Welding

it:, CAUTION

The welder is designed for intermittent use. Repeated welding within a short period of time may cause the welder to overheat.

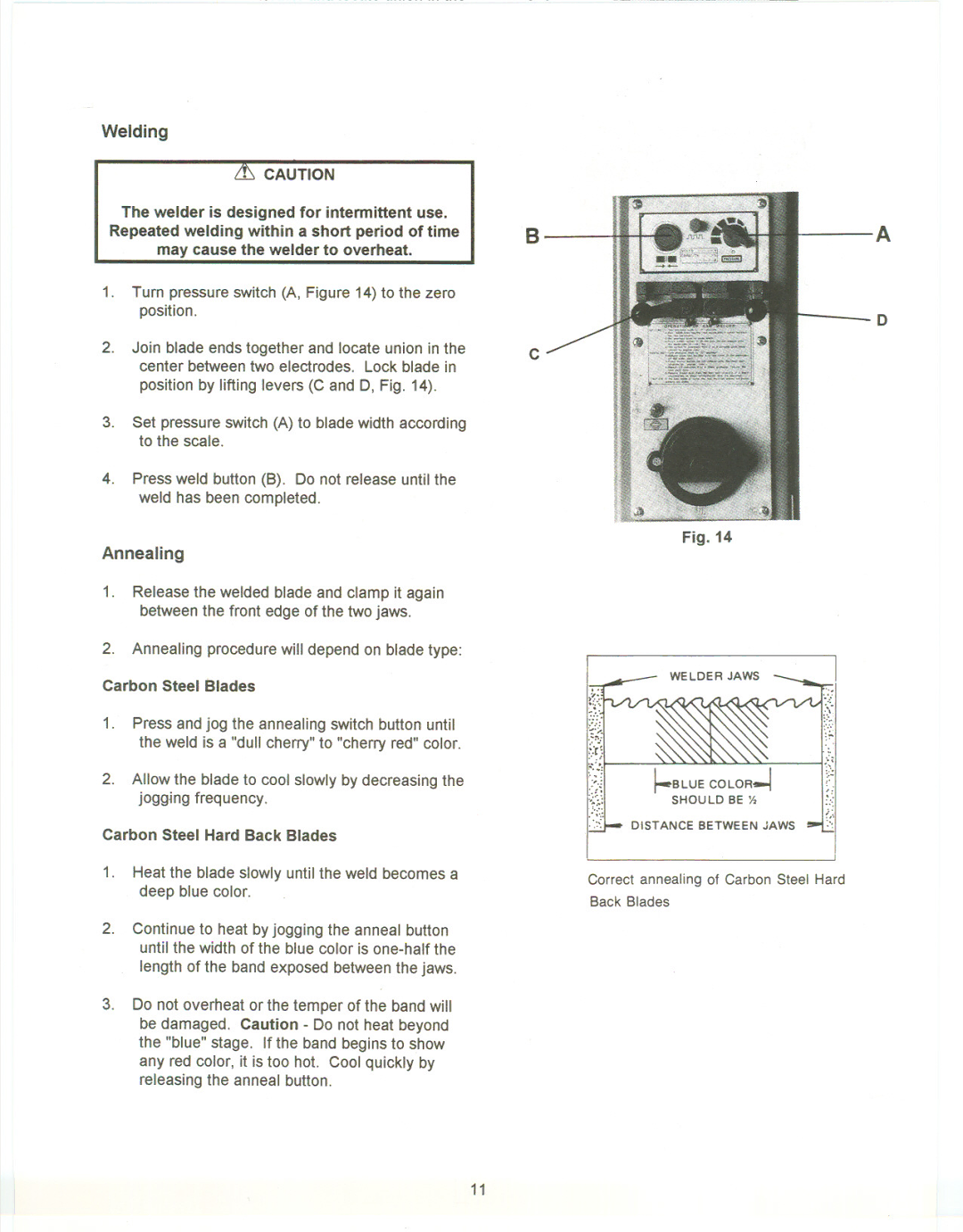

1.Turn pressure switch (A, Figure 14) to the zero position.

2.Join blade ends together and locate union in the center between two electrodes. Lockblade in

position by liftinglevers (C and D, Fig. 14).

3.Set pressure switch (A)to blade width according to the scale.

4.Press weld button (8). Do not release untilthe weld has been completed.

Annealing

1.Release the welded blade and clamp it again between the front edge of the twojaws.

2.Annealing procedure willdepend on blade type: Carbon Steel Blades

1.Press and jog the annealing switch button until the weld is a "dullcherry"to "cherry red" color.

2.Allowthe blade to cool slowlyby decreasing the jogg~ngfrequency.

Carbon Steel Hard Back Blades

1.Heat the blade slowlyuntilthe weld becomes a deep blue color.

2.Continue to heat byjogging the anneal button untilthe width of the blue color is

length of the band exposed between the jaws.

3.Do not overheat or the temper of the band will be damaged. Caution - Do not heat beyond the "blue"stage. Ifthe band begins to show

any red color, it is too hot. Cool quickly by releasing the anneal button.

BA

D

C

Fig. 14

.,

::::

DISTANCE BETWEEN JAWS :'.

Correct annealing of Carbon Steel Hard

Back Blades

11