Line Set Requirements

This section provides information on: installation of new or replacement line set.

SAdding Polyol ester oil requirements

SNew or replacement line set installation

SUsing existing line set.

ADDING POLYOL ESTER OIL REQUIREMENTS

![]() IMPORTANT

IMPORTANT

Mineral oils are not compatible with HFC−410A. If oil must be added, it must be a Polyol Ester oil.

The compressor is charged with sufficient Polyol Ester oil (POE) for line set lengths up to 50 feet. Recommend adding oil to system based on the amount of refrigerant charge in the system. Systems with 20 pounds or less of refrigerant required no oil to be added.

For systems over 20 pounds − add one ounce for every five

(5) pounds of HFC−410A refrigerant.

Recommended topping−off POE oils are Mobil EAL ARCTIC 22 CC or ICI EMKARATEt RL32CF.

NEW OR REPLACEMENT LINE SET INSTALLATION

Field refrigerant piping consists of both liquid and vapor lines from the outdoor unit to the indoor coil. Use Lennox L15 (sweat, non−flare) series line set, or field−fabricated refrigerant line sizes as specified in table 2.

If refrigerant lines are routed through a wall, then seal and isolate the opening so vibration is not transmitted to the building. Pay close attention to line set isolation during installation of any HVAC system. When properly isolated from building structures (walls, ceilings. floors), the refrigerant lines will not create unnecessary vibration and subsequent sounds. See figure 8 for recommended installation practices.

NOTE When installing refrigerant lines longer than 50 feet, see the Lennox Refrigerant Piping Design and Fabrication Guidelines, CORP. 9351−L9, or contact Lennox Technical Support Product Applications for assistance. To obtain the correct information from Lennox, be sure to communicate the following information:

SModel (XP14) and size of unit (e.g. −036).

SLine set diameters for the unit being installed as listed in table 2 and total length of installation.

SNumber of elbows vertical rise or drop in the piping.

USING EXISTING LINE SET

Things to consider:

SLiquid line that meter the refrigerant, such as RFC1 liquid line, must not be used in this application.

SExisting line set of proper size as listed in table 2 may be reused.

SIf system was previously charged with HCFC−22 refrigerant, then existing line set must be flushed (see Flushing Line Set and Indoor Coil on page 15).

If existing line set is being used, then proceed to Brazing Connections on page 11.

![]() IMPORTANT

IMPORTANT

Lennox highly recommends changing line set when converting the existing system from HCFC−22 to HFC−410A. If that is not possible and the line set is the proper size as reference in table 2, use the procedure outlined under Flushing Line Set and Indoor Coil on page 13.

![]() IMPORTANT

IMPORTANT

If this unit is being matched with an approved line set or indoor unit coil which was previously charged with mineral oil, or if it is being matched with a coil which was manufactured before January of 1999, the coil and line set must be flushed prior to installation. Take care to empty all existing traps. Polyol ester (POE) oils are used in Lennox units charged with HFC−410A refrigerant. Residual mineral oil can act as an insulator, preventing proper heat transfer. It can also clog the expansion device, and reduce the system performance and capacity.

Failure to properly flush the system per the instructions below will void the warranty.

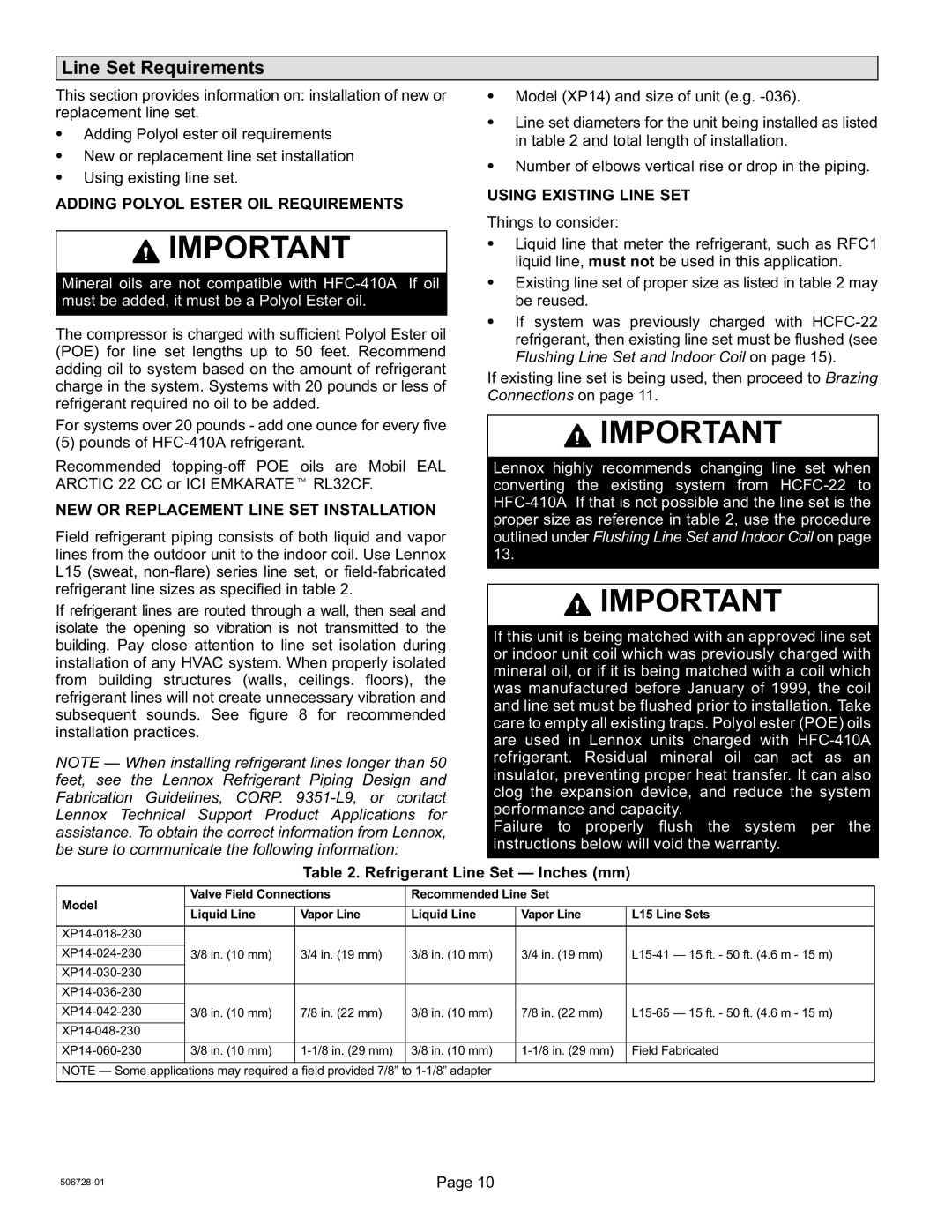

Table 2. Refrigerant Line Set

Model | Valve Field Connections | Recommended Line Set |

| ||

|

|

|

|

| |

| Liquid Line | Vapor Line | Liquid Line | Vapor Line | L15 Line Sets |

|

|

|

|

|

|

XP14−018−230 |

|

|

|

|

|

|

|

|

|

|

|

XP14−024−230 | 3/8 in. (10 mm) | 3/4 in. (19 mm) | 3/8 in. (10 mm) | 3/4 in. (19 mm) | L15−41 |

|

|

|

|

|

|

XP14−030−230 |

|

|

|

|

|

|

|

|

|

|

|

XP14−036−230 |

|

|

|

|

|

|

|

|

|

|

|

XP14−042−230 | 3/8 in. (10 mm) | 7/8 in. (22 mm) | 3/8 in. (10 mm) | 7/8 in. (22 mm) | L15−65 |

|

|

|

|

|

|

XP14−048−230 |

|

|

|

|

|

|

|

|

|

|

|

XP14−060−230 | 3/8 in. (10 mm) | 1−1/8 in. (29 mm) | 3/8 in. (10 mm) | 1−1/8 in. (29 mm) | Field Fabricated |

|

|

|

|

|

|

NOTE |

|

|

|

|

|

|

|

|

|

|

|

506728−01 | Page 10 |