BQ 048, BQ 036, BQ 060 specifications

Johnson Controls has established itself as a leading player in the HVAC and building management industries, and its BQ series of chillers - including the BQ 060, BQ 036, and BQ 048 - reflects this commitment to innovation and efficiency. These models are designed to provide advanced cooling solutions suitable for a variety of commercial applications.The BQ 060 is particularly notable for its high-performance capabilities. With a cooling capacity of 60 tons, it utilizes variable-speed compressors, allowing it to adjust its performance based on the cooling demand. This flexibility not only enhances energy efficiency but also reduces operational costs. The unit incorporates advanced microprocessor controls that facilitate seamless integration with building management systems, enabling real-time monitoring and adjustments.

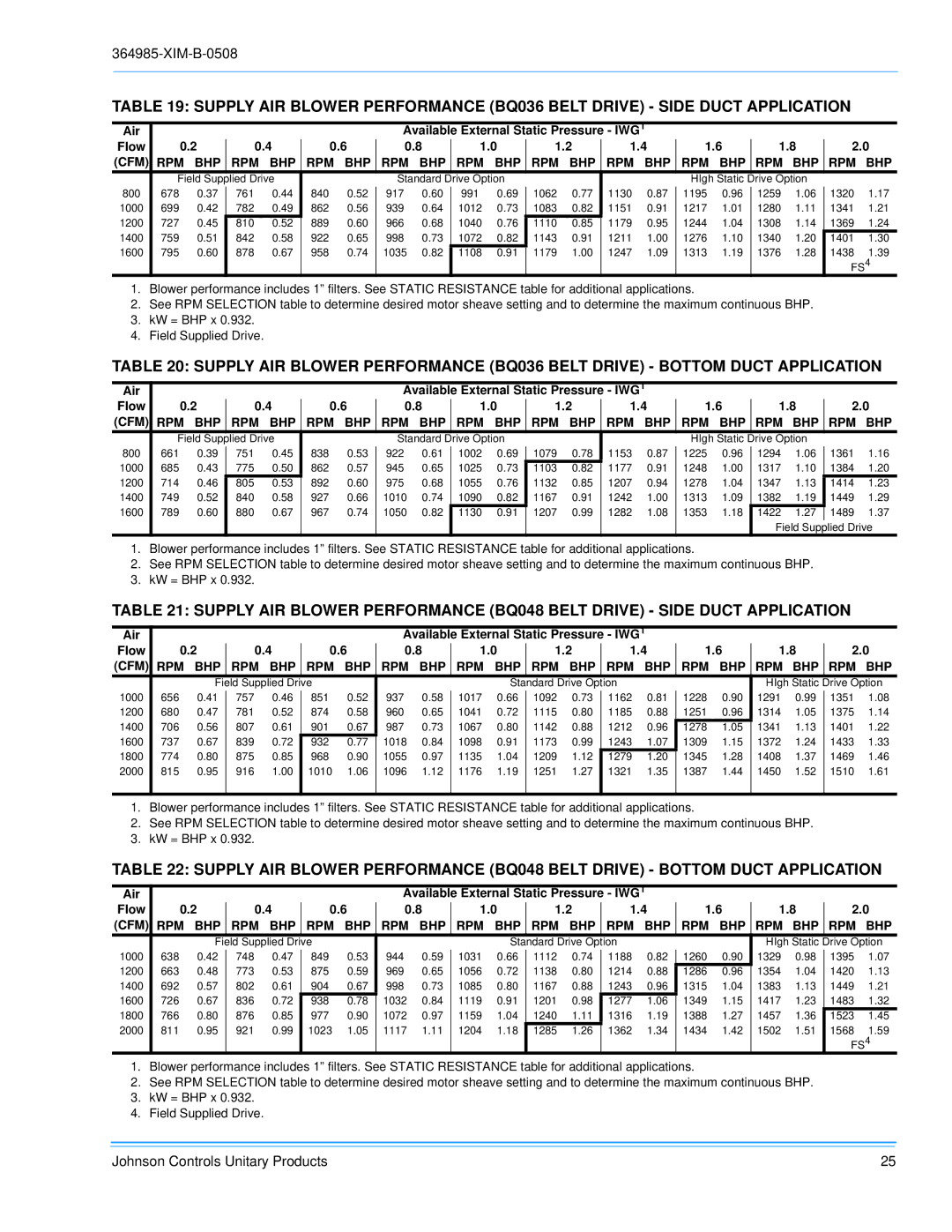

Moving on to the BQ 036, this model is engineered for facilities that require a smaller footprint but still demand reliability and efficiency. With a cooling capacity of 36 tons, it features a compact design without compromising on performance. The BQ 036 also employs environmentally friendly refrigerants, aligning with Johnson Controls' commitment to sustainability. Enhanced insulation and sound-dampening technologies make it an ideal choice for noise-sensitive environments, ensuring comfort without sacrificing efficiency.

The BQ 048 lies in between the two, with a capacity of 48 tons, making it versatile for medium-sized commercial buildings. Its design incorporates a modular approach, allowing for easy scalability in future expansions. This model also features energy recovery options that can utilize excess heat to improve overall efficiency, further solidifying its role in sustainable building practices. Its user-friendly interface enhances operability, simplifying management for building operators.

All three models of the BQ series share key characteristics, such as robust construction to withstand diverse environmental conditions, and low maintenance requirements thanks to their durable components. They utilize advanced technologies for temperature control and energy efficiency, including an intelligent controller that automates more routine tasks. Together, the BQ 060, BQ 036, and BQ 048 offer comprehensive solutions that cater to the growing demands of energy efficiency, sustainability, and reliability in modern building operations. With these chillers, Johnson Controls continues to lead the way in shaping the future of HVAC solutions.