Contents

SERVICE MANUAL

CHASSIS LD21B

READ THE SAFETY PRECAUTIONS IN THIS MANUAL

http//aic.lgservice.com

SAFETY PRECAUTIONS

CONTENTS

SERVICING PRECAUTIONS

SPECIFICATION

IMPORTANT SAFETY NOTICE

SAFETY PRECAUTIONS

Electrostatically Sensitive ES Devices

SERVICING PRECAUTIONS

Replacement

IC Remove/Replacement

Small-Signal Discrete Transistor Removal/Replacement

Removal

4. Model General Specification

SPECIFICATION

1. Application range

3. Test method

symbolrate

Symbolrate 4.0Msymbols/s to 7.2Msymbols/s

DVB-S2 8PSK / QPSK 2 ~ 45Msymbol/s

DVB-S QPSK 2 ~ 45Msymbol/s

5.1. Component Input Y, CB/PB, CR/PR

5. Video resolutions 2D

5.2. RGB Input PC

PCDVI

5.3. HDMI InputPC/DTV

Boot file Download

ADJUSTMENT INSTRUCTION

1. Application Range

2. Designation

3.3. EDID data

3.1. ADC Process

3.2. EDID Download

7. ADC Calibration

4.1. Adjustment Preparation

4. Total Assembly line process

3.4 Function Check

6.1. Signal Table

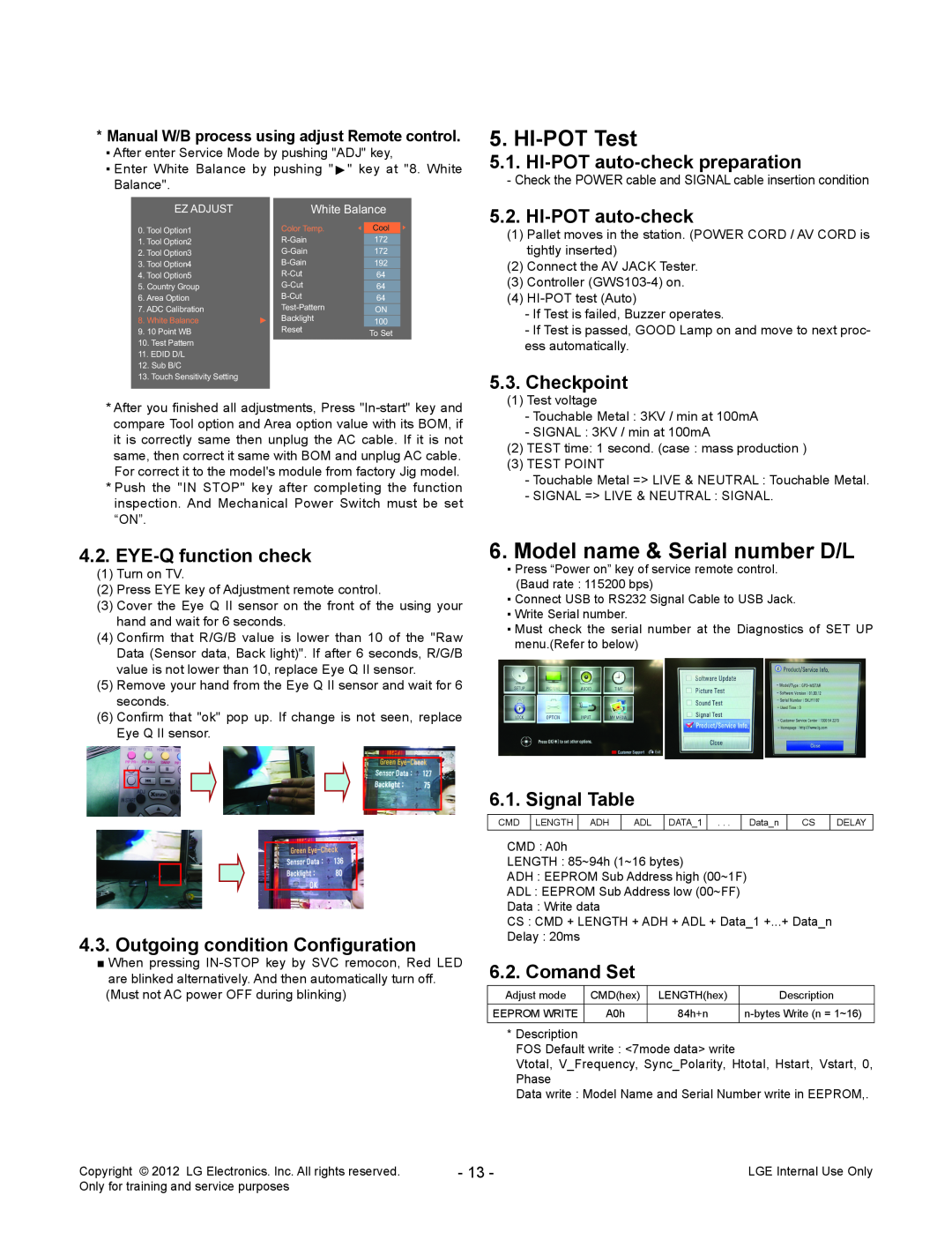

4.3. Outgoing condition Configuration

5. HI-POT Test

6. Model name & Serial number D/L

6.3. Method & notice

7. MAC Address & CI+ key download

7.1 MAC Address

GP4LOW

7.3. LAN PORT INSPECTIONPING TEST

7.2 LAN Inspection

Screw specification and application situation

SCREW ASSEMBLY WORKING GUIDE

ח ͷͲͳͤͤͤͪͥͣ͢͡ ͙;ͤ͛ͽͥͦ͑͟͝ͳͼ͑͝;ΒΔΙΚΟΖ͚ ח ͣ͢ͶͲ

ח ͷͲͳͤͨͩͩͣ͑͢͡͡ ͙;ͧ͛ͽ͑͢͡͝ͳͼ͑͝;ΒΔΙΚΟΖ͚

Rear

BLOCK DIAGRAM

Side

LG2111 A

EXPLODED VIEW

Copyright 2012 LG Electronics. Inc. All rights reserved

GP4LS7LR22011.12.01

to delete CI or gate for

for SYSTEM EEPROM

VDDC

Normal Power

Normal

DDR3

PowerDET

FROM LIPS & POWER B/D

+3.3VNormal

+1.5VDDR

IR/LED and control for normal models

USB1DIODES

USB SIDE

USB2DIODES

HDMI

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

RGB-PC / SPDIF

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

COMMERCIAL/NonOS MODEL OPTION COMMERCIAL MODEL OPTION

RS-232C

For Comsumer model, use 4PIN Wafer

LVDS for large inch

GP4LS7LR22011/06/03 DDR25612

S7LR2DIVXMS10

IC1201

H5TQ1G63DFR-H9C

SFLASHMAINMACRONIX

Serial Flash for SPI boot

SFLASHMAINWINBOND IC1401-*1 W25Q80BVSSIG

PHONE

Headphone *Option HEADPHONE

HEAD

Option name of this page CISLOT because of Hong Kong

CI Region

10067972-0500LF

GP4LS7LR22011/06/14 ETHERNET21

H/W option ETHERNET

ETHERNET

TU2602TU2603 TDSS-G101D TDSN-G301D

GP4RGLOBALTUNERBLOCK

TU2601

TDSQ-G001D

OptionLNB

DVB-S2 LNB Part Allegro

GP4LS7LR22011/11/02 DVBS27

DCDCGND and AGND are connected

FULL SCART / COMPONENT1

SCART / COMPONENT&COMPSIT

JK2801

PSC008-01

AUDIO AMPSTA380BWE

Page

Contents of LCD TV Standard Repair Process

Continue to the next page

Contents of LCD TV Standard Repair Process Detail Technical Manual

Error symptom

Content

LCD TV

A. Video error

Main B/D↔ Power B/D, LVDS Cable,Speaker Cable,IR B/D Cable

A2 Check Power Board 24v output

Check various

voltages of Power

Board 3.5V,12V,20V

or 24V…

Menu→ Set up→ Support → Signal Test Signal strength Normal over 50%

By using Digital signal level meter By using Diagnostics menu on OSD

Signal Quality Normal over 50%

→ Set-Top-Box, Different maker TV etc

Check color by input -External Input COMPONENT -RGB

A8/ A9

※ Check

Link Cable

Vertical/Horizontal bar, residual image, light spot

External device screen error-Color error

Connect other external device and cable

Check color condition by input -External Input -Component RGB

Check Power LED

B. Power error

Check Power On ‘”High”

Measure voltage of each output of Power B/D

If Power Off mode is not displayed Check Power B/D voltage

Check Power Off Mode

POWEROFFABNORMAL1

POWEROFFCPUABNORMAL

24V of Power

C. Audio error

Check user menu Speaker off

Check audio B+

Check audio B+ Voltage

In case of External Input signal error Check and fix external device

1. Remote controlR/C operating error

D. Function error

Check & Repair

Y Check technical Signal information input? - Fix information

Check input signal

Recognition error

Replace Main B/D

Identify nose type

E. Noise

F. Exterior defect