plane off all the stock in front of the knives to an increasing depth, leaving a tapered surface.

The ridge left by the knives when starting the taper may be removed by taking a very light cut in the regular jointing procedure, with the infeed table raised to its normal position.

Practice is required in this operation. Beginners are advised to make trial cuts with scrap material.

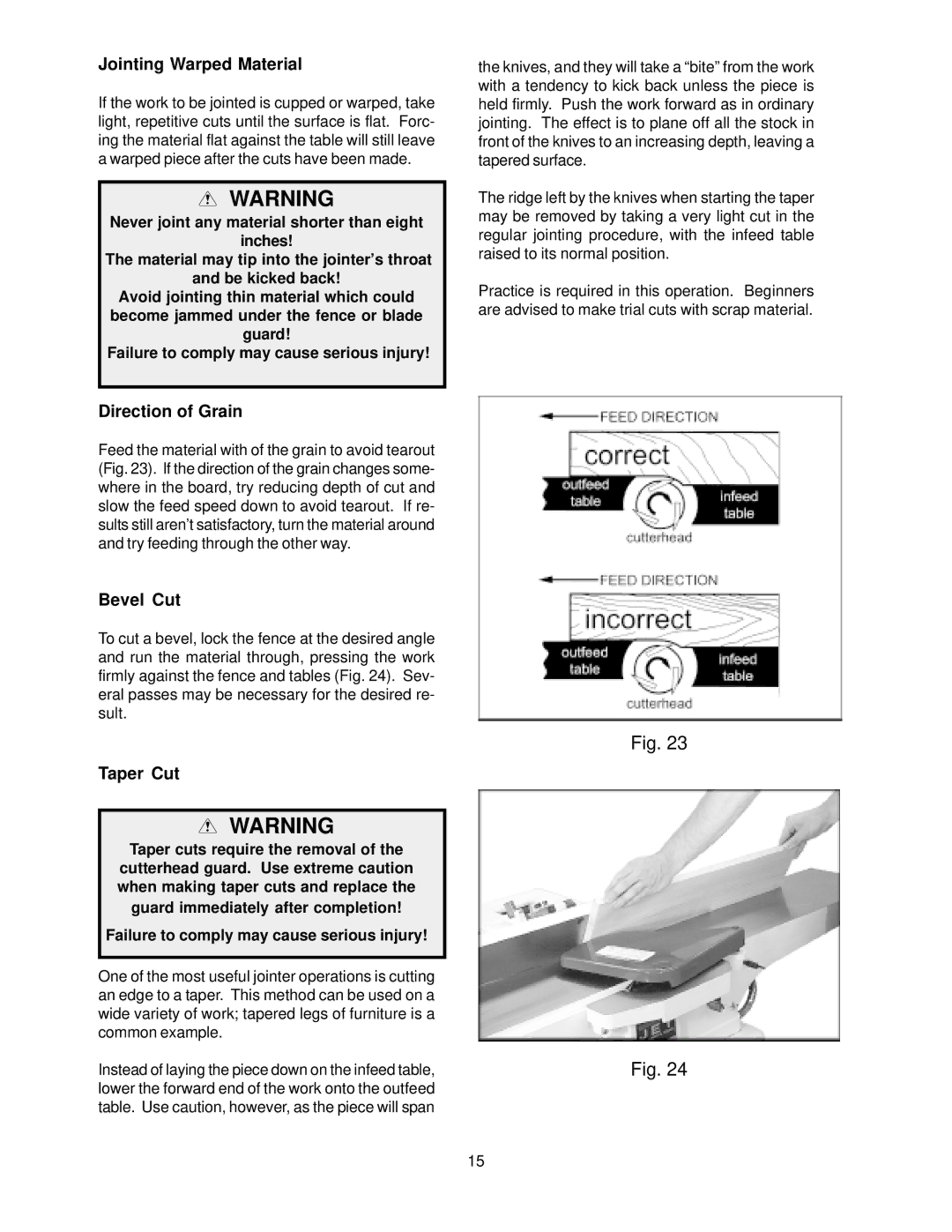

Direction of Grain

Feed the material with of the grain to avoid tearout (Fig. 23). If the direction of the grain changes some- where in the board, try reducing depth of cut and slow the feed speed down to avoid tearout. If re- sults still aren’t satisfactory, turn the material around and try feeding through the other way.

Bevel Cut

To cut a bevel, lock the fence at the desired angle and run the material through, pressing the work firmly against the fence and tables (Fig. 24). Sev- eral passes may be necessary for the desired re- sult.

Fig. 23

Taper Cut

WARNING |

|

Taper cuts require the removal of the |

|

cutterhead guard. Use extreme caution |

|

when making taper cuts and replace the |

|

guard immediately after completion! |

|

Failure to comply may cause serious injury! |

|

One of the most useful jointer operations is cutting |

|

an edge to a taper. This method can be used on a |

|

wide variety of work; tapered legs of furniture is a |

|

common example. |

|

Instead of laying the piece down on the infeed table, | Fig. 24 |

lower the forward end of the work onto the outfeed |

|

table. Use caution, however, as the piece will span |

|

15