KODAK DURAFLO RT Developer Replenisher

KODAK DURAFLO RT Developer Starter

KODAK Rapid Fixer

Processing Sequence

Step | No. of | Path | Temperature | |

Racks | Length | |||

|

| |||

|

|

|

| |

Develop | 1 | 8 ft (2.4 m) | 80 ±0.5°F | |

(27 ±0.3°C) | ||||

|

|

| ||

|

|

|

| |

Fix | 3 | 12 ft (3.8 m) | 80°F (27°C) | |

nominal | ||||

|

|

| ||

|

|

|

| |

Wash | 2 | 8 ft (2.4 m) | 70 to 75°F | |

(21 to 24°C) | ||||

|

|

| ||

|

|

|

| |

Dry | — | 8 ft (2.4 m) | 135 to 140°F* | |

(57 to 60°C) | ||||

|

|

| ||

|

|

|

|

To produce a contrast index of about 1.4, start with a machine speed of 8 feet per minute (2.4 m/min). Washing at this speed will not provide archival quality, but it should be adequate for many scientific recording applications.

*Use a lower dryer temperature (95 to 110°F or 35 to 44°C) with 2415 Film if spots form due to rapid drying. Lower temperatures may also be adequate if you are drying only roll film.

PRINTING

The 0.1 neutral density built into the

The

IMAGE-STRUCTURE CHARACTERISTICS

The data in this section are based on development at

68°F (20°C) in KODAK

| KODAK Developer | ||

|

|

| |

| TECHNIDOL Liquid | ||

Diffuse rms |

|

| |

8 Extremely fine | 5 Micro fine | ||

Granularity* | |||

|

| ||

*Read at a net diffuse density of 1.0 using a

|

|

|

|

|

|

| |||||

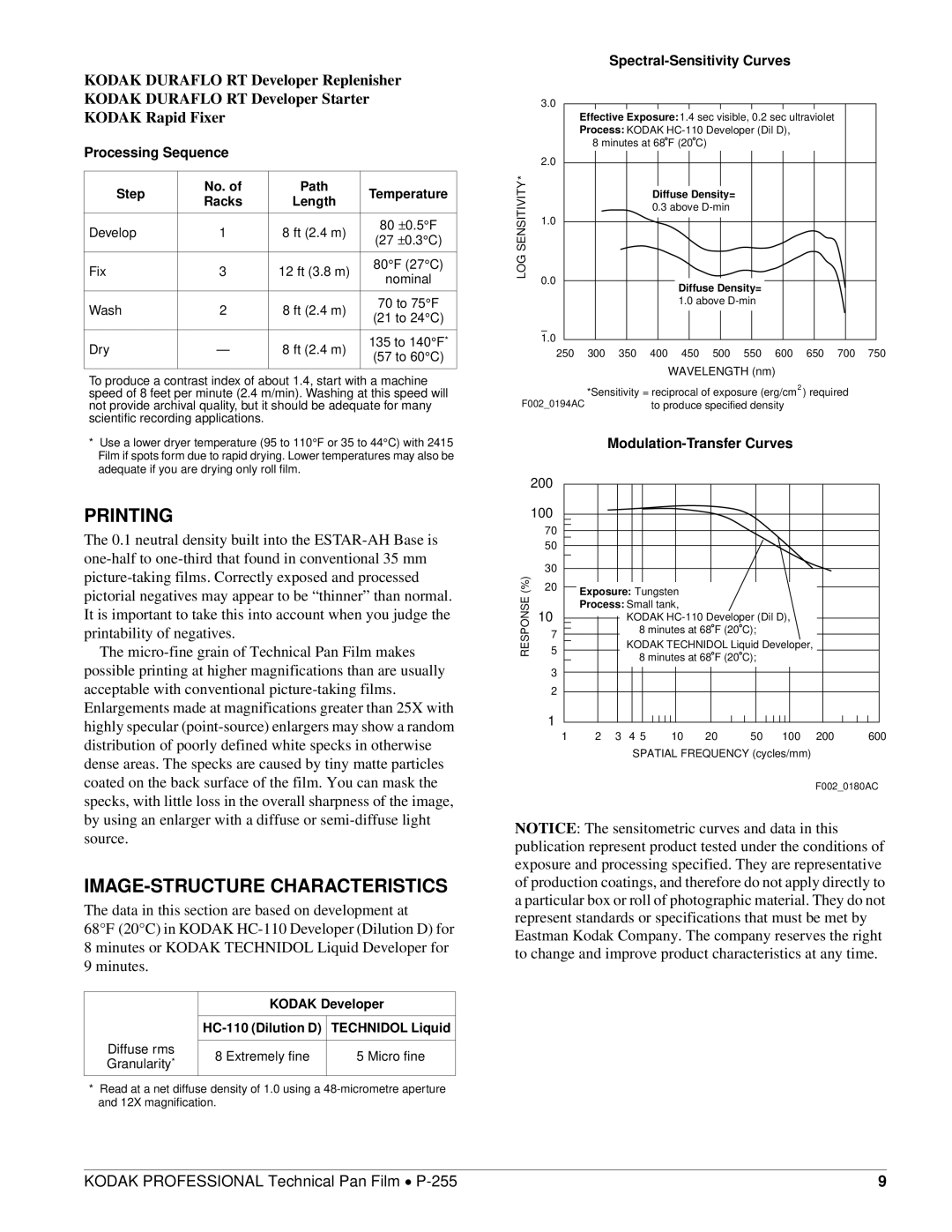

| 3.0 |

|

|

|

|

|

|

|

|

|

|

|

| Effective Exposure: 1.4 sec visible, 0.2 sec ultraviolet |

|

| |||||||

|

| Process: KODAK |

|

|

| ||||||

|

| 8 minutes at 68 F (20 C) |

|

|

|

|

|

| |||

| 2.0 |

|

|

|

|

|

|

|

|

|

|

* |

|

|

|

|

|

|

|

|

|

|

|

SENSITIVITYLOG |

|

|

| Diffuse Density= |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| |||

|

|

|

| 0.3 above |

|

|

|

|

| ||

| 1.0 |

|

|

|

|

|

|

|

|

|

|

| 0.0 |

|

|

| Diffuse Density= |

|

|

|

| ||

|

|

|

|

|

|

|

|

| |||

|

|

|

|

| 1.0 above |

|

|

|

| ||

| 1.0 |

|

|

|

|

|

|

|

|

|

|

| 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 |

WAVELENGTH (nm)

F002_0194AC | *Sensitivity = reciprocal of exposure (erg/cm2 ) required |

| |||||||||

|

|

| to produce specified density |

|

| ||||||

|

|

|

|

|

|

| |||||

| 200 |

|

|

|

|

|

|

|

|

|

|

| 100 |

|

|

|

|

|

|

|

|

|

|

| 70 |

|

|

|

|

|

|

|

|

|

|

| 50 |

|

|

|

|

|

|

|

|

|

|

(%) | 30 |

|

|

|

|

|

|

|

|

|

|

20 | Exposure: Tungsten |

|

|

|

|

| |||||

RESPONSE | 5 |

|

|

|

|

| |||||

Process: Small tank, |

|

|

|

|

| ||||||

| 10 |

|

|

|

|

| |||||

|

|

|

| KODAK |

|

| |||||

| 7 |

|

|

| 8 minutes at 68 F (20 C); |

|

|

| |||

|

|

|

| KODAK TECHNIDOL Liquid Developer, |

|

| |||||

|

|

|

|

|

|

| |||||

|

|

|

|

| 8 minutes at 68 F (20 C); |

|

|

| |||

| 3 |

|

|

|

|

|

|

|

|

|

|

| 2 |

|

|

|

|

|

|

|

|

|

|

| 1 |

|

|

|

|

|

|

|

|

|

|

|

| 1 | 2 | 3 | 4 5 | 10 | 20 | 50 | 100 | 200 | 600 |

|

|

|

|

| SPATIAL FREQUENCY (cycles/mm) |

|

| ||||

F002_0180AC

NOTICE: The sensitometric curves and data in this publication represent product tested under the conditions of exposure and processing specified. They are representative of production coatings, and therefore do not apply directly to a particular box or roll of photographic material. They do not represent standards or specifications that must be met by Eastman Kodak Company. The company reserves the right to change and improve product characteristics at any time.

KODAK PROFESSIONAL Technical Pan Film • | 9 |