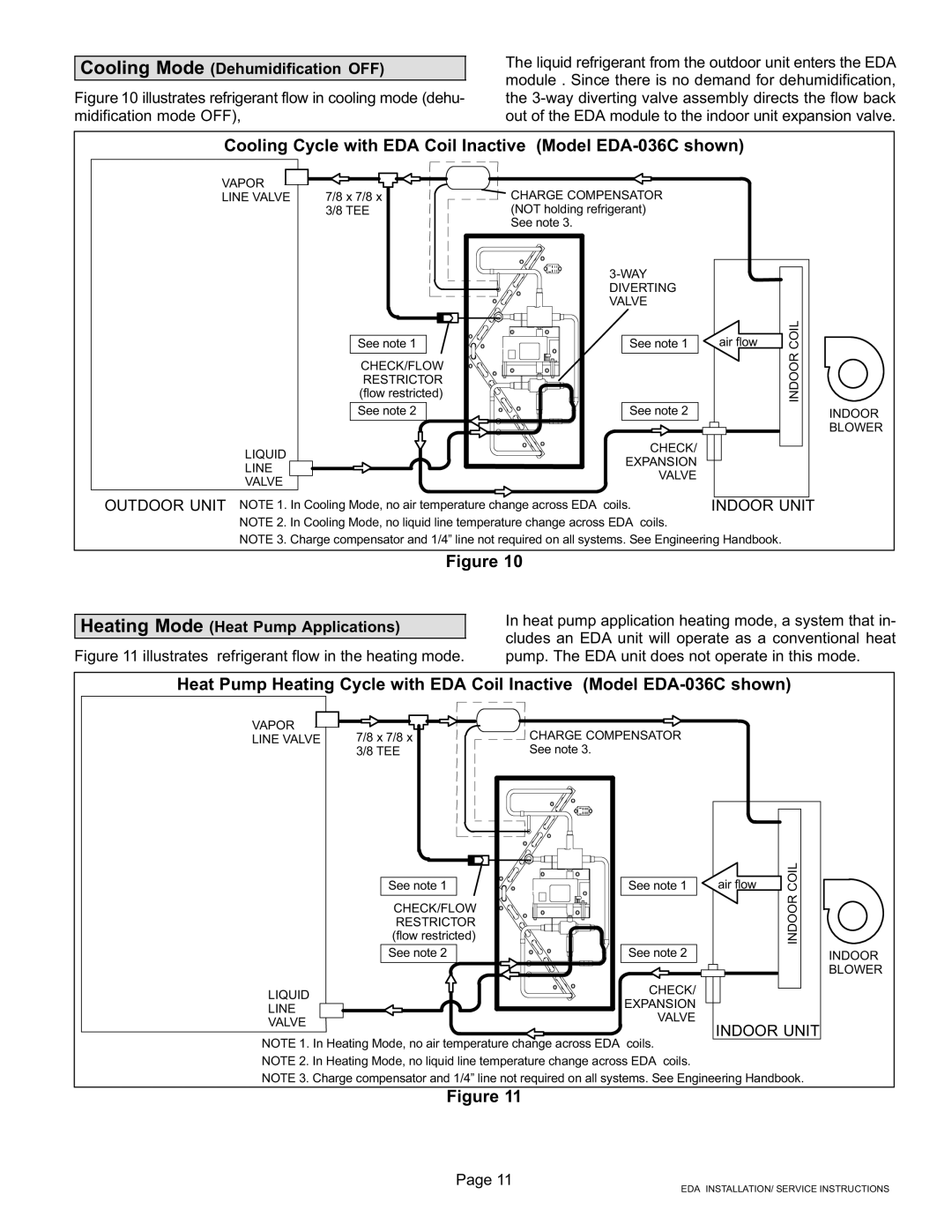

Cooling Mode (Dehumidification OFF)

Figure 10 illustrates refrigerant flow in cooling mode (dehu- midification mode OFF),

The liquid refrigerant from the outdoor unit enters the EDA module . Since there is no demand for dehumidification, the 3−way diverting valve assembly directs the flow back out of the EDA module to the indoor unit expansion valve.

Cooling Cycle with EDA Coil Inactive (Model EDA−036C shown)

VAPOR

LINE VALVE 7/8 x 7/8 x 3/8 TEE

See note 1

CHECK/FLOW RESTRICTOR (flow restricted)

See note 2

LIQUID

LINE

VALVE

CHARGE COMPENSATOR (NOT holding refrigerant) See note 3.

3−WAY

DIVERTING VALVE

See note 1

See note 2

CHECK/

EXPANSION

VALVE

air flow | COIL |

| INDOOR |

INDOOR BLOWER

OUTDOOR UNIT NOTE 1. In Cooling Mode, no air temperature change across EDA coils. NOTE 2. In Cooling Mode, no liquid line temperature change across EDA coils.

INDOOR UNIT

NOTE 3. Charge compensator and 1/4" line not required on all systems. See Engineering Handbook.

Figure 10

Heating Mode (Heat Pump Applications)

Figure 11 illustrates refrigerant flow in the heating mode.

In heat pump application heating mode, a system that in- cludes an EDA unit will operate as a conventional heat pump. The EDA unit does not operate in this mode.

Heat Pump Heating Cycle with EDA Coil Inactive (Model EDA−036C shown)

VAPOR

LINE VALVE 7/8 x 7/8 x 3/8 TEE

See note 1

CHECK/FLOW RESTRICTOR (flow restricted)

See note 2

LIQUID

LINE

VALVE

CHARGE COMPENSATOR See note 3.

See note 1

See note 2

CHECK/

EXPANSION

VALVE

|

| COIL |

air flow | ||

|

| INDOOR |

|

|

|

INDOOR UNIT

INDOOR BLOWER

NOTE 1. In Heating Mode, no air temperature change across EDA coils. NOTE 2. In Heating Mode, no liquid line temperature change across EDA coils.

NOTE 3. Charge compensator and 1/4" line not required on all systems. See Engineering Handbook.

Figure 11

Page 11

EDA INSTALLATION/ SERVICE INSTRUCTIONS