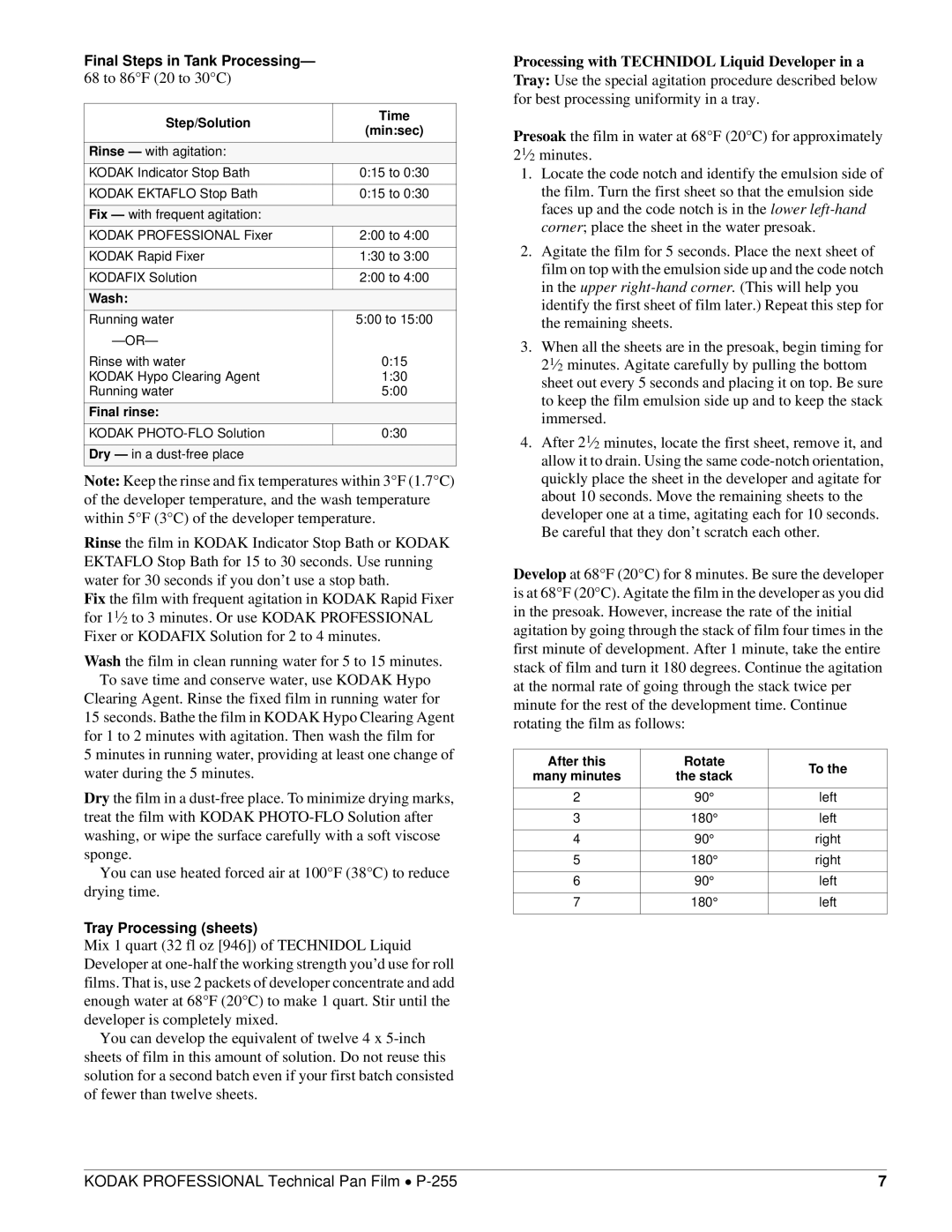

Final Steps in Tank Processing— 68 to 86°F (20 to 30°C)

Step/Solution | Time | |

(min:sec) | ||

| ||

|

| |

Rinse — with agitation: |

| |

|

|

KODAK Indicator Stop Bath | 0:15 to 0:30 |

|

|

KODAK EKTAFLO Stop Bath | 0:15 to 0:30 |

|

|

Fix — with frequent agitation: |

|

KODAK PROFESSIONAL Fixer | 2:00 to 4:00 |

|

|

KODAK Rapid Fixer | 1:30 to 3:00 |

|

|

KODAFIX Solution | 2:00 to 4:00 |

|

|

Wash: |

|

Running water | 5:00 to 15:00 |

| |

Rinse with water | 0:15 |

KODAK Hypo Clearing Agent | 1:30 |

Running water | 5:00 |

|

|

Final rinse: |

|

KODAK | 0:30 |

|

|

Dry — in a |

|

|

|

Note: Keep the rinse and fix temperatures within 3°F (1.7°C) of the developer temperature, and the wash temperature within 5°F (3°C) of the developer temperature.

Rinse the film in KODAK Indicator Stop Bath or KODAK EKTAFLO Stop Bath for 15 to 30 seconds. Use running water for 30 seconds if you don’t use a stop bath.

Fix the film with frequent agitation in KODAK Rapid Fixer for 11⁄2 to 3 minutes. Or use KODAK PROFESSIONAL Fixer or KODAFIX Solution for 2 to 4 minutes.

Wash the film in clean running water for 5 to 15 minutes. To save time and conserve water, use KODAK Hypo Clearing Agent. Rinse the fixed film in running water for

15seconds. Bathe the film in KODAK Hypo Clearing Agent for 1 to 2 minutes with agitation. Then wash the film for

5minutes in running water, providing at least one change of water during the 5 minutes.

Dry the film in a

You can use heated forced air at 100°F (38°C) to reduce drying time.

Tray Processing (sheets)

Mix 1 quart (32 fl oz [946]) of TECHNIDOL Liquid Developer at

You can develop the equivalent of twelve 4 x

Processing with TECHNIDOL Liquid Developer in a

Tray: Use the special agitation procedure described below for best processing uniformity in a tray.

Presoak the film in water at 68°F (20°C) for approximately 21⁄2 minutes.

1.Locate the code notch and identify the emulsion side of the film. Turn the first sheet so that the emulsion side faces up and the code notch is in the lower

2.Agitate the film for 5 seconds. Place the next sheet of film on top with the emulsion side up and the code notch in the upper

3.When all the sheets are in the presoak, begin timing for 21⁄2 minutes. Agitate carefully by pulling the bottom sheet out every 5 seconds and placing it on top. Be sure to keep the film emulsion side up and to keep the stack immersed.

4.After 21⁄2 minutes, locate the first sheet, remove it, and allow it to drain. Using the same

Develop at 68°F (20°C) for 8 minutes. Be sure the developer is at 68°F (20°C). Agitate the film in the developer as you did in the presoak. However, increase the rate of the initial agitation by going through the stack of film four times in the first minute of development. After 1 minute, take the entire stack of film and turn it 180 degrees. Continue the agitation at the normal rate of going through the stack twice per minute for the rest of the development time. Continue rotating the film as follows:

After this | Rotate | To the | |

many minutes | the stack | ||

| |||

|

|

| |

2 | 90° | left | |

|

|

| |

3 | 180° | left | |

|

|

| |

4 | 90° | right | |

|

|

| |

5 | 180° | right | |

|

|

| |

6 | 90° | left | |

|

|

| |

7 | 180° | left | |

|

|

|

KODAK PROFESSIONAL Technical Pan Film • | 7 |