Land Pride

Section 4 Maintenance and Lubrication

Maintenance

Proper servicing and adjustment can increase the life of any implement. With careful and systematic inspection, you can avoid costly maintenance, time and repair.

1.After using your seeder for several hours, check all bolts to be sure they are tight.

2.After transporting your seeder for several hours, check all wheel lugs, bolts and nuts to be sure they are tight. Always maintain proper air pressure in the tires.

Storage

1.At the end of the working season or when your Pulverizer Seeder will not be used for a long period, it is good practice to clean off any dirt or grease that may have accumulated on the seeder and any of the moving parts.

2.Be sure that the seedbox is completely cleaned before storing.

3.The square bore of the feed cup drive sprocket hub should be oiled to prevent seizing. Squirt oil on to the square feed cup shaft and move feed cup adjustment lever back and forth in order to get the oil back into the square.

4.Lubricate all fittings as indicated.

5.When in storage, lower the seeder with rollers on a board or hard surface and adjust gauge wheels.

6.Repaint parts where paint is worn or scratched to prevent rust.

7.Replace all damaged or missing decals.

8.Store the seeder inside if possible. Inside storage will reduce maintenance and make for a longer seeder life.

9.Inspect the pulverizer seeder for loose, damaged or worn parts and adjust or replace if needed.

Lubrication

Lubrication

Legend

50 | ||||

spray lube | grease lube | oil lube | ||

|

Intervals at which lubrication is required

18531 |

![]()

![]() 50

50

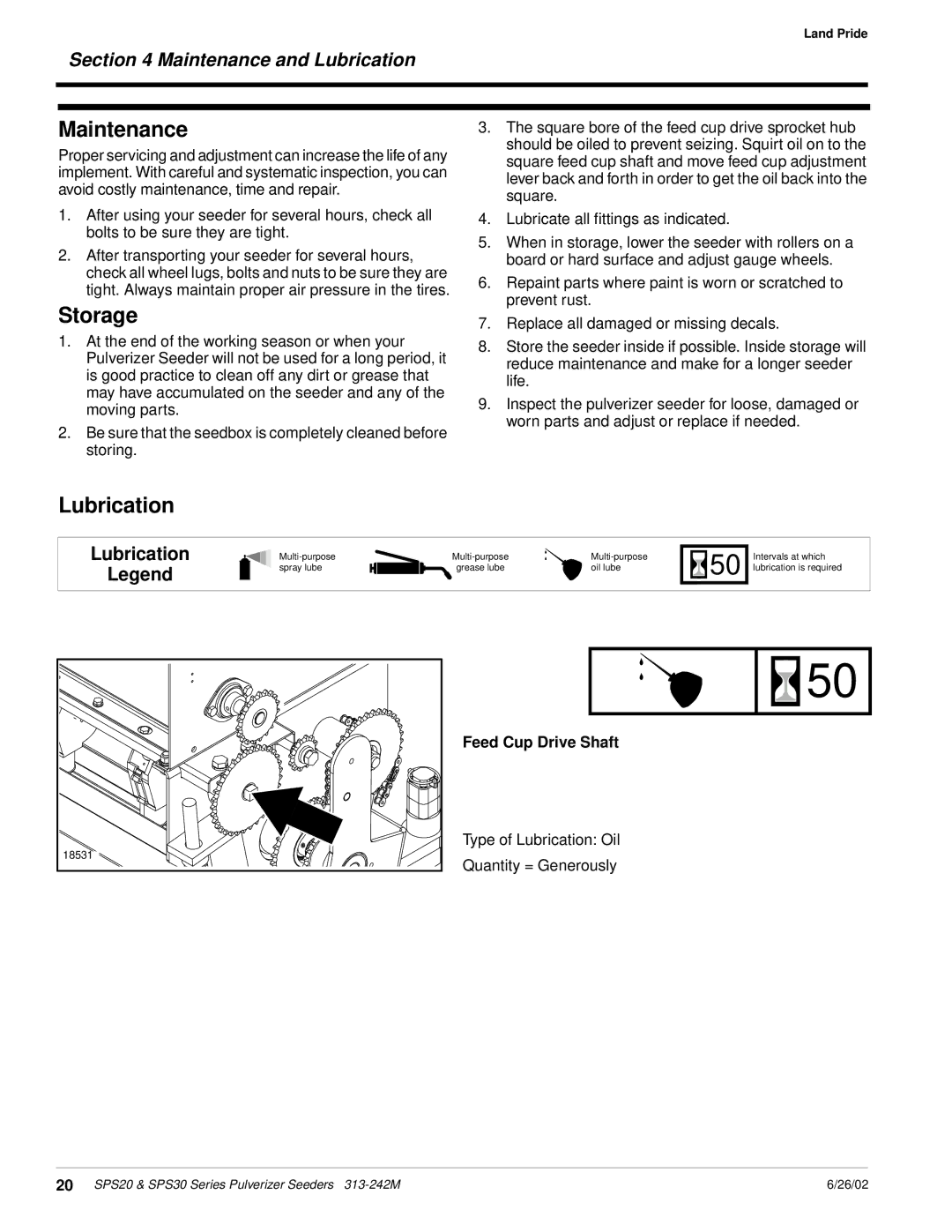

Feed Cup Drive Shaft

Type of Lubrication: Oil

Quantity = Generously

20 SPS20 & SPS30 Series Pulverizer Seeders | 6/26/02 |