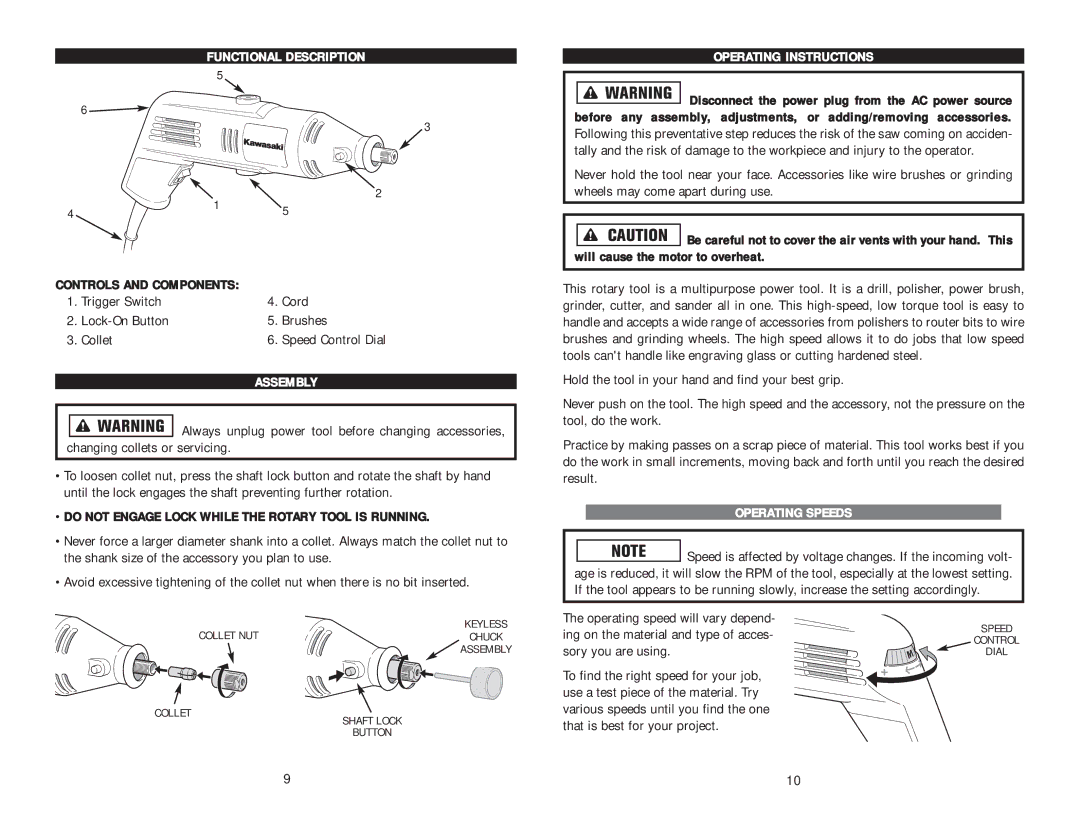

FUNCTIONAL DESCRIPTION

5

6 ![]()

3

| 1 | 2 | |

4 | 5 | ||

|

CONTROLS AND COMPONENTS: | 4. | Cord | |

1. | Trigger Switch | ||

2. | 5. | Brushes | |

3. | Collet | 6. | Speed Control Dial |

ASSEMBLY

![]()

![]()

![]()

![]()

![]()

![]()

![]() Always unplug power tool before changing accessories, changing collets or servicing.

Always unplug power tool before changing accessories, changing collets or servicing.

•To loosen collet nut, press the shaft lock button and rotate the shaft by hand until the lock engages the shaft preventing further rotation.

•DO NOT ENGAGE LOCK WHILE THE ROTARY TOOL IS RUNNING.

•Never force a larger diameter shank into a collet. Always match the collet nut to the shank size of the accessory you plan to use.

•Avoid excessive tightening of the collet nut when there is no bit inserted.

COLLET NUT | KEYLESS |

CHUCK | |

| ASSEMBLY |

COLLET

SHAFT LOCK

BUTTON

OPERATING INSTRUCTIONS

![]()

![]()

![]()

![]()

![]()

![]() Disconnect the power plug from the AC power source before any assembly, adjustments, or adding/removing accessories.

Disconnect the power plug from the AC power source before any assembly, adjustments, or adding/removing accessories.

Following this preventative step reduces the risk of the saw coming on acciden- tally and the risk of damage to the workpiece and injury to the operator.

Never hold the tool near your face. Accessories like wire brushes or grinding wheels may come apart during use.

![]()

![]()

![]()

![]()

![]()

![]()

![]() Be careful not to cover the air vents with your hand. This will cause the motor to overheat.

Be careful not to cover the air vents with your hand. This will cause the motor to overheat.

This rotary tool is a multipurpose power tool. It is a drill, polisher, power brush, grinder, cutter, and sander all in one. This

Hold the tool in your hand and find your best grip.

Never push on the tool. The high speed and the accessory, not the pressure on the tool, do the work.

Practice by making passes on a scrap piece of material. This tool works best if you do the work in small increments, moving back and forth until you reach the desired result.

OPERATING SPEEDS

![]()

![]()

![]()

![]() Speed is affected by voltage changes. If the incoming volt- age is reduced, it will slow the RPM of the tool, especially at the lowest setting. If the tool appears to be running slowly, increase the setting accordingly.

Speed is affected by voltage changes. If the incoming volt- age is reduced, it will slow the RPM of the tool, especially at the lowest setting. If the tool appears to be running slowly, increase the setting accordingly.

The operating speed will vary depend-

SPEED

ing on the material and type of acces- | CONTROL |

sory you are using. | DIAL |

To find the right speed for your job, use a test piece of the material. Try various speeds until you find the one that is best for your project.

9 | 10 |