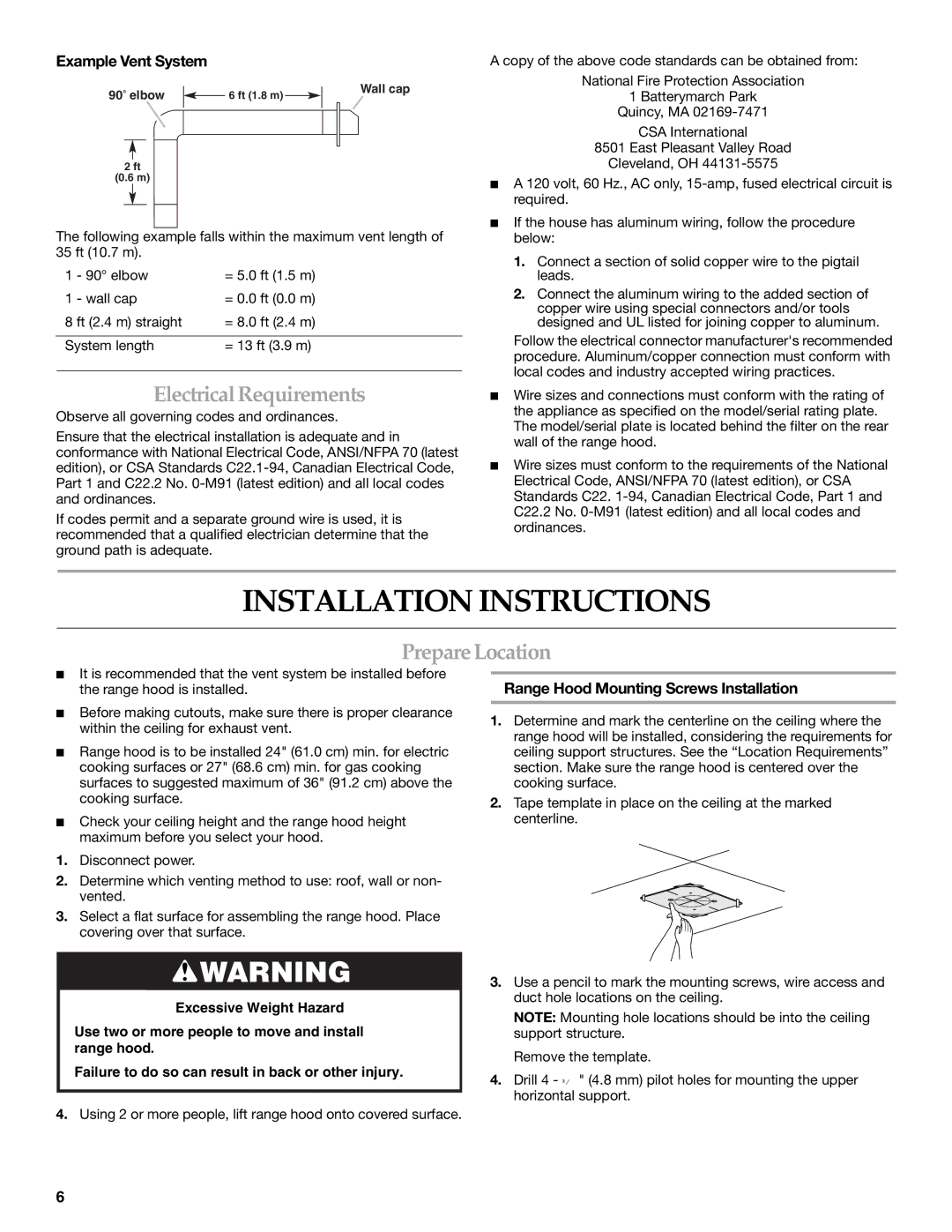

Example Vent System

90 elbow |

|

|

|

|

|

| Wall cap | ||||

|

| 6 ft (1.8 m) |

|

| |||||||

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2ft

(0.6 m)

The following example falls within the maximum vent length of 35 ft (10.7 m).

1 | - 90° elbow | = 5.0 ft (1.5 m) |

1 | - wall cap | = 0.0 ft (0.0 m) |

8 ft (2.4 m) straight | = 8.0 ft (2.4 m) | |

|

| |

System length | = 13 ft (3.9 m) | |

Electrical Requirements

Observe all governing codes and ordinances.

Ensure that the electrical installation is adequate and in conformance with National Electrical Code, ANSI/NFPA 70 (latest edition), or CSA Standards

If codes permit and a separate ground wire is used, it is recommended that a qualified electrician determine that the ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA

CSA International

8501 East Pleasant Valley Road

Cleveland, OH

■A 120 volt, 60 Hz., AC only,

■If the house has aluminum wiring, follow the procedure below:

1.Connect a section of solid copper wire to the pigtail leads.

2.Connect the aluminum wiring to the added section of copper wire using special connectors and/or tools designed and UL listed for joining copper to aluminum.

Follow the electrical connector manufacturer's recommended procedure. Aluminum/copper connection must conform with local codes and industry accepted wiring practices.

■Wire sizes and connections must conform with the rating of the appliance as specified on the model/serial rating plate. The model/serial plate is located behind the filter on the rear wall of the range hood.

■Wire sizes must conform to the requirements of the National Electrical Code, ANSI/NFPA 70 (latest edition), or CSA Standards C22.

INSTALLATION INSTRUCTIONS

Prepare Location

■It is recommended that the vent system be installed before the range hood is installed.

■Before making cutouts, make sure there is proper clearance within the ceiling for exhaust vent.

■Range hood is to be installed 24" (61.0 cm) min. for electric cooking surfaces or 27" (68.6 cm) min. for gas cooking surfaces to suggested maximum of 36" (91.2 cm) above the cooking surface.

■Check your ceiling height and the range hood height maximum before you select your hood.

1.Disconnect power.

2.Determine which venting method to use: roof, wall or non- vented.

3.Select a flat surface for assembling the range hood. Place covering over that surface.

WARNING

Excessive Weight Hazard

Use two or more people to move and install range hood.

Failure to do so can result in back or other injury.

4.Using 2 or more people, lift range hood onto covered surface.

Range Hood Mounting Screws Installation

1.Determine and mark the centerline on the ceiling where the range hood will be installed, considering the requirements for ceiling support structures. See the “Location Requirements” section. Make sure the range hood is centered over the cooking surface.

2.Tape template in place on the ceiling at the marked centerline.

3.Use a pencil to mark the mounting screws, wire access and duct hole locations on the ceiling.

NOTE: Mounting hole locations should be into the ceiling support structure.

Remove the template.

4.Drill 4 - ³⁄₁₆" (4.8 mm) pilot holes for mounting the upper horizontal support.

6