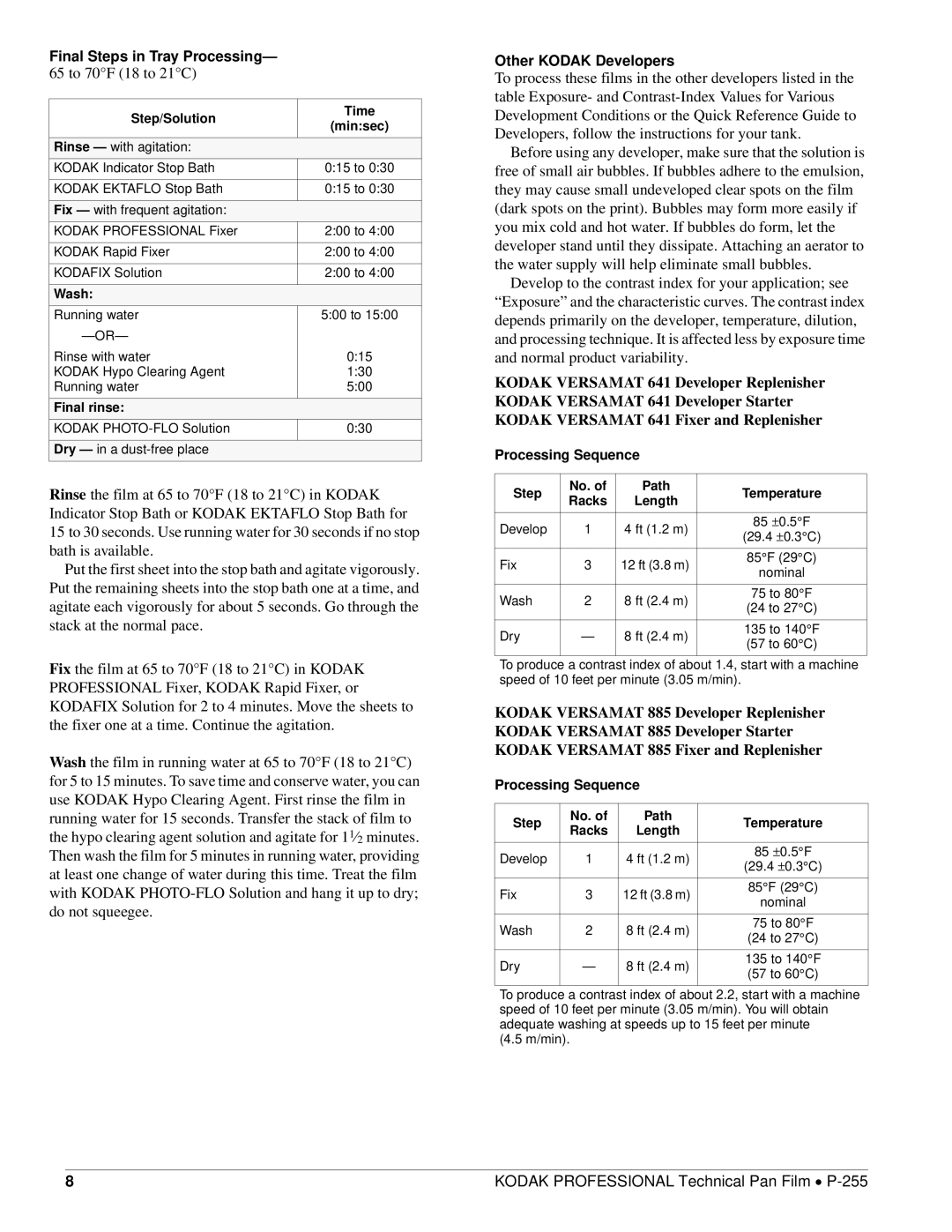

Final Steps in Tray Processing— 65 to 70°F (18 to 21°C)

Step/Solution | Time | |

(min:sec) | ||

| ||

|

| |

Rinse — with agitation: |

| |

|

|

KODAK Indicator Stop Bath | 0:15 to 0:30 |

|

|

KODAK EKTAFLO Stop Bath | 0:15 to 0:30 |

|

|

Fix — with frequent agitation: |

|

KODAK PROFESSIONAL Fixer | 2:00 to 4:00 |

|

|

KODAK Rapid Fixer | 2:00 to 4:00 |

|

|

KODAFIX Solution | 2:00 to 4:00 |

|

|

Wash: |

|

Running water | 5:00 to 15:00 |

| |

Rinse with water | 0:15 |

KODAK Hypo Clearing Agent | 1:30 |

Running water | 5:00 |

|

|

Final rinse: |

|

KODAK | 0:30 |

|

|

Dry — in a |

|

|

|

Rinse the film at 65 to 70°F (18 to 21°C) in KODAK Indicator Stop Bath or KODAK EKTAFLO Stop Bath for

15to 30 seconds. Use running water for 30 seconds if no stop bath is available.

Put the first sheet into the stop bath and agitate vigorously. Put the remaining sheets into the stop bath one at a time, and agitate each vigorously for about 5 seconds. Go through the stack at the normal pace.

Fix the film at 65 to 70°F (18 to 21°C) in KODAK PROFESSIONAL Fixer, KODAK Rapid Fixer, or KODAFIX Solution for 2 to 4 minutes. Move the sheets to the fixer one at a time. Continue the agitation.

Wash the film in running water at 65 to 70°F (18 to 21°C) for 5 to 15 minutes. To save time and conserve water, you can use KODAK Hypo Clearing Agent. First rinse the film in running water for 15 seconds. Transfer the stack of film to the hypo clearing agent solution and agitate for 11⁄2 minutes. Then wash the film for 5 minutes in running water, providing at least one change of water during this time. Treat the film with KODAK

Other KODAK Developers

To process these films in the other developers listed in the table Exposure- and

Before using any developer, make sure that the solution is free of small air bubbles. If bubbles adhere to the emulsion, they may cause small undeveloped clear spots on the film (dark spots on the print). Bubbles may form more easily if you mix cold and hot water. If bubbles do form, let the developer stand until they dissipate. Attaching an aerator to the water supply will help eliminate small bubbles.

Develop to the contrast index for your application; see

“Exposure” and the characteristic curves. The contrast index depends primarily on the developer, temperature, dilution, and processing technique. It is affected less by exposure time and normal product variability.

KODAK VERSAMAT 641 Developer Replenisher KODAK VERSAMAT 641 Developer Starter KODAK VERSAMAT 641 Fixer and Replenisher

Processing Sequence

Step | No. of | Path | Temperature | |

Racks | Length | |||

|

| |||

|

|

|

| |

Develop | 1 | 4 ft (1.2 m) | 85 ±0.5°F | |

(29.4 ±0.3°C) | ||||

|

|

| ||

|

|

|

| |

Fix | 3 | 12 ft (3.8 m) | 85°F (29°C) | |

nominal | ||||

|

|

| ||

|

|

|

| |

Wash | 2 | 8 ft (2.4 m) | 75 to 80°F | |

(24 to 27°C) | ||||

|

|

| ||

|

|

|

| |

Dry | — | 8 ft (2.4 m) | 135 to 140°F | |

(57 to 60°C) | ||||

|

|

| ||

|

|

|

|

To produce a contrast index of about 1.4, start with a machine speed of 10 feet per minute (3.05 m/min).

KODAK VERSAMAT 885 Developer Replenisher KODAK VERSAMAT 885 Developer Starter KODAK VERSAMAT 885 Fixer and Replenisher

Processing Sequence

Step | No. of | Path | Temperature | |

Racks | Length | |||

|

| |||

|

|

|

| |

Develop | 1 | 4 ft (1.2 m) | 85 ±0.5°F | |

(29.4 ±0.3°C) | ||||

|

|

| ||

|

|

|

| |

Fix | 3 | 12 ft (3.8 m) | 85°F (29°C) | |

nominal | ||||

|

|

| ||

|

|

|

| |

Wash | 2 | 8 ft (2.4 m) | 75 to 80°F | |

(24 to 27°C) | ||||

|

|

| ||

|

|

|

| |

Dry | — | 8 ft (2.4 m) | 135 to 140°F | |

(57 to 60°C) | ||||

|

|

| ||

|

|

|

|

To produce a contrast index of about 2.2, start with a machine speed of 10 feet per minute (3.05 m/min). You will obtain adequate washing at speeds up to 15 feet per minute

(4.5 m/min).

8 | KODAK PROFESSIONAL Technical Pan Film • |