SAFETY INSTRUCTIONS

Cutting equipment designed to minimise kickback

WARNING! Faulty cutting equipment or the

!wrong combination of bar and chain increases the risk of kickback! Use only the bar and chain combinations that we recommend. See the Technical data section.

The only way to avoid kickback is to make sure that the kickback zone of the bar never touches anything.

By using cutting equipment with

Bar

The smaller the tip radius the smaller the kickback zone and the lower the chance of kickback.

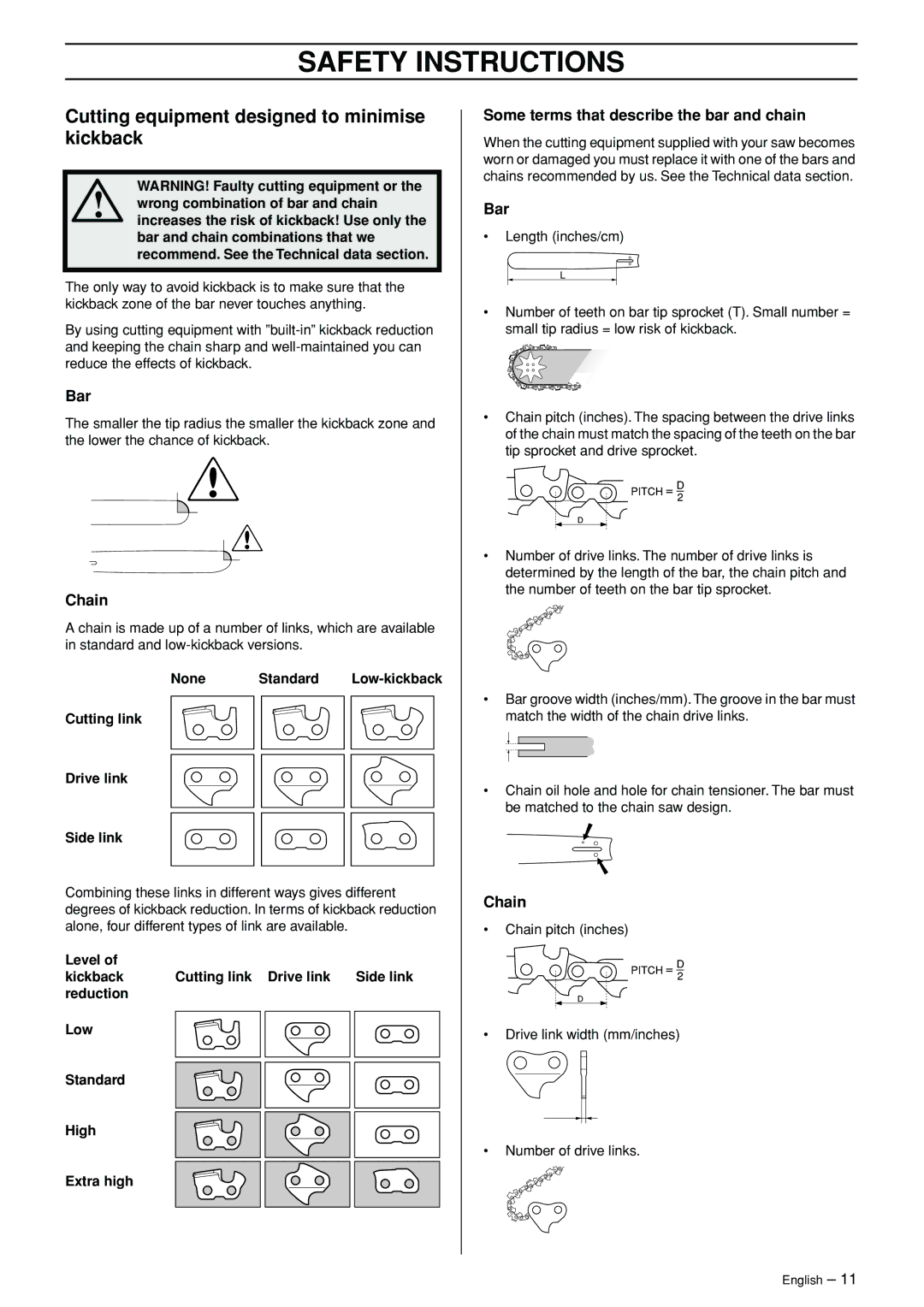

Chain

A chain is made up of a number of links, which are available in standard and

None | Standard |

Cutting link

Drive link

Side link

Combining these links in different ways gives different degrees of kickback reduction. In terms of kickback reduction alone, four different types of link are available.

Level of |

|

|

kickback | Cutting link Drive link | Side link |

reduction |

|

|

Low |

|

|

Standard |

|

|

High |

|

|

Extra high |

|

|

Some terms that describe the bar and chain

When the cutting equipment supplied with your saw becomes worn or damaged you must replace it with one of the bars and chains recommended by us. See the Technical data section.

Bar

•Length (inches/cm)

•Number of teeth on bar tip sprocket (T). Small number = small tip radius = low risk of kickback.

•Chain pitch (inches). The spacing between the drive links of the chain must match the spacing of the teeth on the bar tip sprocket and drive sprocket.

•Number of drive links. The number of drive links is determined by the length of the bar, the chain pitch and the number of teeth on the bar tip sprocket.

•Bar groove width (inches/mm). The groove in the bar must match the width of the chain drive links.

•Chain oil hole and hole for chain tensioner. The bar must be matched to the chain saw design.

Chain

•Chain pitch (inches)

•Drive link width (mm/inches)

•Number of drive links.

English – 11