•Just before the drill tip breaks though the other side of the work piece drill more slowly and decrease pressure on the tool. This will prevent stalling and leave a cleaner hole.

•Use a block of wood to back up work pieces that may splinter.

•Use spade bits when drilling large diameter holes in wood.

•Use HSS drill bits when drilling in metal.

•Use masonry bits when drilling in soft masonry.

•Use a lubricant when drilling metals other than cast iron, aluminum, copper, and brass.

•When drilling, start the hole slowly, allowing the bit to drill deep enough to prevent slipping at higher speeds.

•Never try to start a stalled Drill by clicking the trigger switch “ON” and “OFF”. This may damage your tool.

•To reduce jamming, always keep the Drill running when pulling the bit out of a finished hole.

SCREWDRIVING:

•Always use the correct type and size of screwdriver bit.

•If screws are difficult to tighten, try applying a small amount of washing liquid or soap as a lubricant.

•Always hold the tool and screwdriver bit in a straight line with the screw.

MAINTENANCE AND CLEANING

![]() Always remove the battery pack before attempting cleaning or maintenance.

Always remove the battery pack before attempting cleaning or maintenance.

![]()

![]()

![]()

![]() This Cordless Drill is lubricated before it leaves the factory. This lubrication should last for the life of the tool. No further lubrication is required.

This Cordless Drill is lubricated before it leaves the factory. This lubrication should last for the life of the tool. No further lubrication is required.

Use only mild soap and a damp cloth to clean the tool. Never let any liquid get inside the casing. Never immerse any part of the tool in a liquid. Always keep the ventilation openings clear.

Always clean the battery pack using only a dry cloth. Do not use liquids.

Always unplug the charger before cleaning it.

Regularly clean the ventilation slots in your tool and charger using only a soft brush or dry cloth.

Never open the Cordless Drill case, battery pack or charger. Do not attempt to repair the Cordless Drill, battery pack or charger yourself. Opening any of these parts will void your warranty.

ACCESSORIES

Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for one tool may become hazardous when used on another tool.

Always attach grounded

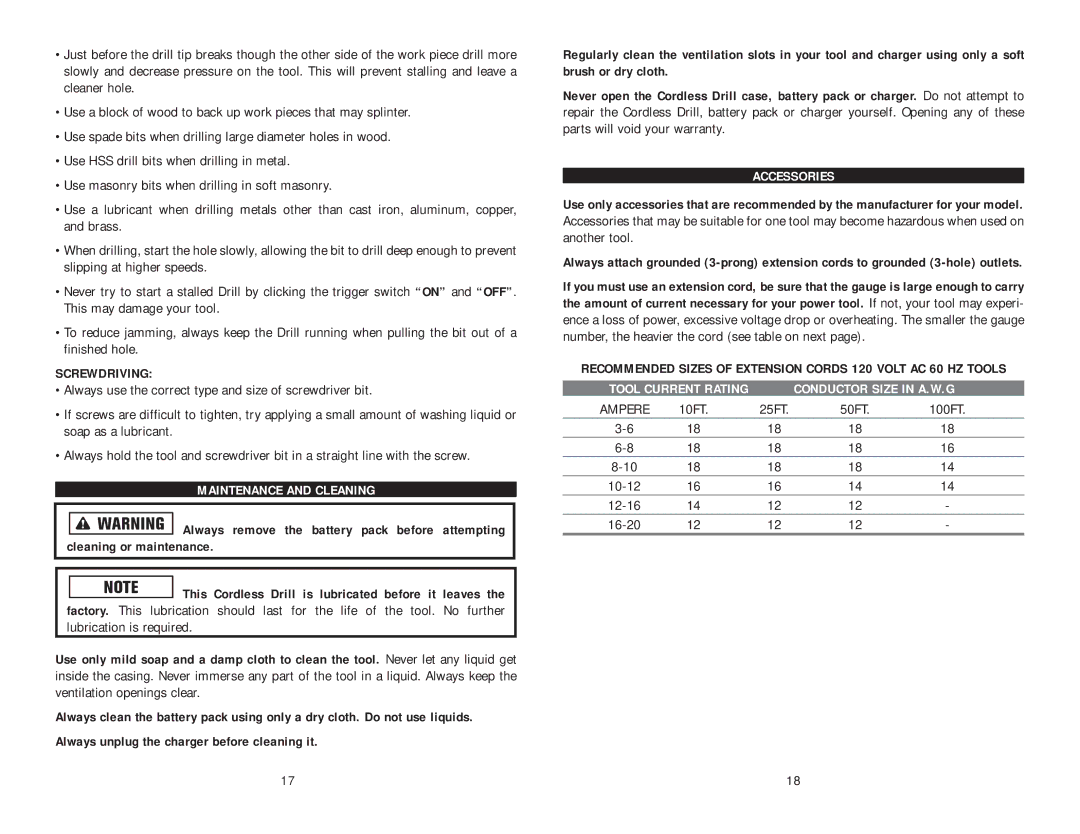

If you must use an extension cord, be sure that the gauge is large enough to carry the amount of current necessary for your power tool. If not, your tool may experi- ence a loss of power, excessive voltage drop or overheating. The smaller the gauge number, the heavier the cord (see table on next page).

RECOMMENDED SIZES OF EXTENSION CORDS 120 VOLT AC 60 HZ TOOLS

TOOL CURRENT RATING |

| CONDUCTOR SIZE IN A.W.G | ||

AMPERE | 10FT. | 25FT. | 50FT. | 100FT. |

18 | 18 | 18 | 18 | |

18 | 18 | 18 | 16 | |

18 | 18 | 18 | 14 | |

16 | 16 | 14 | 14 | |

14 | 12 | 12 | - | |

12 | 12 | 12 | - | |

17 | 18 |