STEP 2

Flush the existing line set per the following instructions. For more information, refer to the Installation and Service Procedures manual available on DaveNet. CAUTION - DO NOT attempt to flush and

NOTE - When installing refrigerant lines longer than 50 feet, refer to the Refrigerant Piping Design and Fabrication Guidelines manual available on DaveNet (Corp.

IMPORTANT !

If this unit is being matched with an approved line set or indoor unit coil that was previously charged with mineral oil, or if it is being matched with a coil which was manufactured before January of 1999, the coil and line set must be flushed prior to installation. Take care to empty all existing traps. Polyol ester (POE) oils are used in Lennox units charged with

Failure to properly flush the system per this instruc tion and the detailed Installation and Service Proce dures manual will void the warranty.

![]() WARNING

WARNING

![]() WARNING

WARNING

Polyol ester (POE) oils used with

IMPORTANT !

Some scroll compressors have an internal vacuum protector that will unload scrolls when suction pres sure goes below 20 psig. A hissing sound will be heard when the compressor is running unloaded. Protector will reset when low pressure in system is raised above 40 psig. DO NOT REPLACE COMPRES SOR.

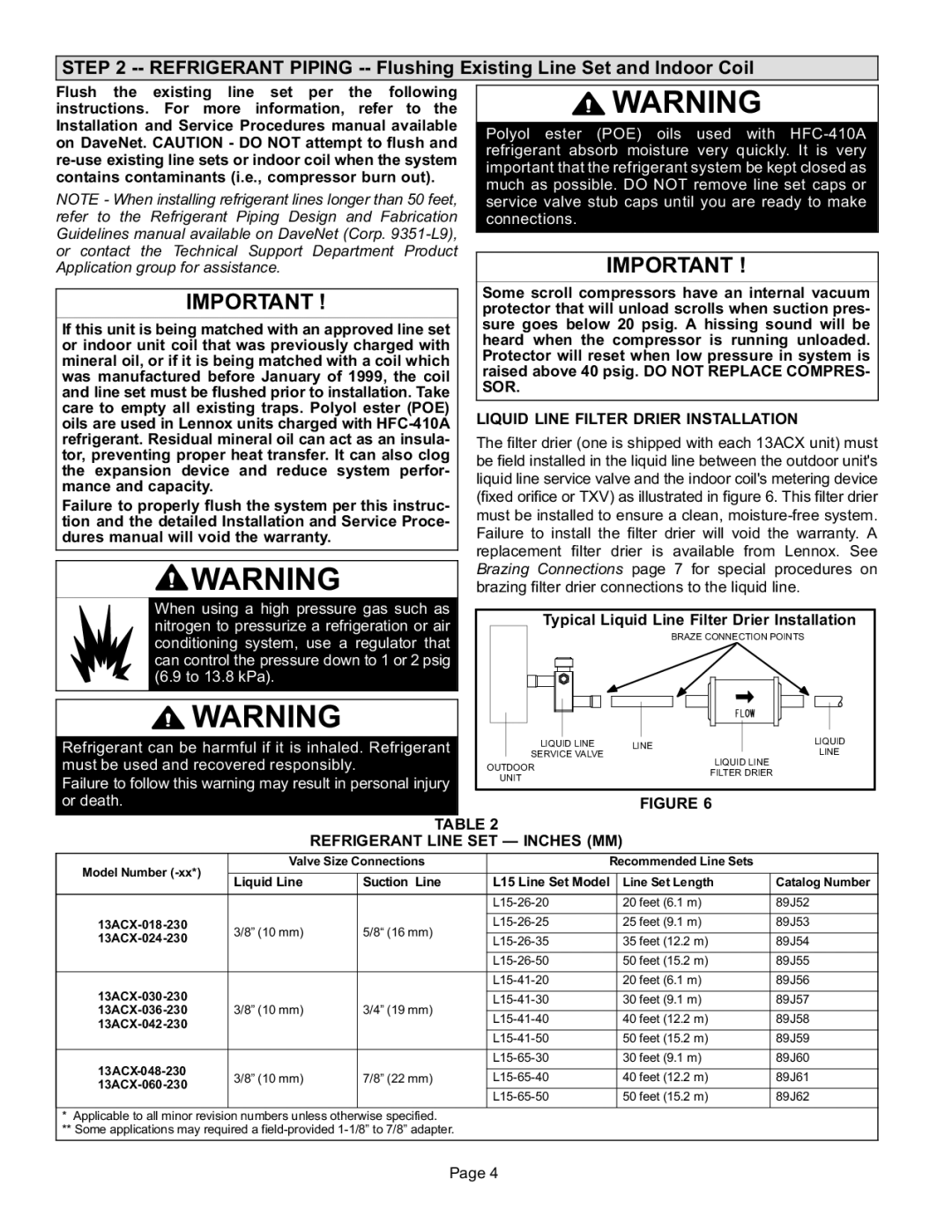

LIQUID LINE FILTER DRIER INSTALLATION

The filter drier (one is shipped with each 13ACX unit) must be field installed in the liquid line between the outdoor unit's liquid line service valve and the indoor coil's metering device (fixed orifice or TXV) as illustrated in figure 6. This filter drier must be installed to ensure a clean,

When using a high pressure gas such as |

|

| Typical Liquid Line Filter Drier Installation | ||

nitrogen to pressurize a refrigeration or air |

|

| |||

|

|

| BRAZE CONNECTION POINTS |

| |

conditioning system, use a regulator that |

|

|

|

| |

|

|

|

|

| |

can control the pressure down to 1 or 2 psig |

|

|

|

|

|

(6.9 to 13.8 kPa). |

|

|

|

|

|

WARNING |

|

|

|

|

|

Refrigerant can be harmful if it is inhaled. Refrigerant |

|

| LIQUID LINE | LINE | LIQUID |

|

| LINE | |||

|

| SERVICE VALVE |

| ||

must be used and recovered responsibly. |

| LIQUID LINE |

| ||

OUTDOOR |

|

| |||

| FILTER DRIER |

| |||

Failure to follow this warning may result in personal injury | UNIT |

|

|

| |

|

|

|

| ||

|

|

|

|

| |

or death. |

|

|

| FIGURE 6 |

|

TABLE 2

REFRIGERANT LINE SET — INCHES (MM)

Model Number | Valve Size Connections |

| Recommended Line Sets |

| ||

|

|

|

|

|

| |

| Liquid Line | Suction Line | L15 Line Set Model | Line Set Length | Catalog Number | |

|

|

|

|

|

|

|

|

|

|

| 20 feet (6.1 m) | 89J52 | |

|

|

|

|

|

|

|

3/8” (10 mm) | 5/8“ (16 mm) |

| 25 feet (9.1 m) | 89J53 | ||

|

|

|

| |||

| 35 feet (12.2 m) | 89J54 | ||||

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

| 50 feet (15.2 m) | 89J55 | |

|

|

|

|

|

|

|

|

|

|

| 20 feet (6.1 m) | 89J56 | |

|

|

|

|

|

| |

3/8” (10 mm) | 3/4” (19 mm) |

| 30 feet (9.1 m) | 89J57 | ||

| ||||||

|

|

|

| |||

| 40 feet (12.2 m) | 89J58 | ||||

|

|

| ||||

|

|

|

|

|

| |

|

|

|

| 50 feet (15.2 m) | 89J59 | |

|

|

|

|

|

|

|

|

|

|

| 30 feet (9.1 m) | 89J60 | |

|

|

|

|

|

| |

3/8” (10 mm) | 7/8” (22 mm) |

| 40 feet (12.2 m) | 89J61 | ||

|

| |||||

|

|

|

|

|

| |

|

|

|

| 50 feet (15.2 m) | 89J62 | |

|

|

|

|

|

|

|

* Applicable to all minor revision numbers unless otherwise specified.

** Some applications may required a

Page 4