EDA Unit Operation

The EDA coil is added to an HVAC system downstream of the indoor coil. In dehumidification mode, the coil becomes an extension of the condenser coil and injects heat into the indoor air stream.

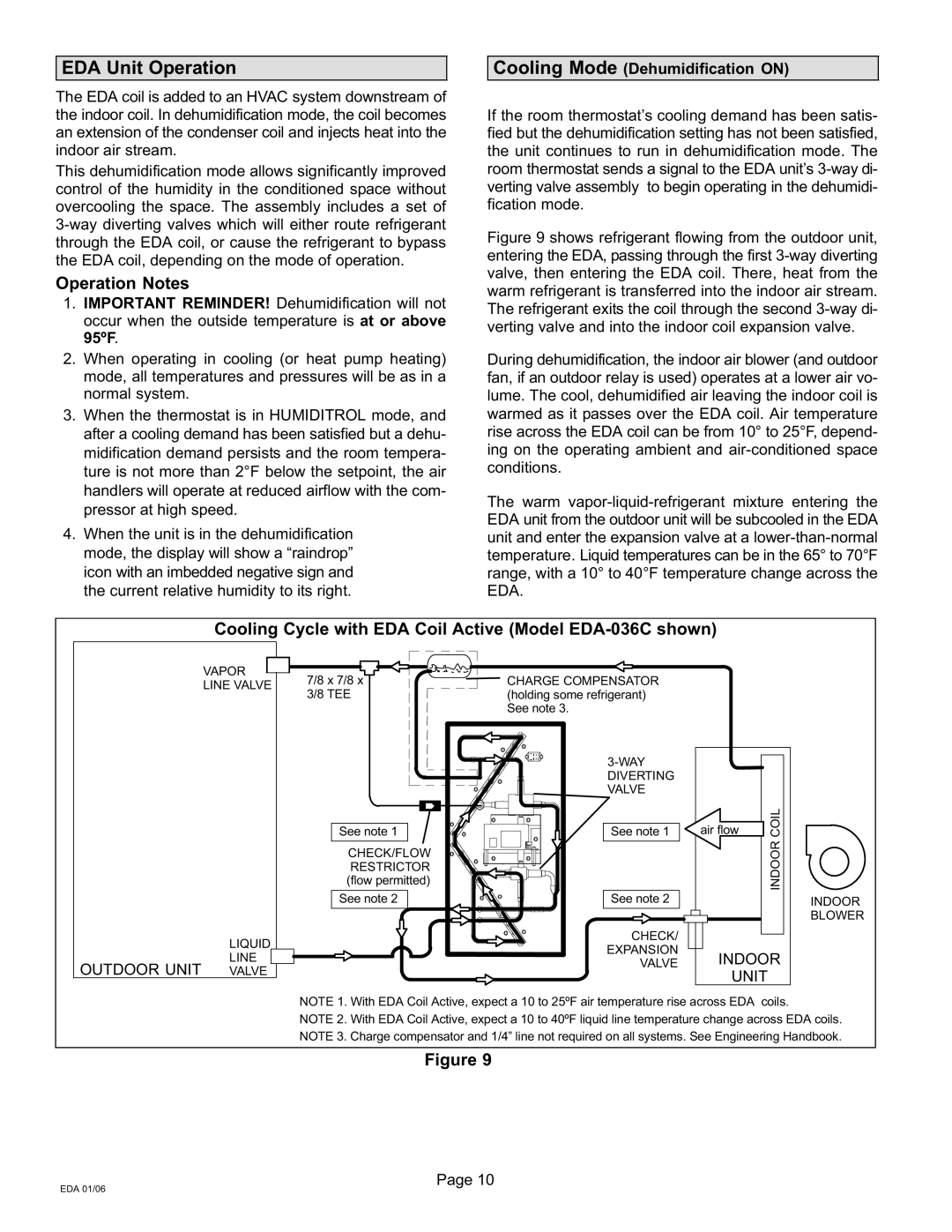

This dehumidification mode allows significantly improved control of the humidity in the conditioned space without overcooling the space. The assembly includes a set of 3−way diverting valves which will either route refrigerant through the EDA coil, or cause the refrigerant to bypass the EDA coil, depending on the mode of operation.

Operation Notes

1.IMPORTANT REMINDER! Dehumidification will not occur when the outside temperature is at or above 95ºF.

2.When operating in cooling (or heat pump heating) mode, all temperatures and pressures will be as in a normal system.

3.When the thermostat is in HUMIDITROL mode, and after a cooling demand has been satisfied but a dehu- midification demand persists and the room tempera- ture is not more than 2°F below the setpoint, the air handlers will operate at reduced airflow with the com- pressor at high speed.

4.When the unit is in the dehumidification mode, the display will show a

icon with an imbedded negative sign and the current relative humidity to its right.

Cooling Mode (Dehumidification ON)

If the room thermostat’s cooling demand has been satis- fied but the dehumidification setting has not been satisfied, the unit continues to run in dehumidification mode. The room thermostat sends a signal to the EDA unit’s 3−way di- verting valve assembly to begin operating in the dehumidi- fication mode.

Figure 9 shows refrigerant flowing from the outdoor unit, entering the EDA, passing through the first 3−way diverting valve, then entering the EDA coil. There, heat from the warm refrigerant is transferred into the indoor air stream. The refrigerant exits the coil through the second 3−way di- verting valve and into the indoor coil expansion valve.

During dehumidification, the indoor air blower (and outdoor fan, if an outdoor relay is used) operates at a lower air vo- lume. The cool, dehumidified air leaving the indoor coil is warmed as it passes over the EDA coil. Air temperature rise across the EDA coil can be from 10° to 25°F, depend- ing on the operating ambient and air-conditioned space conditions.

The warm vapor−liquid−refrigerant mixture entering the EDA unit from the outdoor unit will be subcooled in the EDA unit and enter the expansion valve at a lower-than-normal temperature. Liquid temperatures can be in the 65° to 70°F range, with a 10° to 40°F temperature change across the EDA.

Cooling Cycle with EDA Coil Active (Model EDA−036C shown)

VAPOR

LINE VALVE 7/8 x 7/8 x 3/8 TEE

See note 1

CHECK/FLOW RESTRICTOR (flow permitted)

See note 2

LIQUID

LINE

OUTDOOR UNIT VALVE

CHARGE COMPENSATOR (holding some refrigerant) See note 3.

3−WAY

DIVERTING VALVE

See note 1

See note 2

CHECK/

EXPANSION

VALVE

air flow | COIL |

| INDOOR |

|

|

INDOOR

UNIT

INDOOR BLOWER

NOTE 1. With EDA Coil Active, expect a 10 to 25ºF air temperature rise across EDA coils.

NOTE 2. With EDA Coil Active, expect a 10 to 40ºF liquid line temperature change across EDA coils.

NOTE 3. Charge compensator and 1/4" line not required on all systems. See Engineering Handbook.

Figure 9

Page 10

EDA 01/06