TABLE 3. TORQUE REQUIREMENTS

Parts | Recommended Torque | |

|

|

|

Service valve cap | 8 ft.- lb. | 11 NM |

|

|

|

Sheet metal screws | 16 in.- lb. | 2 NM |

|

|

|

Machine screws #10 | 28 in.- lb. | 3 NM |

|

|

|

Compressor bolts | 90 in.- lb. | 10 NM |

|

|

|

Gauge port seal cap | 8 ft.- lb. | 11 NM |

|

|

|

gauge set that features low loss

Manifold gauge set used with

Using Manifold Gauge Set

When checking the system charge, only use a manifold

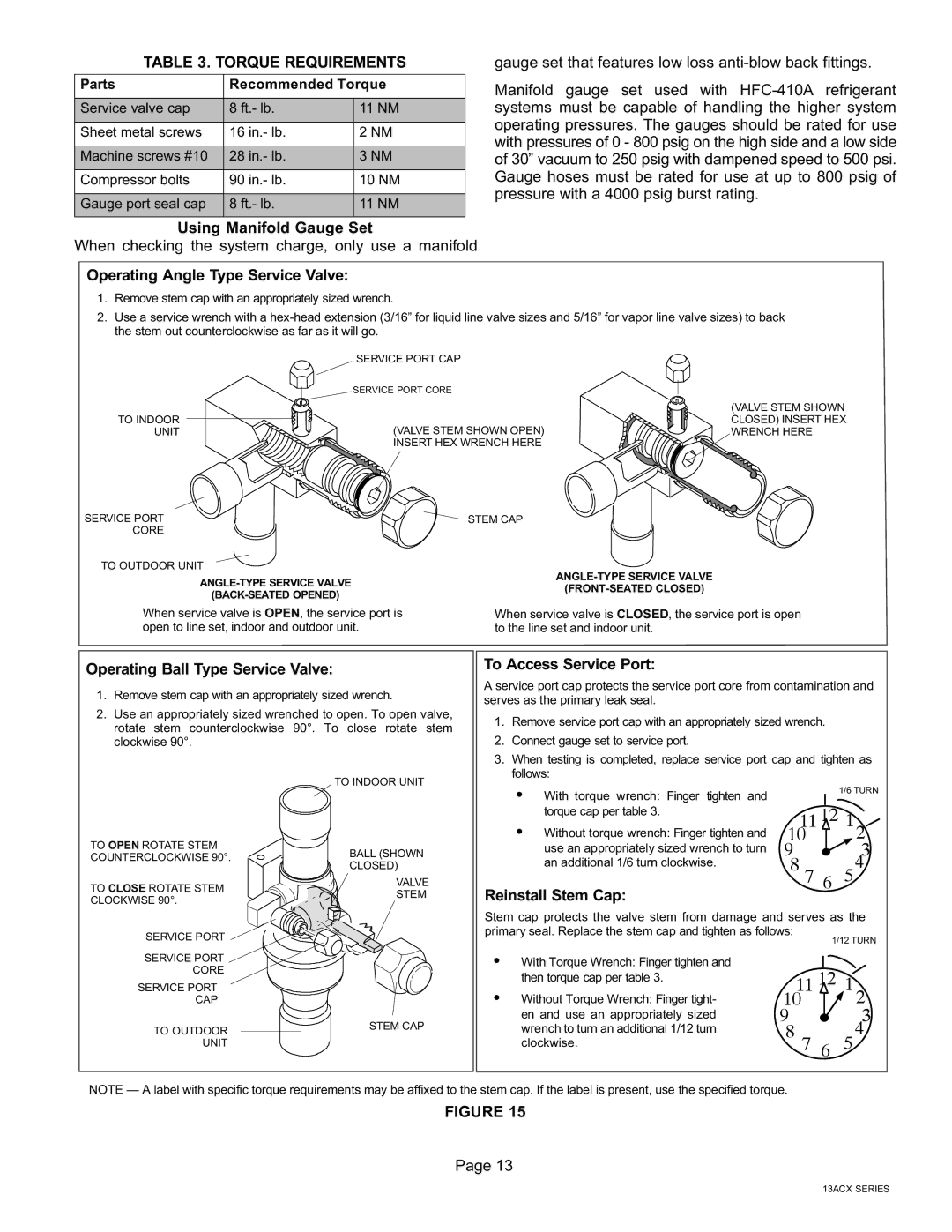

Operating Angle Type Service Valve:

1.Remove stem cap with an appropriately sized wrench.

2.Use a service wrench with a

SERVICE PORT CAP

SERVICE PORT CORE

TO INDOOR

UNIT

SERVICE PORT

CORE

TO OUTDOOR UNIT

(VALVE STEM SHOWN OPEN) INSERT HEX WRENCH HERE

STEM CAP

(VALVE STEM SHOWN CLOSED) INSERT HEX WRENCH HERE

When service valve is OPEN, the service port is open to line set, indoor and outdoor unit.

When service valve is CLOSED, the service port is open to the line set and indoor unit.

Operating Ball Type Service Valve:

1.Remove stem cap with an appropriately sized wrench.

2.Use an appropriately sized wrenched to open. To open valve, rotate stem counterclockwise 90°. To close rotate stem clockwise 90°.

To Access Service Port:

A service port cap protects the service port core from contamination and serves as the primary leak seal.

1.Remove service port cap with an appropriately sized wrench.

2.Connect gauge set to service port.

3.When testing is completed, replace service port cap and tighten as follows:

TO OPEN ROTATE STEM COUNTERCLOCKWISE 90°.

TO CLOSE ROTATE STEM CLOCKWISE 90°.

TO INDOOR UNIT

BALL (SHOWN CLOSED)

VALVE

STEM

SWith torque wrench: Finger tighten and torque cap per table 3.

SWithout torque wrench: Finger tighten and use an appropriately sized wrench to turn an additional 1/6 turn clockwise.

Reinstall Stem Cap:

1/6 TURN

11 12 1

10 2

98 7 6 543

SERVICE PORT ![]()

SERVICE PORT

CORE

SERVICE PORT

CAP

TO OUTDOOR

UNIT

STEM CAP

Stem cap protects the valve stem from damage and serves as the primary seal. Replace the stem cap and tighten as follows:

|

|

|

|

| 1/12 TURN | ||

S | With Torque Wrench: Finger tighten and |

|

|

|

|

|

|

|

|

|

|

|

| ||

| then torque cap per table 3. |

| 11 12 | 1 |

| ||

|

|

|

|

|

|

| |

S | Without Torque Wrench: Finger tight | 10 |

|

|

| 2 | |

|

|

| |||||

| en and use an appropriately sized | 9 |

|

|

|

| 3 |

|

|

|

|

| |||

| wrench to turn an additional 1/12 turn | 8 | 7 | 6 | 5 | 4 | |

|

|

| |||||

| clockwise. |

|

| ||||

|

|

|

|

|

|

| |

NOTE — A label with specific torque requirements may be affixed to the stem cap. If the label is present, use the specified torque.

FIGURE 15

Page 13

13ACX SERIES