SAFETY INSTRUCTIONS

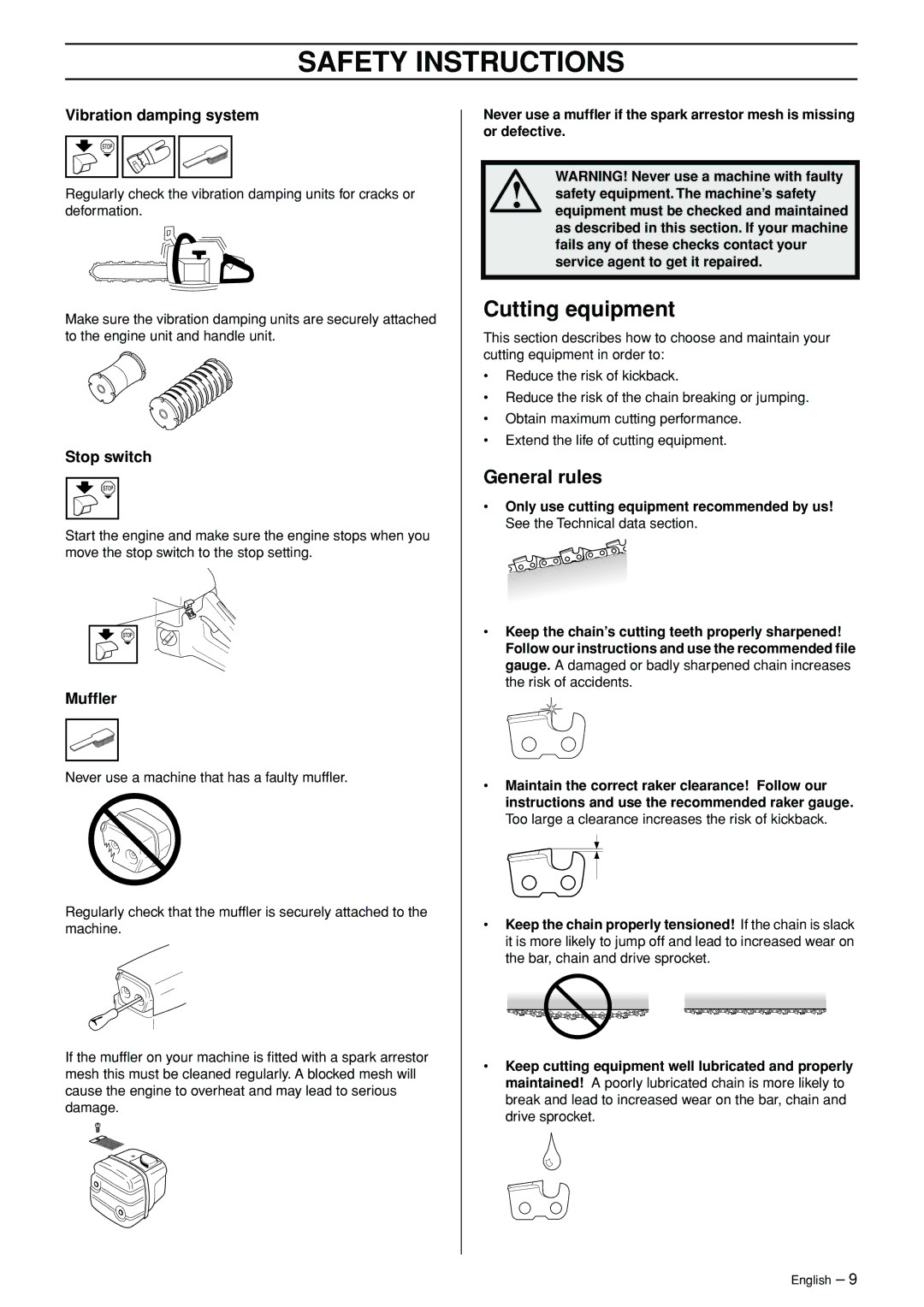

Vibration damping system

Regularly check the vibration damping units for cracks or deformation.

Make sure the vibration damping units are securely attached to the engine unit and handle unit.

Stop switch

Start the engine and make sure the engine stops when you move the stop switch to the stop setting.

Muffler

Never use a machine that has a faulty muffler.

Regularly check that the muffler is securely attached to the machine.

If the muffler on your machine is fitted with a spark arrestor mesh this must be cleaned regularly. A blocked mesh will cause the engine to overheat and may lead to serious damage.

Never use a muffler if the spark arrestor mesh is missing or defective.

WARNING! Never use a machine with faulty

!safety equipment. The machine’s safety equipment must be checked and maintained as described in this section. If your machine fails any of these checks contact your service agent to get it repaired.

Cutting equipment

This section describes how to choose and maintain your cutting equipment in order to:

•Reduce the risk of kickback.

•Reduce the risk of the chain breaking or jumping.

•Obtain maximum cutting performance.

•Extend the life of cutting equipment.

General rules

•Only use cutting equipment recommended by us! See the Technical data section.

•Keep the chain’s cutting teeth properly sharpened! Follow our instructions and use the recommended file gauge. A damaged or badly sharpened chain increases the risk of accidents.

•Maintain the correct raker clearance! Follow our instructions and use the recommended raker gauge. Too large a clearance increases the risk of kickback.

•Keep the chain properly tensioned! If the chain is slack it is more likely to jump off and lead to increased wear on the bar, chain and drive sprocket.

•Keep cutting equipment well lubricated and properly maintained! A poorly lubricated chain is more likely to break and lead to increased wear on the bar, chain and drive sprocket.

English – 9