Operating Check List

Hazard control and accident prevention are dependent upon the awareness, concern, prudence and proper training involved in the operation, transport, maintenance and storage of the blade. Therefore, It is absolutely essential that no one operates the rear blade without first having read, fully understood and become totally familiar with the Operator’s Manual. Make sure the operator has paid particular attention to:

•Important Safety Information, pages 1 to 4

•Section 1: Assembly & Set-up,page 7

•Section 2: Adjustments, page 8

•Section 3: Operating Procedures, page 9

•Section 4: Maintenance & Lubrication, page 10

Before beginning to operate your rear blade the following inspection should be performed

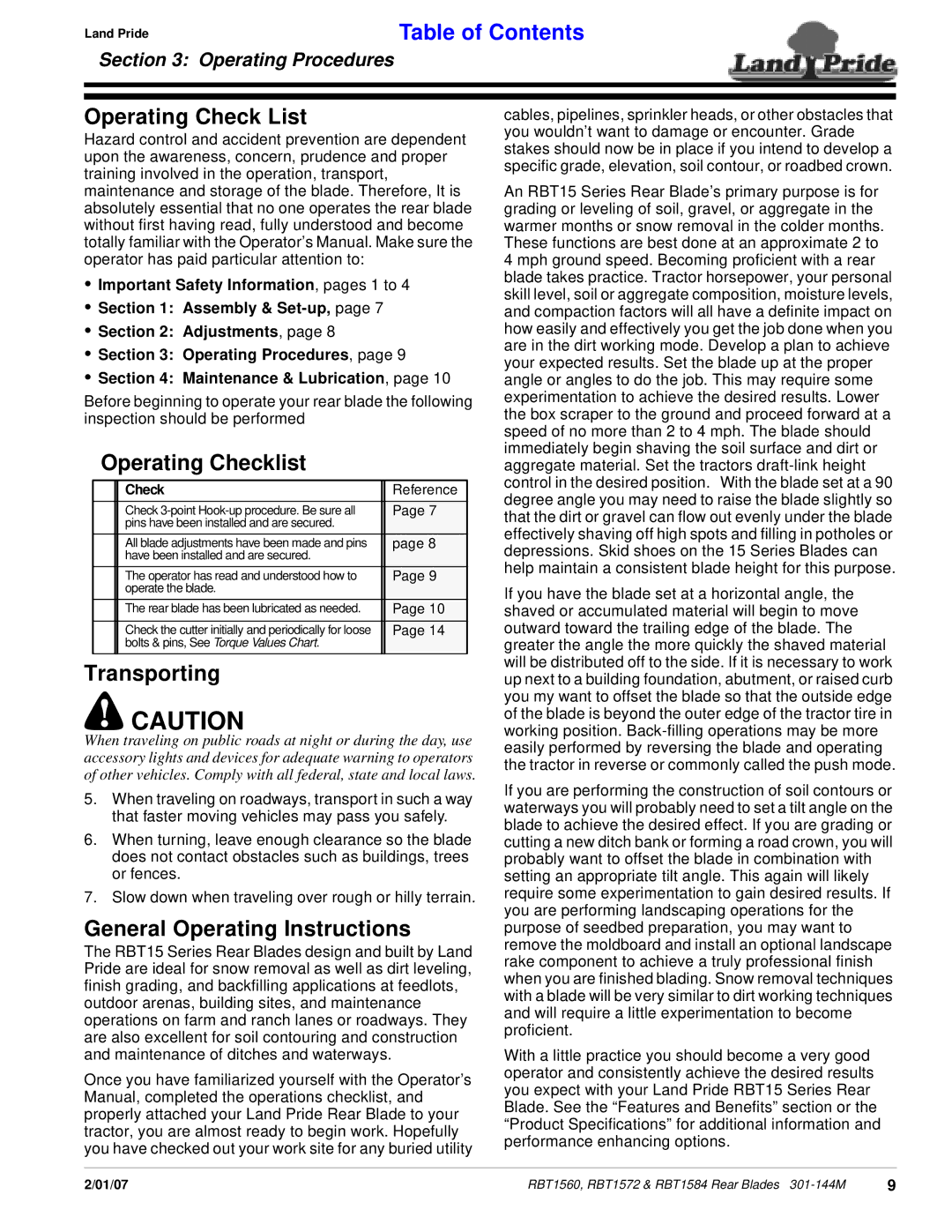

Operating Checklist

| ✔ | Check | Reference |

| | | |

| | Check 3-point Hook-up procedure. Be sure all | Page 7 |

| | pins have been installed and are secured. | |

| | All blade adjustments have been made and pins | page 8 |

| | have been installed and are secured. | |

| | The operator has read and understood how to | Page 9 |

| | operate the blade. | |

| | The rear blade has been lubricated as needed. | Page 10 |

| | Check the cutter initially and periodically for loose | Page 14 |

| | bolts & pins, See Torque Values Chart. | |

| | | |

Transporting | |

!CAUTION

When traveling on public roads at night or during the day, use accessory lights and devices for adequate warning to operators of other vehicles. Comply with all federal, state and local laws.

5.When traveling on roadways, transport in such a way that faster moving vehicles may pass you safely.

6.When turning, leave enough clearance so the blade does not contact obstacles such as buildings, trees or fences.

7.Slow down when traveling over rough or hilly terrain.

General Operating Instructions

The RBT15 Series Rear Blades design and built by Land Pride are ideal for snow removal as well as dirt leveling, finish grading, and backfilling applications at feedlots, outdoor arenas, building sites, and maintenance operations on farm and ranch lanes or roadways. They are also excellent for soil contouring and construction and maintenance of ditches and waterways.

Once you have familiarized yourself with the Operator’s Manual, completed the operations checklist, and properly attached your Land Pride Rear Blade to your tractor, you are almost ready to begin work. Hopefully you have checked out your work site for any buried utility

cables, pipelines, sprinkler heads, or other obstacles that you wouldn’t want to damage or encounter. Grade stakes should now be in place if you intend to develop a specific grade, elevation, soil contour, or roadbed crown.

An RBT15 Series Rear Blade’s primary purpose is for grading or leveling of soil, gravel, or aggregate in the warmer months or snow removal in the colder months. These functions are best done at an approximate 2 to 4 mph ground speed. Becoming proficient with a rear blade takes practice. Tractor horsepower, your personal skill level, soil or aggregate composition, moisture levels, and compaction factors will all have a definite impact on how easily and effectively you get the job done when you are in the dirt working mode. Develop a plan to achieve your expected results. Set the blade up at the proper angle or angles to do the job. This may require some experimentation to achieve the desired results. Lower the box scraper to the ground and proceed forward at a speed of no more than 2 to 4 mph. The blade should immediately begin shaving the soil surface and dirt or aggregate material. Set the tractors draft-link height control in the desired position. With the blade set at a 90 degree angle you may need to raise the blade slightly so that the dirt or gravel can flow out evenly under the blade effectively shaving off high spots and filling in potholes or depressions. Skid shoes on the 15 Series Blades can help maintain a consistent blade height for this purpose.

If you have the blade set at a horizontal angle, the shaved or accumulated material will begin to move outward toward the trailing edge of the blade. The greater the angle the more quickly the shaved material will be distributed off to the side. If it is necessary to work up next to a building foundation, abutment, or raised curb you my want to offset the blade so that the outside edge of the blade is beyond the outer edge of the tractor tire in working position. Back-filling operations may be more easily performed by reversing the blade and operating the tractor in reverse or commonly called the push mode.

If you are performing the construction of soil contours or waterways you will probably need to set a tilt angle on the blade to achieve the desired effect. If you are grading or cutting a new ditch bank or forming a road crown, you will probably want to offset the blade in combination with setting an appropriate tilt angle. This again will likely require some experimentation to gain desired results. If you are performing landscaping operations for the purpose of seedbed preparation, you may want to remove the moldboard and install an optional landscape rake component to achieve a truly professional finish when you are finished blading. Snow removal techniques with a blade will be very similar to dirt working techniques and will require a little experimentation to become proficient.

With a little practice you should become a very good operator and consistently achieve the desired results you expect with your Land Pride RBT15 Series Rear Blade. See the “Features and Benefits” section or the “Product Specifications” for additional information and performance enhancing options.