Maintenance

Periodic or regular inspections are required to ensure that the machine is in proper adjustment, that all screws are tight, that belts are in good condition, that dust has not accumulated in the electrical enclosures, and that there are no worn or loose electrical connections.

Buildup of sawdust and other debris can cause your machine to plane inaccurately. Periodic cleaning is not only recommended but mandatory for accurate planing.

Remove resin and other accumulations from feed rollers and table with a soft rag and non- flammable solvent.

Periodically check all the chains for proper tension and adjust accordingly if required.

Tip: If a foreign object nicks the knives, instead of throwing them away or trying to grind out the deep nick, simply stagger the knives in the head, moving one knife no more than 1/4" to the right and another knife no more than 1/4" to the left. The nick should no longer be noticeable.

The table should be kept clean and free of rust. Some users prefer a paste wax coating. Another option is talcum powder applied with a blackboard eraser rubbed in vigorously once a week; this will fill casting pores and form a moisture barrier. This method provides a table top that is slick and allows rust rings to be easily wiped from the surface. Important also is the fact that talcum powder will not stain wood or mar finishes as wax pickup does.

Lubrication

The bearings on the cutterhead are factory lubricated and sealed for life – no lubrication required.

The lubricant in the gearbox must be replaced every 2,500 hours.

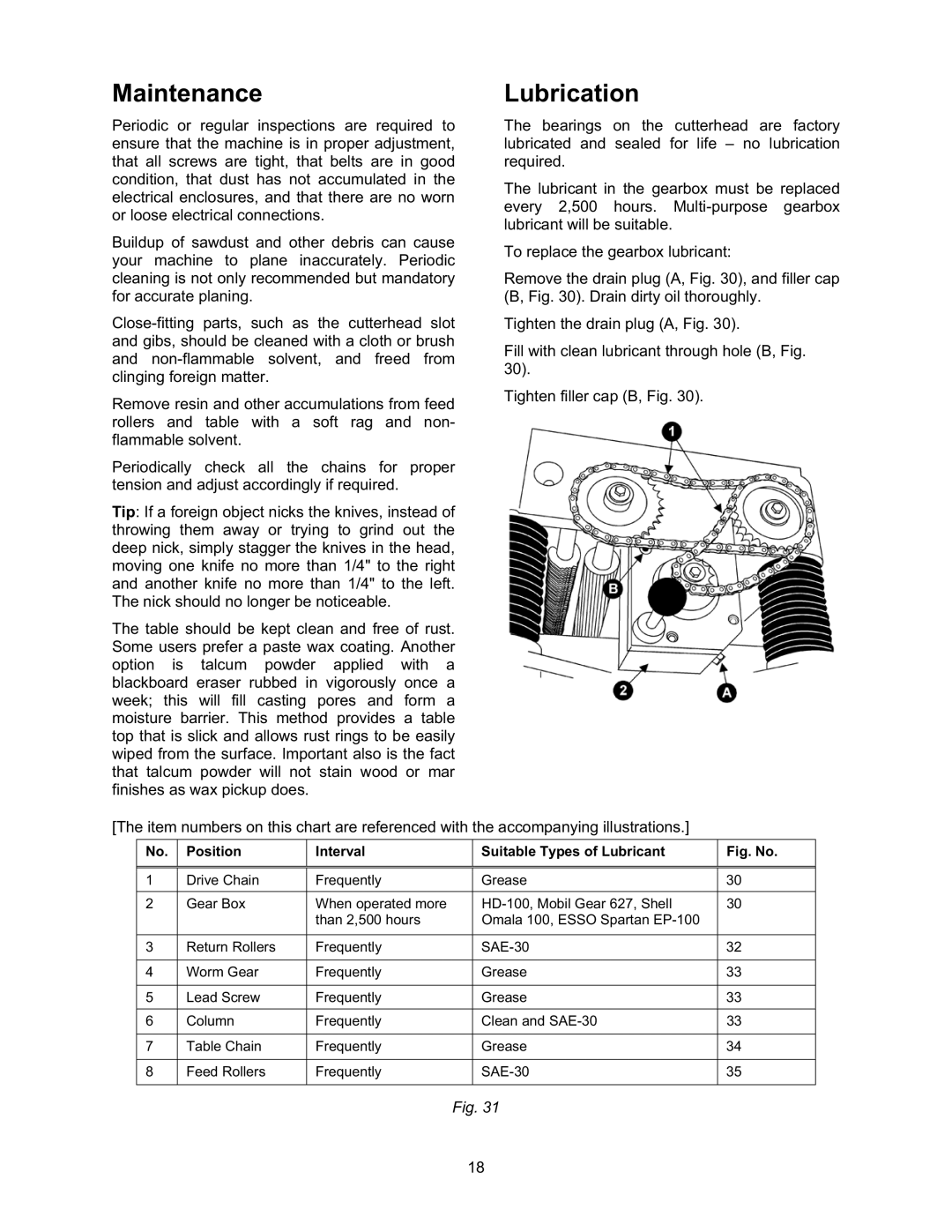

To replace the gearbox lubricant:

Remove the drain plug (A, Fig. 30), and filler cap (B, Fig. 30). Drain dirty oil thoroughly.

Tighten the drain plug (A, Fig. 30).

Fill with clean lubricant through hole (B, Fig. 30).

Tighten filler cap (B, Fig. 30).

[The item numbers on this chart are referenced with the accompanying illustrations.]

No. | Position | Interval | Suitable Types of Lubricant | Fig. No. |

|

|

|

|

|

1 | Drive Chain | Frequently | Grease | 30 |

|

|

|

|

|

2 | Gear Box | When operated more | 30 | |

|

| than 2,500 hours | Omala 100, ESSO Spartan |

|

|

|

|

|

|

3 | Return Rollers | Frequently | 32 | |

|

|

|

|

|

4 | Worm Gear | Frequently | Grease | 33 |

|

|

|

|

|

5 | Lead Screw | Frequently | Grease | 33 |

|

|

|

|

|

6 | Column | Frequently | Clean and | 33 |

|

|

|

|

|

7 | Table Chain | Frequently | Grease | 34 |

|

|

|

|

|

8 | Feed Rollers | Frequently | 35 | |

|

|

|

|

|

Fig. 31

18