Mounting the Work

Move the tailstock to approximately 1 to

the end of the work piece and lock in position. Turn the tailstock handwheel until the center makes

contact with the work piece. Continue to turn the hand wheel and slowly rotate the work piece by hand. After the work piece becomes difficult to turn by hand, reverse the hand wheel approximatelyone quarter turn and lock the tailstock spindle (Fig. 10)

Adjusting the Tool Rest

Position the tool rest approximately 1/8" away from the work piece and 1/8" above the work centerline. After some experience has been gained, this position can be varied slightly to suit the operation.

Position of Hands

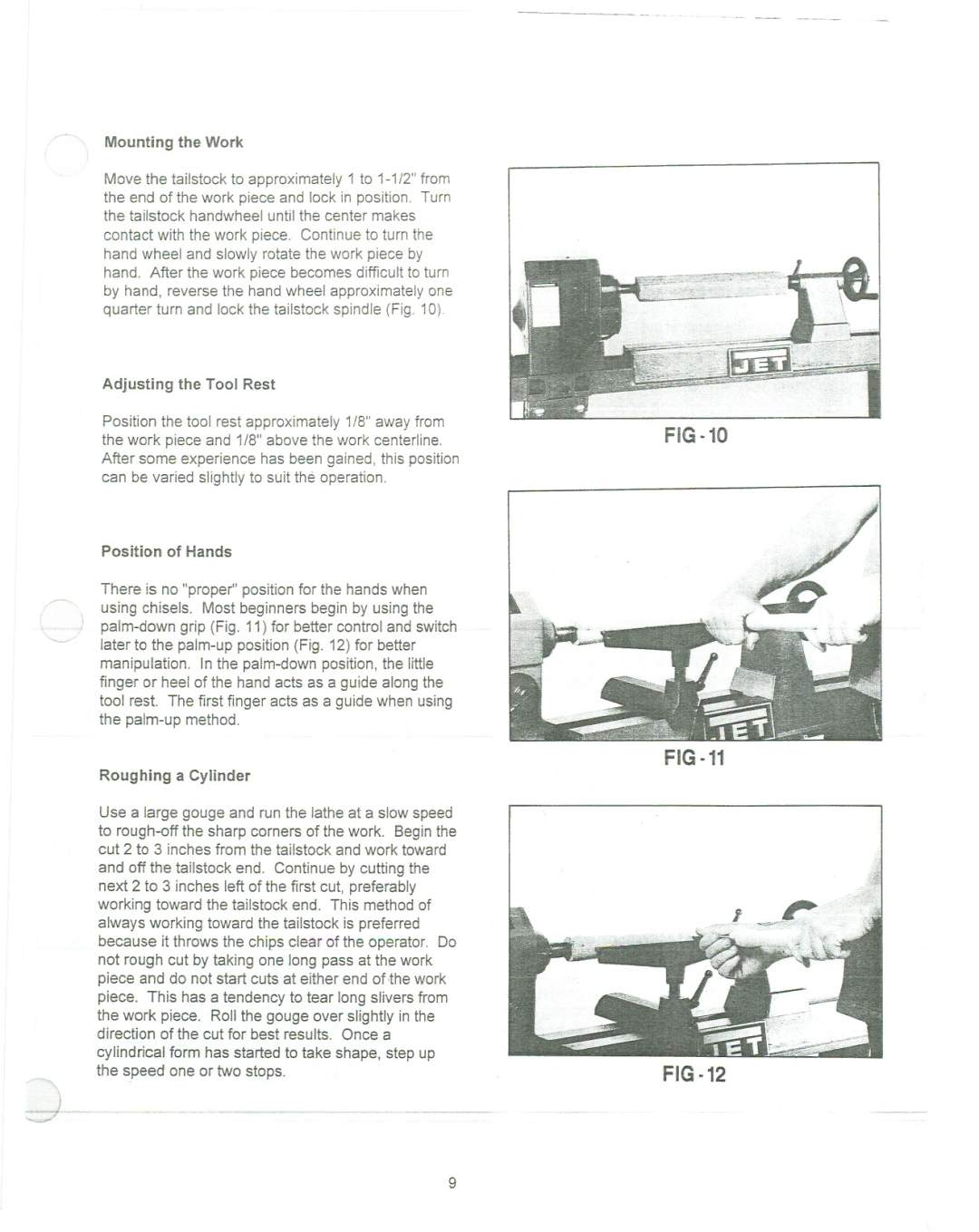

There is no "proper" position for the hands when

using chisels. Most beginners begin by using the

)

Roughing a Cylinder

Use a large gouge and run the lathe at a slow speed

to

and off the tailstock end. Continue by cutting the next 2 to 3 inches left of the first cut, preferably working toward the tailstock end. This method of always working toward the tailstock is preferred because it throws the chips clear of the operator. Do not rough cut by taking one long pass at the work piece and do not start cuts at either end ofthe work piece. This has a tendency to tear long slivers from

the work piece. Roll the gouge over slightly in the direction of the cut for best results. Once a

cylindrical form has started to take shape, step up the speed one or two stops.

FIG

FIG

FIG

9