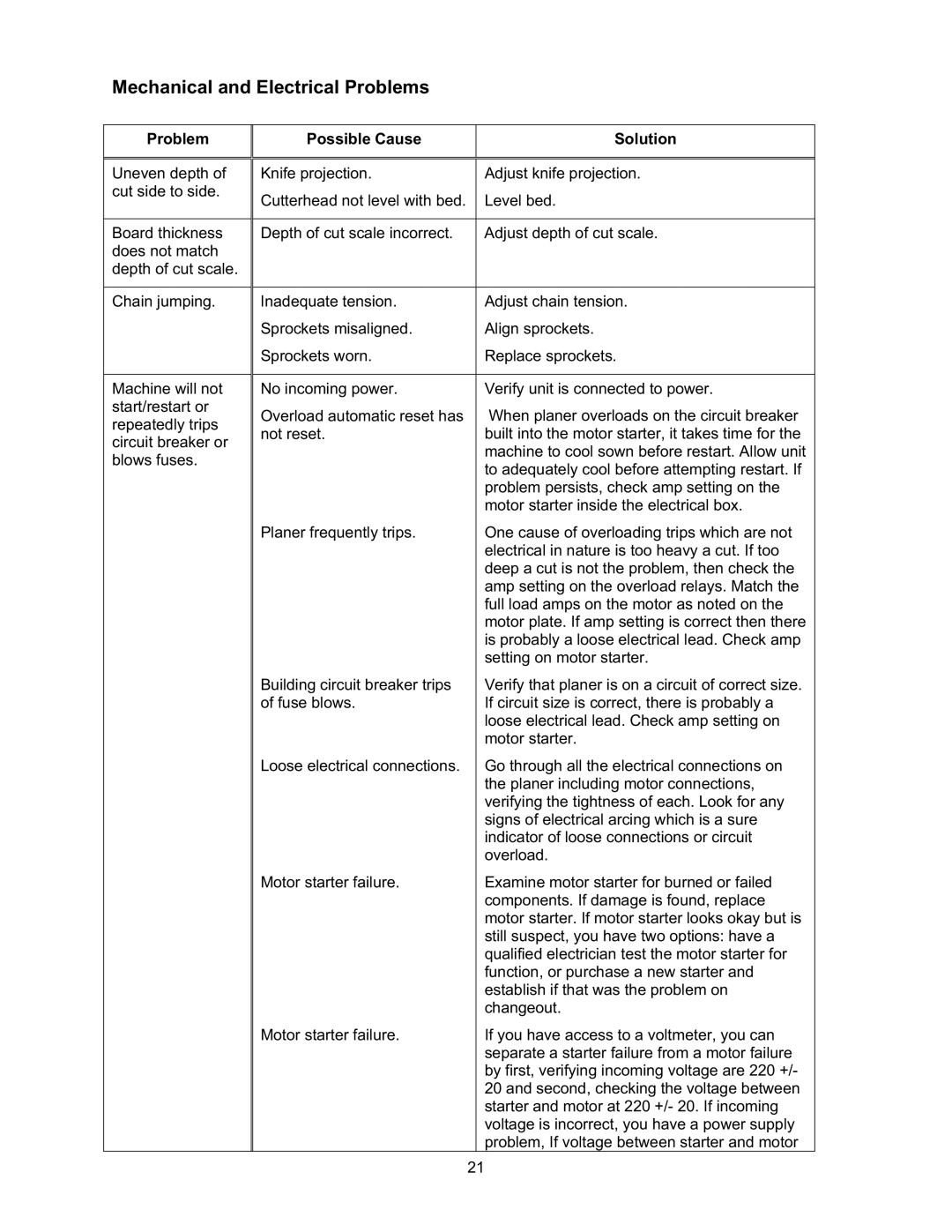

Mechanical and Electrical Problems

Problem

Uneven depth of cut side to side.

Board thickness does not match depth of cut scale.

Chain jumping.

Machine will not start/restart or repeatedly trips circuit breaker or blows fuses.

Possible Cause | Solution |

|

|

Knife projection. | Adjust knife projection. |

Cutterhead not level with bed. | Level bed. |

|

|

Depth of cut scale incorrect. | Adjust depth of cut scale. |

|

|

Inadequate tension. | Adjust chain tension. |

Sprockets misaligned. | Align sprockets. |

Sprockets worn. | Replace sprockets. |

|

|

No incoming power. | Verify unit is connected to power. |

Overload automatic reset has | When planer overloads on the circuit breaker |

not reset. | built into the motor starter, it takes time for the |

| machine to cool sown before restart. Allow unit |

| to adequately cool before attempting restart. If |

| problem persists, check amp setting on the |

| motor starter inside the electrical box. |

Planer frequently trips. | One cause of overloading trips which are not |

| electrical in nature is too heavy a cut. If too |

| deep a cut is not the problem, then check the |

| amp setting on the overload relays. Match the |

| full load amps on the motor as noted on the |

| motor plate. If amp setting is correct then there |

| is probably a loose electrical lead. Check amp |

| setting on motor starter. |

Building circuit breaker trips | Verify that planer is on a circuit of correct size. |

of fuse blows. | If circuit size is correct, there is probably a |

| loose electrical lead. Check amp setting on |

| motor starter. |

Loose electrical connections. | Go through all the electrical connections on |

| the planer including motor connections, |

| verifying the tightness of each. Look for any |

| signs of electrical arcing which is a sure |

| indicator of loose connections or circuit |

| overload. |

Motor starter failure. | Examine motor starter for burned or failed |

| components. If damage is found, replace |

| motor starter. If motor starter looks okay but is |

| still suspect, you have two options: have a |

| qualified electrician test the motor starter for |

| function, or purchase a new starter and |

| establish if that was the problem on |

| changeout. |

Motor starter failure. | If you have access to a voltmeter, you can |

| separate a starter failure from a motor failure |

| by first, verifying incoming voltage are 220 +/- |

| 20 and second, checking the voltage between |

| starter and motor at 220 +/- 20. If incoming |

| voltage is incorrect, you have a power supply |

| problem, If voltage between starter and motor |

21